Method for producing ultra-high solid content hydroxy acrylic resin

A hydroxyacrylic acid, ultra-high solid content technology, applied in the direction of coating, can solve the problems of large motion resistance, serious intermolecular entanglement, difficult application and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

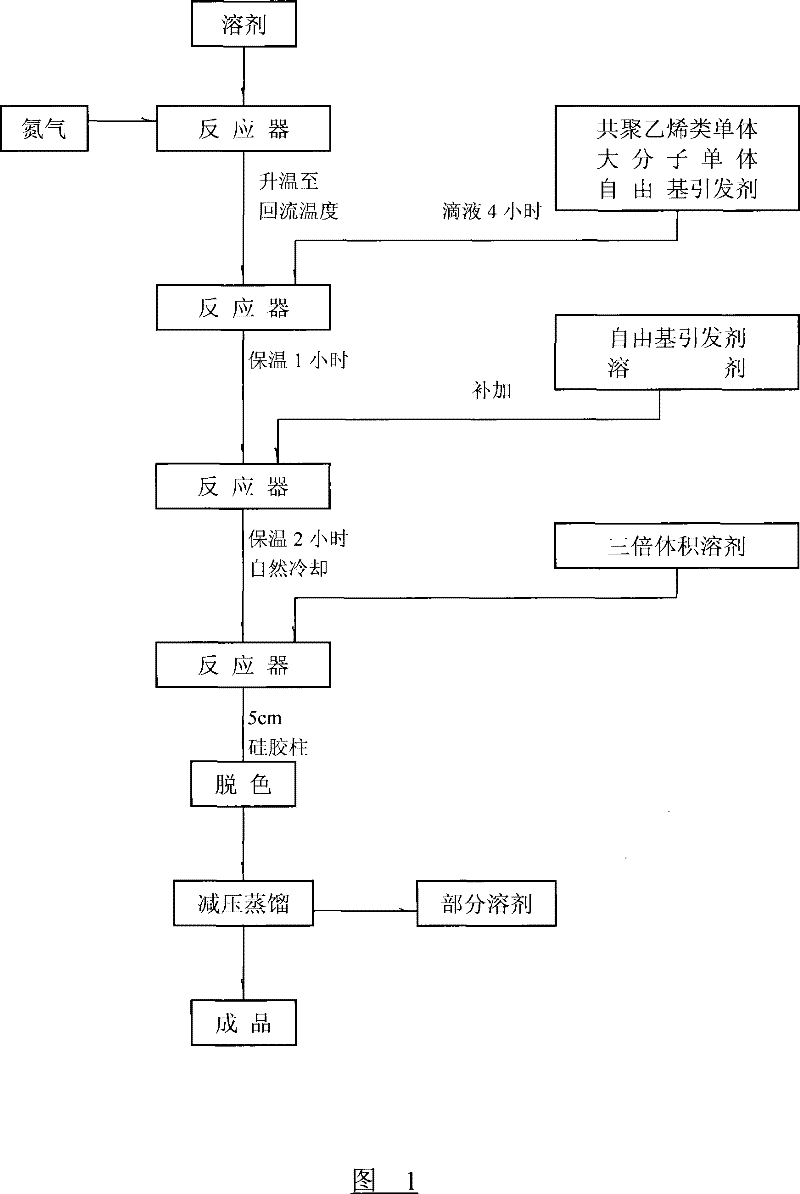

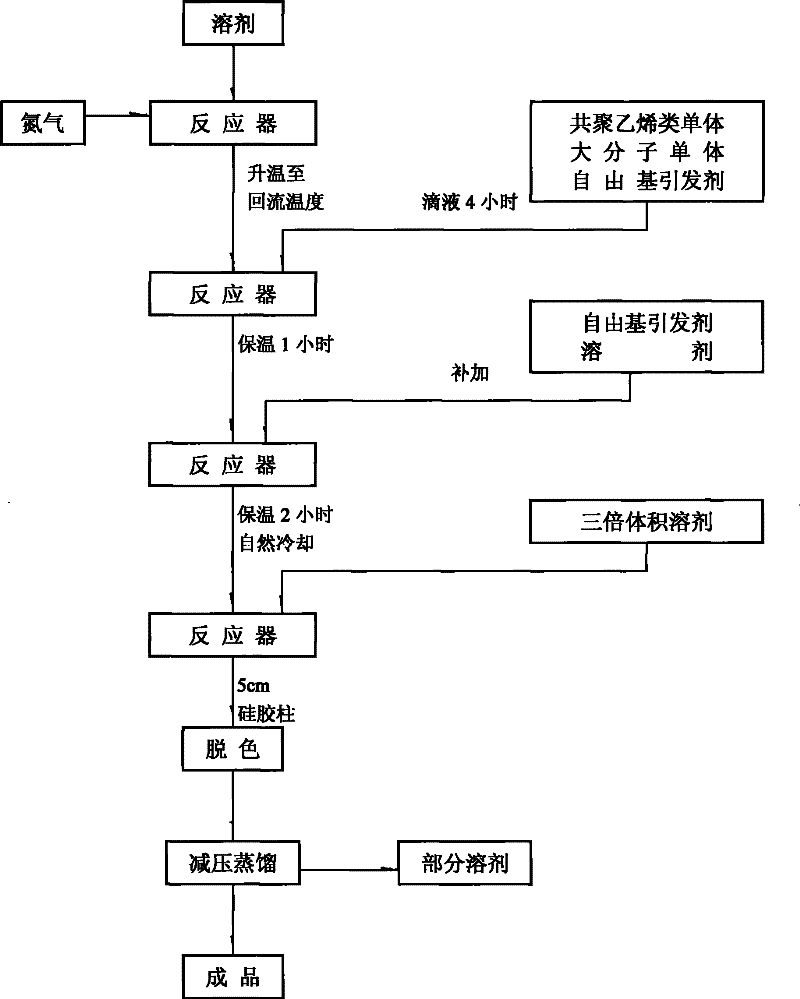

Method used

Image

Examples

Embodiment 1

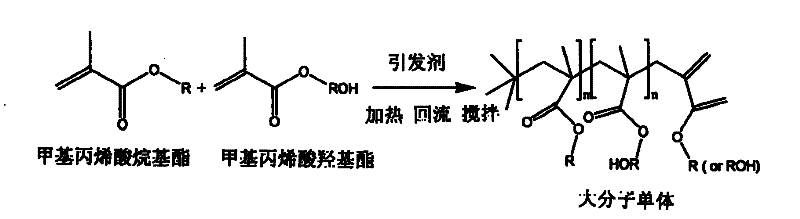

[0088] Preparation of methyl methacrylate (MMA) / butyl methacrylate (BMA) / hydroxyethyl methacrylate (HEMA) macromonomer (Macromonomer-1): MMA 100g / HEMA 130g / BMA 160g with 167g acetic acid Butyl ester, 1.95g AIBN, 78.5mg COPhBF (dihydrate bis(difluoride benzodiketoxime) cobaltate (II) salt) were mixed evenly, then added to the reaction bottle, heated and stirred at 75°C under nitrogen atmosphere, and reacted for 5h . The solid content of the product is 65%, and the conversion rate is 93%. GPC results Mn = 3097, Mw / Mn = 1.75.

[0089] Add 60g of butyl acetate and 1.5g of AIBN into the three-necked flask, wait until the initiator is completely dissolved and heat up to 75°C, then mix 300g of the obtained Macromonomer-1 solution with 31.5g of styrene (St), 31.5g of