Fibre structure of carbon nano tube/nano oxide nano composite material and preparation method and use thereof

A nano-composite material and composite fiber technology, applied in the fields of botanical equipment and methods, materials for heat exchange, chemical instruments and methods, etc., can solve the problem of difficult application, difficulty in fixing and separating nanoparticles, and easy aggregation of nanoparticles. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

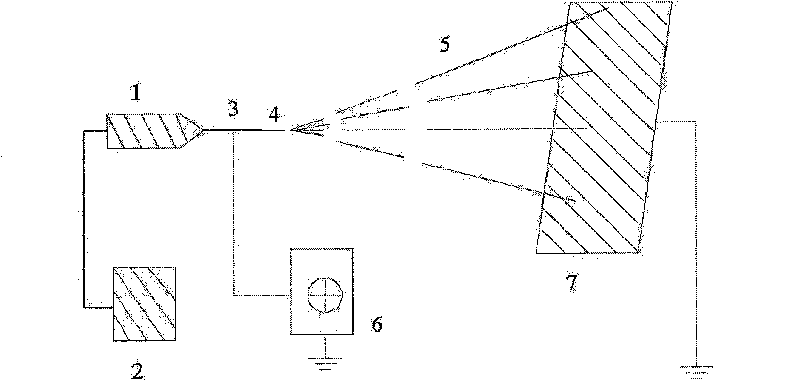

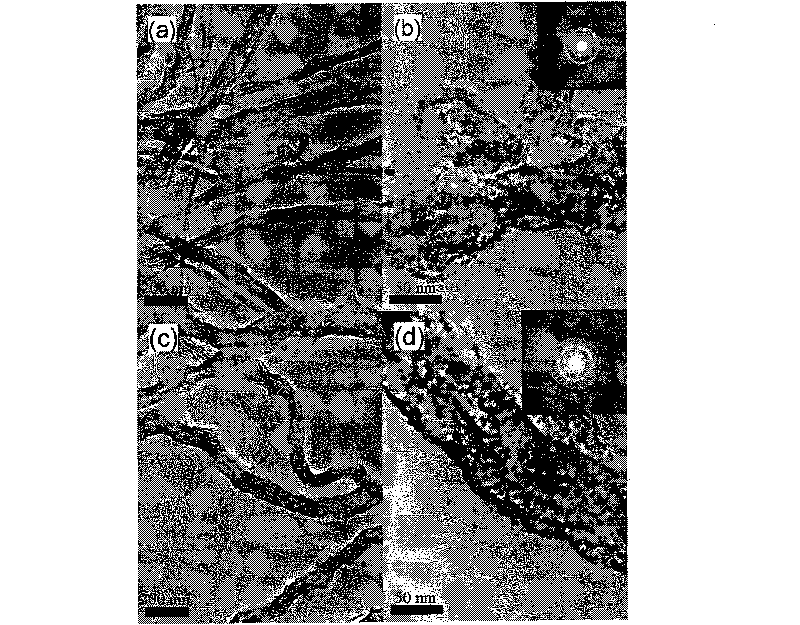

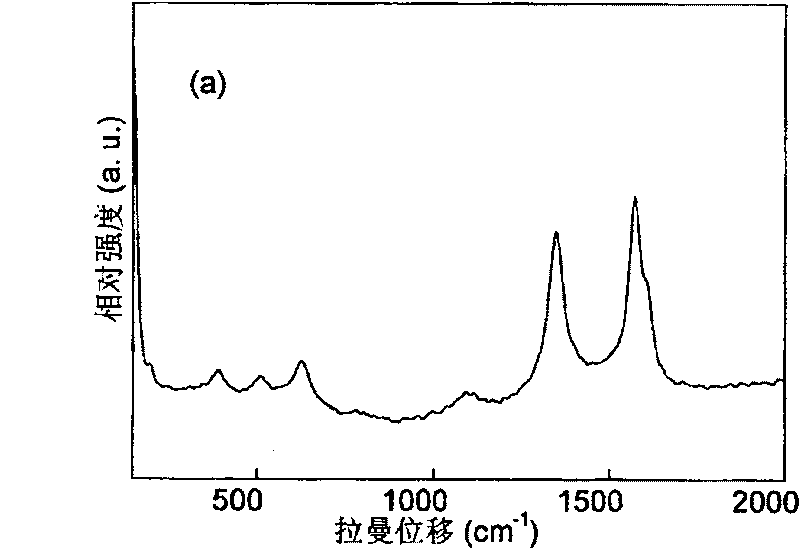

[0056]15 parts by weight of carbon nanotubes (diameter 10-20nm, length 1-10μm) are dispersed in 100 parts by weight of ethanol by ultrasound, then 100 parts by weight of n-butyl titanate are added, and after mixing, 150 parts by weight of nano oxides are added to form As auxiliary agent acetic acid, after magnetically stirring for 0.5 h, the dispersion was mixed with 100 parts by weight of ethanol solution in which 30 parts by weight of polyvinylpyrrolidone was dissolved, and mixed uniformly after magnetically stirring for 1 hour to obtain a dispersion. Then the dispersion is contained in the liquid storage tank of the metering pump, and the resulting fiber (polyvinylpyrrolidone / carbon nanotube / titanium dioxide precursor) is collected at a sample injection rate of 1mL / h under the condition of an electric field strength of 1kV / cm on a grounded aluminum foil collector plate. Then, the polyvinylpyrrolidone is removed by calcining at 300-800° C. for 1 h, and finally a carbon nanot...

Embodiment 2

[0058] 10 parts by weight of fluorinated single-walled carbon nanotubes (diameter 1-2nm, length 0.5-5μm) are dispersed in 100 parts by weight of water by ultrasound, then 50 parts by weight of isopropyl titanate are added, and 10 parts by weight of nanometer Hydrochloric acid as an auxiliary agent for oxide formation, after magnetic stirring for 1 hour, the dispersion was mixed with 100 parts by weight of ethanol solution in which 30 parts by weight of polyvinyl acetate was dissolved, and after magnetic stirring for 1 hour, the mixture was uniformly mixed to obtain a dispersion. Then the dispersion is contained in the liquid storage tank of the metering pump, with a sample injection speed of 1mL / h, under the condition of an electric field strength of 3kV / cm, the obtained fiber (polyvinyl acetate / carbon nanotube / titanium dioxide precursor) Collect on a grounded aluminum foil collection plate. Then, polyvinyl acetate / carbon nanotubes / titanium dioxide hybrid nanofibers were obtai...

Embodiment 3

[0060] 10 parts by weight of a mixture of single-walled carbon nanotubes and multi-walled carbon nanotubes (1 to 20 nm in diameter and 1 to 15 μm in length) are dispersed in 100 parts by weight of ethanol by ultrasonic waves, then 50 parts by weight of zirconium acetate are added, and stirred under magnetic conditions for 0.5 h Finally, the dispersion was mixed with 100 parts by weight of ethanol solution in which 20 parts by weight of polyvinyl alcohol was dissolved, and mixed evenly after magnetic stirring for 10 hours to obtain a dispersion. Then the dispersion was filled in the liquid storage tank of the metering pump, and the mixture was mixed at a rate of 5 mL / h. The injection speed is 2kV / cm, and the obtained fibers (polyvinyl alcohol / carbon nanotubes / zirconia) are collected on a grounded aluminum foil collection plate. Then, they are removed by calcining at 600°C for 1h Polyvinyl alcohol, and finally get the carbon nanotube / zirconia hybrid nanofiber film. The carbon nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com