Polyaniline coated magnetic carbon-nano tube composite material and preparation method thereof

A technology of magnetic carbon nanotubes and composite materials, applied in the field of nanomaterials, can solve the problems of easy oxidative discoloration of nano-iron tetroxide, reduced electrical conductivity of materials, easy detachment of nano-iron tetroxide particles, etc., and achieves good application prospects, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

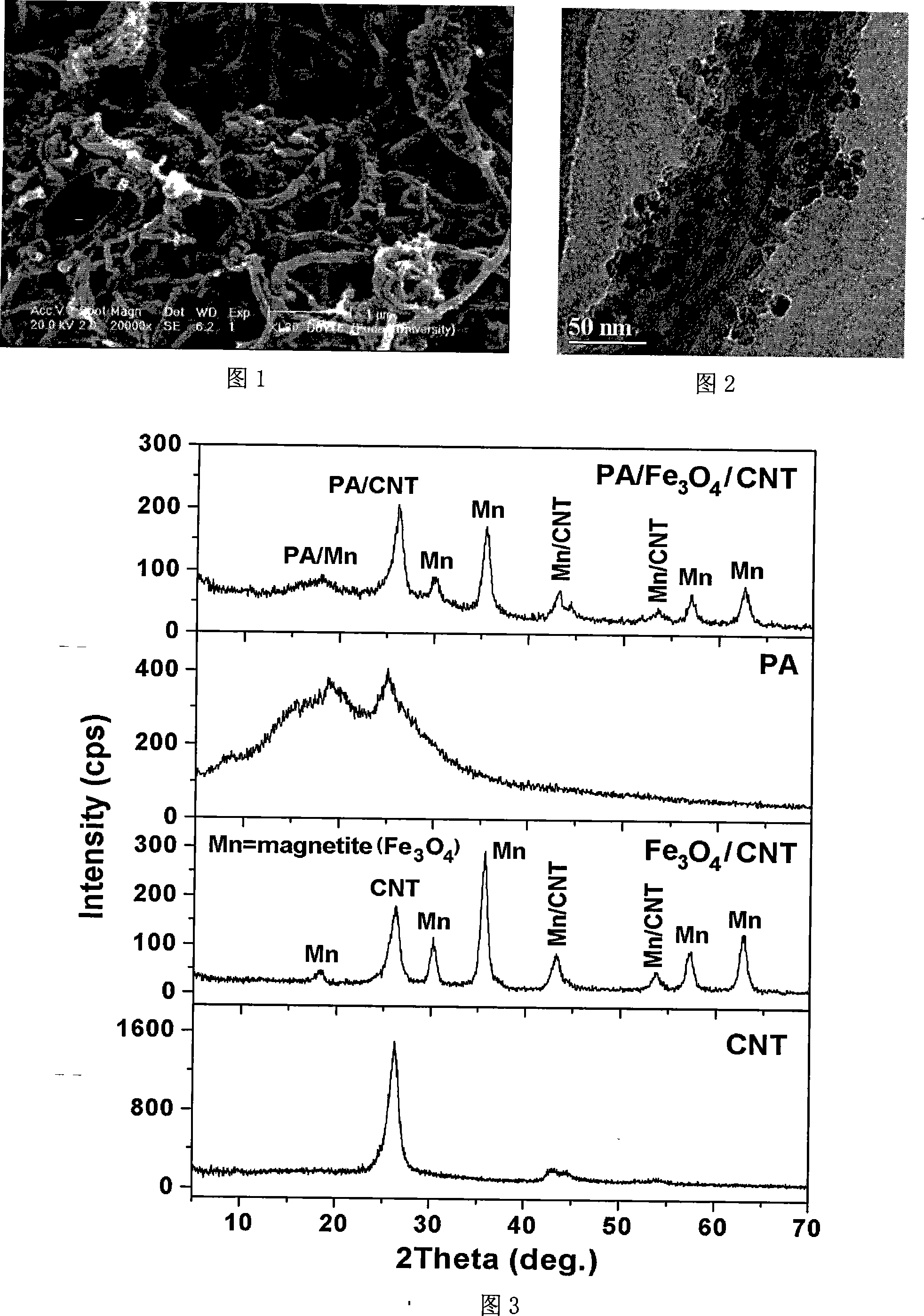

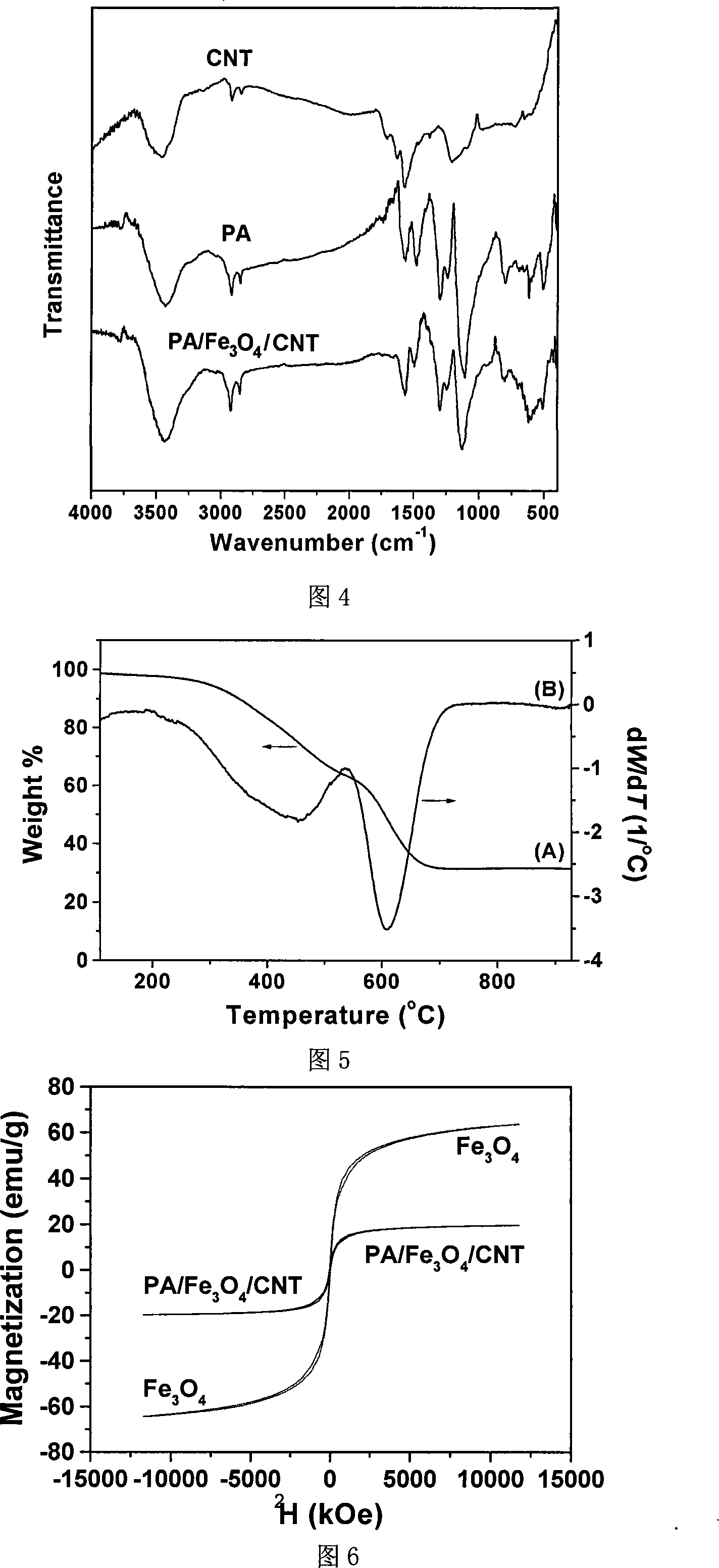

[0018] 1. Preparation and characterization of polyaniline-wrapped magnetic carbon nanotube composites

[0019] 375 mg (40 mmol) ammonium iron (III) sulfate (NH 4 Fe(SO 4 ) 2 12H 2 O) and 156 mg (20 mmol) ammonium ferrous sulfate (II) ((NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O) be dissolved in 20 milliliters of deionized water, wherein the mol ratio of ferric ion and ferrous ion is 2: 1, the total concentration of ferric ion and ferric ion is about 60mmol / L, then more than 90mg Wall carbon nanotubes (diameter 40-60 nanometers, length 5-15 microns, purity greater than 95%, Shenzhen Nano Harbor Co., Ltd.) are placed in the solution, ultrasonically dispersed for 15 minutes to obtain a black suspension solution, and then in the solution Add 1.5 milliliters of concentrated ammonia water (mass percent concentration 25-28%) dropwise, mechanically stir while adding, then this mixed solution is heated in 50 ℃ of water baths with water for 30 minutes, the magnet is placed on the bottom that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com