Method for deodorant waste lye for absorbing treating smoke

A waste lye and deodorization technology, which is applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of low heat transfer efficiency and high equipment cost, and achieve increased heat transfer coefficient, easy operation, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

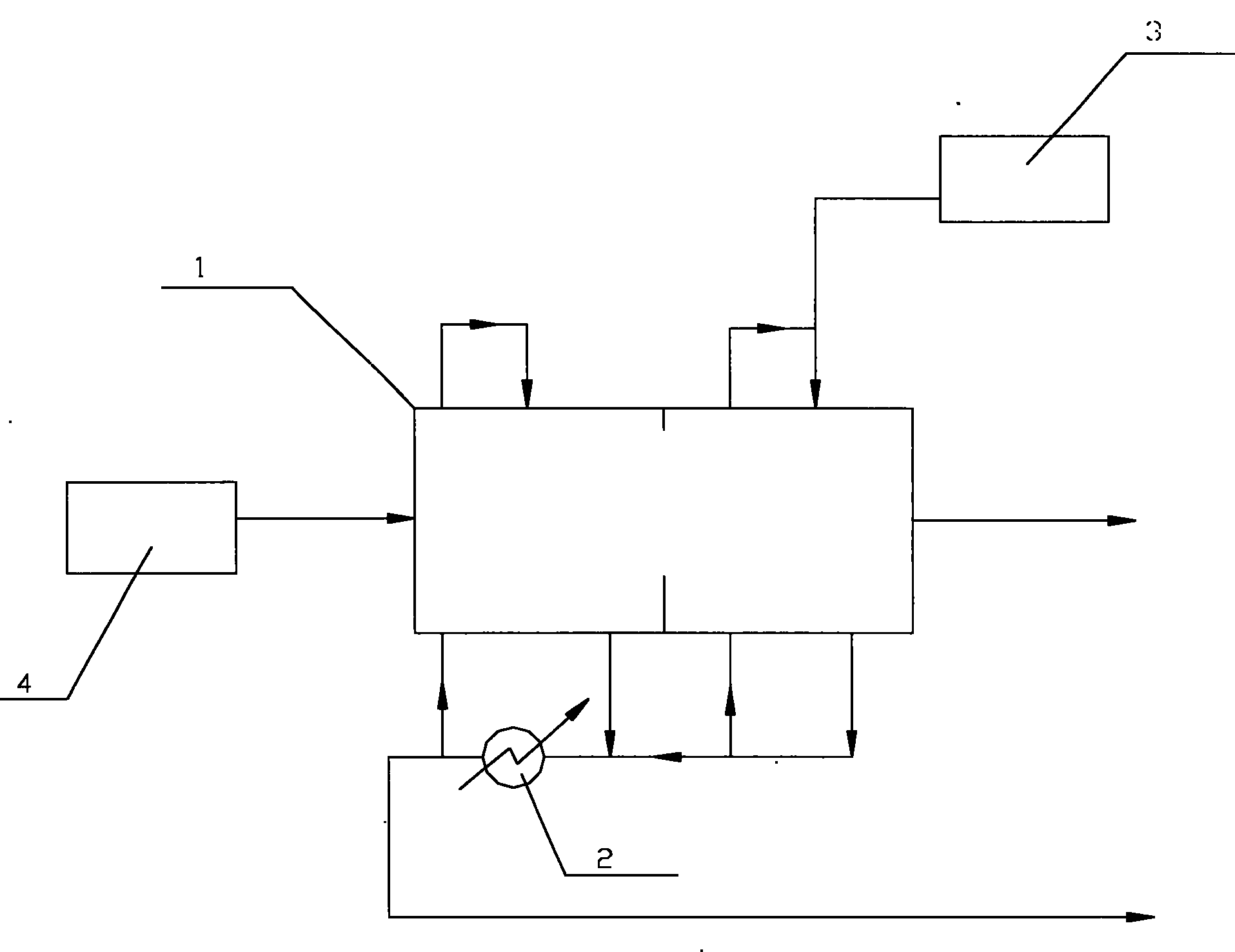

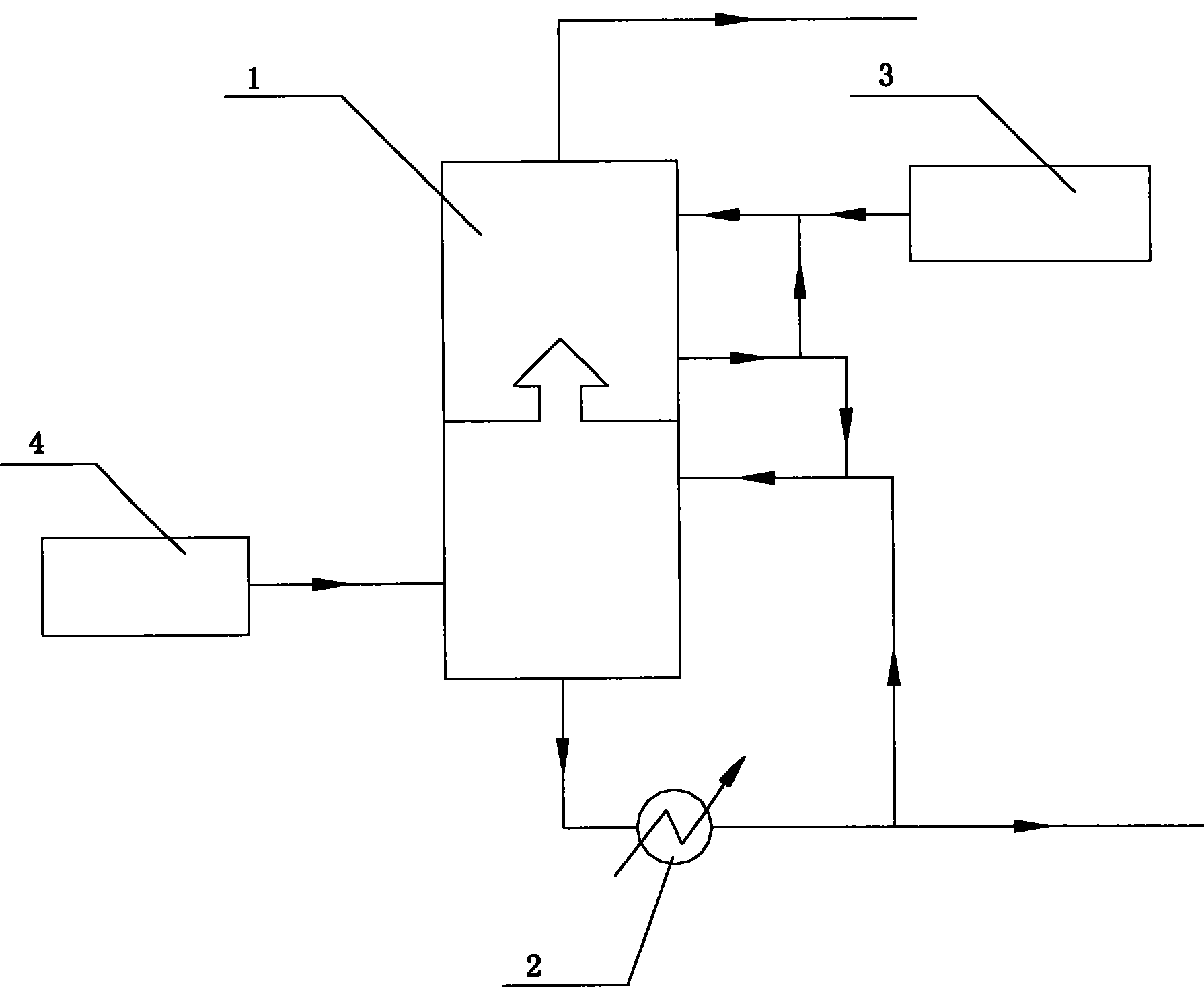

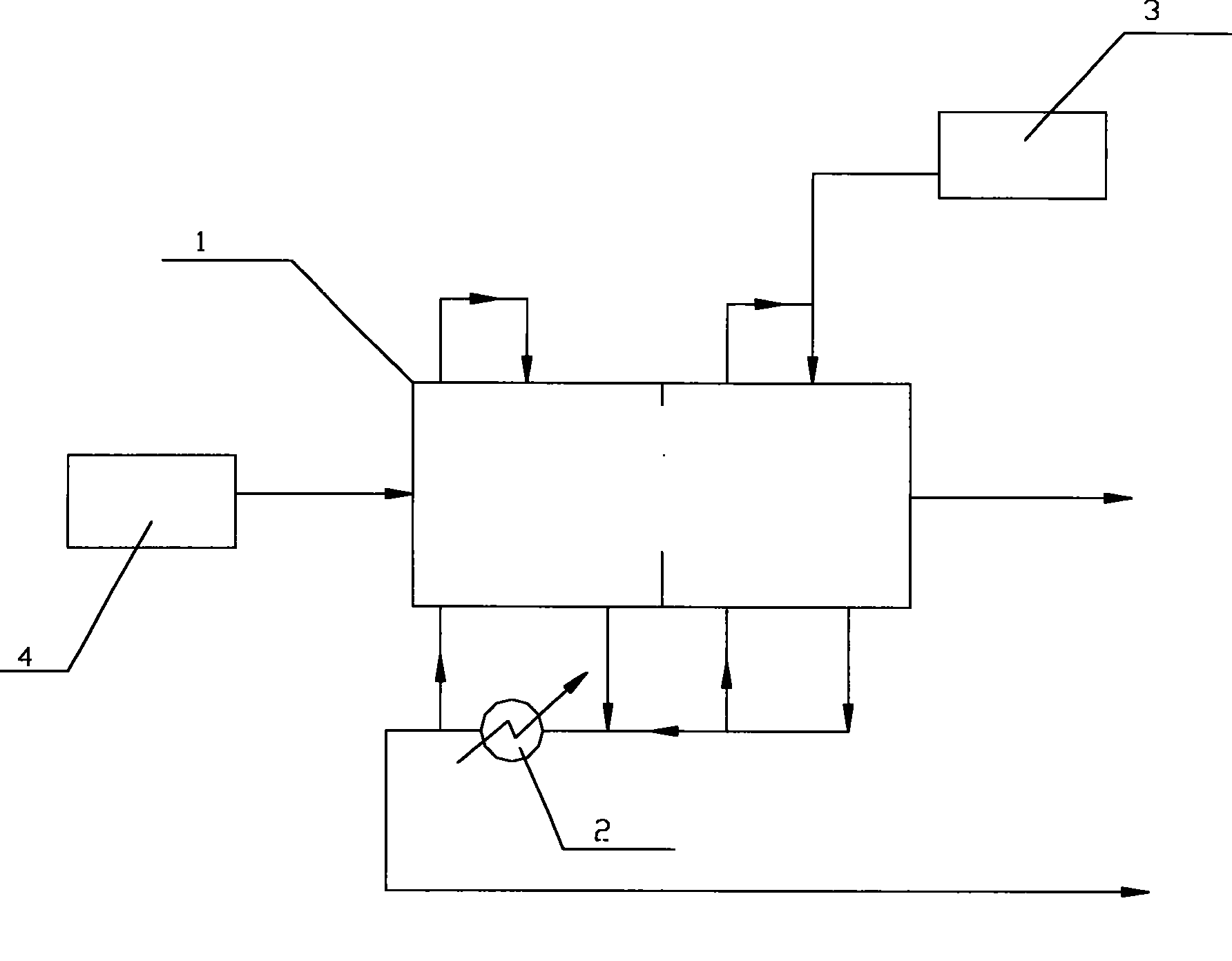

Method used

Image

Examples

Embodiment 1

[0023] The 190°C flue gas produced by the oil-fired boiler contains 3250 mg / m of sulfur dioxide after dust removal 3 ;Smoke dust is 305mg / m 3 ; Nitrogen oxide is 610mg / m 3 . In the petrochemical production process, ethylene alkali is used to refine the deodorized lye, the temperature is 25°C, and the COD is 4000mg / L; the sulfide is 5mg / L; the alkalinity (mass fraction of sodium hydroxide) is 3%. Under the following processing conditions, it is processed by the process of the present invention.

[0024] During the first stage (front stage) absorption process, the temperature of the flue gas at the outlet of the first stage is controlled to be 60°C, and the space velocity of the flue gas in the first stage of absorption is 1500h -1 , the liquid-gas ratio is 0.05, and the pH value of the discharge liquid is 5.5. The air velocity of the flue gas in the second stage (rear stage) absorption is 1000h -1 , the liquid-to-gas ratio is 4, the flue gas outlet temperature is 50°C, and...

Embodiment 2~5

[0027] Using different process conditions to treat flue gas with different concentrations, the conditions and treatment results are shown in Table 1. As can be seen from Table 1, the method of the present invention can use the deodorized waste lye after wet oxidation treatment to "treat waste with waste" to treat various flue gases containing pollutants such as sulfur dioxide, soot, and nitrogen oxides. The entire treatment process is perfect, and the flue gas after treatment can meet the emission standard.

[0028] Table 1 embodiment 2~5 treatment conditions and result

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com