Nifedipine controlled-releasing tablet and preparation method thereof

A technology for nifedipine and nifedipine, which is applied to pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc. Changes in physical and chemical properties of polyoxyethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

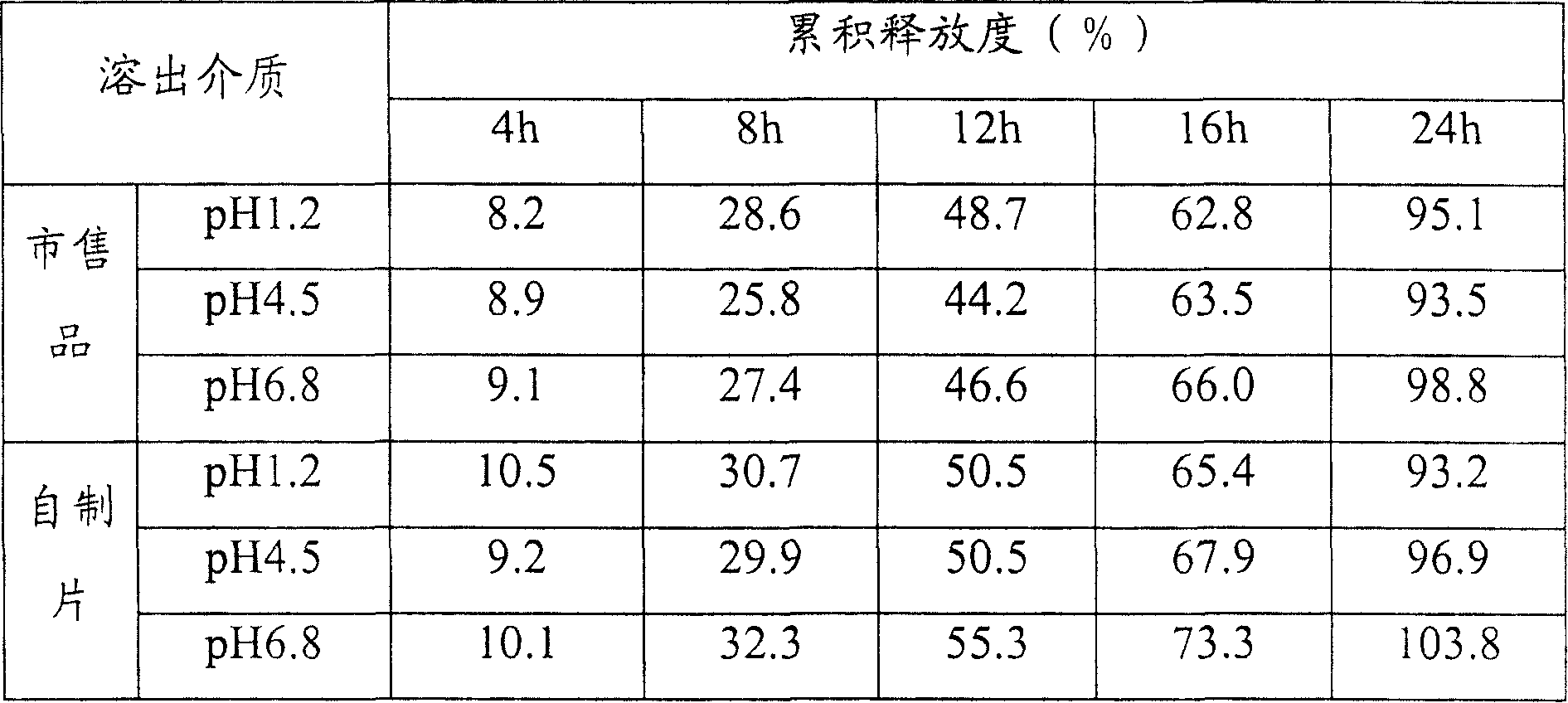

Image

Examples

Embodiment 1

[0046] The prescription is as follows:

[0047] (1) Drug-containing layer (per tablet):

[0048] Nifedipine 33mg

[0049] Povidone (Plasdone K-90D) 20mg

[0050] Copovidone (Plasdone S630) 61mg

[0051] (2) Booster layer (per piece):

[0052] Carboxymethyl Starch Sodium 35mg

[0053] Hypromellose (K15M) 30mg

[0054] Carbomer (971PNF) 10mg

[0056] Copovidone (Plasdone S630) 15mg

[0057] Red Iron Oxide 1.1mg

[0058] (3) Coating solution of film containing semi-permeable material (also known as semi-permeable film coating or semi-permeable film coating)

[0059] Cellulose acetate 59.5mg

[0060] Diethyl phthalate 3mg

[0061] Acetone 1.5ml, single tablet weight increased to 38mg.

[0062] (4) Composition of moisture-proof coating solution:

[0063] Color blue pink (CM-0317) Appropriate amount

[0064] Preparation Process:

[0065] 1. Preparation of drug-containing layer particles:

[0066] Avoid light operation. After all the mat...

Embodiment 2

[0075] The prescription is as follows:

[0076] (1) Drug-containing layer (per tablet):

[0077] Nifedipine 33mg

[0078] Povidone (Plasdone K-90D) 30mg

[0079] Copovidone (Plasdone S630) 91mg

[0080] Magnesium Stearate 1.5mg

[0081] Micronized silica gel 0.5mg

[0082] (2) Booster layer (per piece):

[0083] Sodium starch glycolate 37mg

[0084] Hypromellose (K15M) 30mg

[0085] Carbomer (971PNF) 8mg

[0086] Sodium chloride 21mg

[0087] Copovidone (Plasdone S630) 15mg

[0088] Red Iron Oxide 1.1mg

[0089] Magnesium stearate 0.6mg

[0090] Micronized silica gel 0.4mg

[0091] (3) Composition of semi-permeable membrane coating solution (for every 1000 tablets)

[0092] Cellulose acetate 59.5g

[0093] Diethyl phthalate 3g

[0094] Acetone 1500ml

[0095] Single tablet weight gain 38mg

[0096] (4) Composition of moisture-proof coating solution:

[0097] Color blue pink (CM-0317) Appropriate amount

[0098] Wherein povidone (Plasdone K-90D) can also be rep...

Embodiment 3

[0112] The preparation process is the same as in Example 2. The prescription is as follows:

[0113] (1) Drug-containing layer (per tablet):

[0114] Nifedipine 33mg

[0115] Povidone (Plasdone K-90D) 70mg

[0116] Magnesium Stearate 1.2mg

[0117] Micronized silica gel 0.5mg

[0118] (2) Booster layer (per piece):

[0119] Sodium starch glycolate 15mg

[0120] Hypromellose (K15M) 35mg

[0121] Carbomer (971PNF) 13mg

[0122] Sodium chloride 35mg

[0123] Copovidone (Plasdone S630) 25mg

[0124] Red Iron Oxide 1.1mg

[0125] Magnesium stearate 0.6mg

[0126] Micronized silica gel 0.4mg

[0127] (3) The composition of the semi-permeable membrane coating solution contains cellulose acetate and diethyl phthalate; then it is coated with a film moisture-proof coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com