hydroxyethyl acrylate (HEA), 36.75 g methyl acrylate (MA) and 5.25 g acrylic acid (AA) were mixed evenly and then slowly added dropwise into the flask through a constant pressure dropping funnel for 4 h, and then 15 g o...

Embodiment 2

[0091] Preparation of MMA / BMA / HEMA macromonomer (Macromonomer-2): MMA100g / HEMA 130g / BMA 160g mixed with 167g butyl acetate, 1.95g AIBN, 100mgCOPhBF and added to the reaction flask, heated at 75°C under nitrogen atmosphere Stirring, reaction 5h. The solid content of the product is 62%, and the conversion rate is 89%. GPC results Mn = 1581, Mw / Mn = 1.56.

[0092] Add 60g of butyl acetate and 1.5g of AIBN into the three-neck flask, wait until the initiator is completely dissolved and heat up to 75°C, then mix 300g of the obtained Macromonomer-2 solution with 31.5g St, 31.5g HEA, 36.75g MA, 5.25g AA Slowly drop it into the flask through a constant pressure dropping funnel for 4 hours, add 15 g of butyl acetate and 0.25 g of AIBN after insulated for 1 hour, and incubate for 2 hours. After natural cooling, it was mixed with 3 times the volume of butyl acetate and passed through a 5 cm high silica gel column for decolorization, and then the solvent was distilled off under reduced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com