Method for preparing biocompatible cellulose functionalized carbon nano tube

A technology of biocompatibility and carbon nanotubes, which is applied in the field of preparation of nanotechnology, can solve the problems of occupancy of hydroxyl active sites, increase of reaction steps, increase of use cost, etc., and achieves good biocompatibility and strong controllability. , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

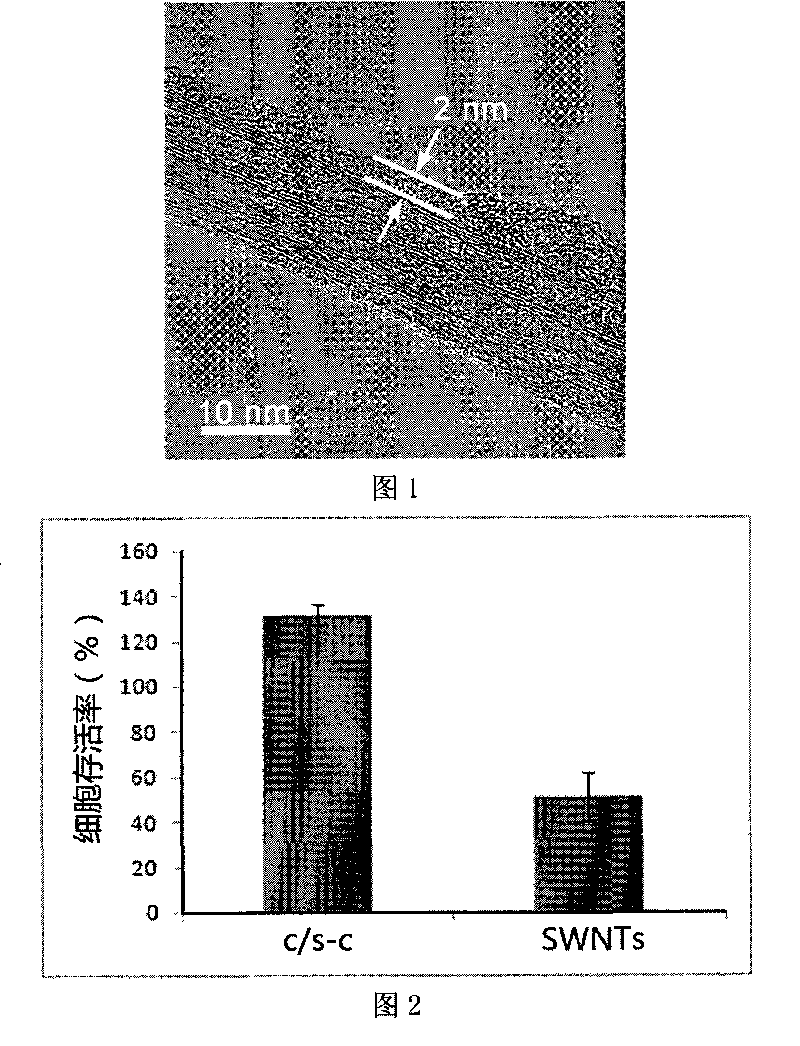

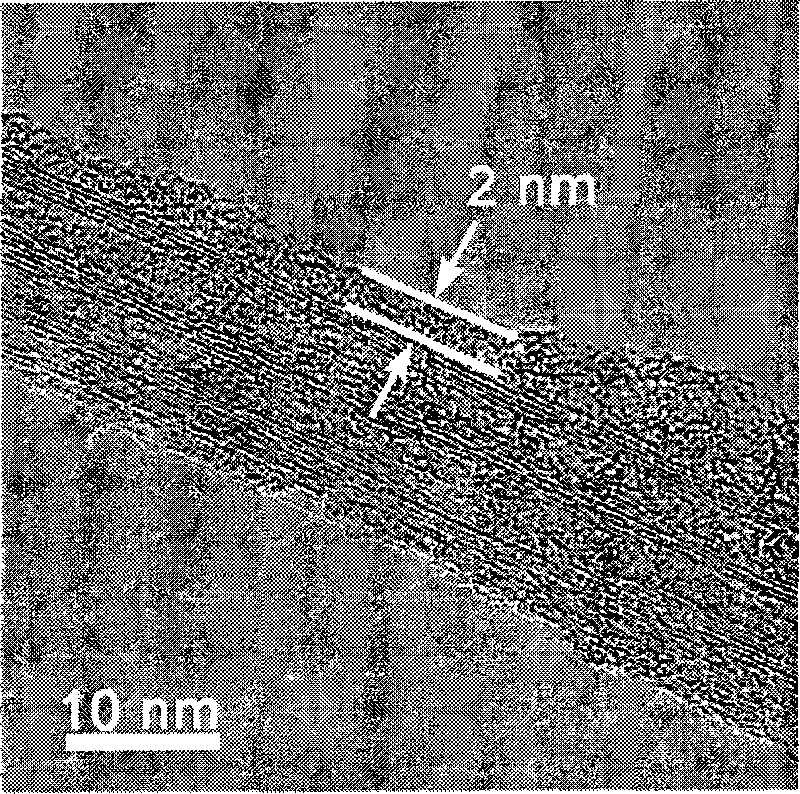

[0028] Using single-walled carbon nanotubes prepared by chemical vapor deposition as the initial raw material, in the ionic liquid reaction phase, cellulose molecules are functionalized onto the surface of single-walled carbon nanotubes through non-covalent physical coating to obtain biocompatibility cellulose-functionalized carbon nanotubes.

[0029] Step a: Add 0.60 mol of methylimidazole to a single-necked round-bottomed flask equipped with a magnetic stirring rotor, seal it with an inversion rubber stopper, then repeatedly pump argon gas three times, and inject it with a syringe under magnetic stirring at room temperature. Add 0.65mol butyl bromide to the flask in 5 batches, then bring the oil bath to 50°C, continue magnetic stirring for 12h, add the product into 200mL ethyl acetate, shake, wash, and separate liquids, repeat 5 times, and statically dissolve in 200mL of acetonitrile Place, recrystallize, and obtain ionic liquid 1-butyl-3-methylimidazole bromide ([BMIM]Br) a...

Embodiment 2

[0035]Using single-walled carbon nanotubes prepared by catalytic pyrolysis as the initial raw material, in the ionic liquid reaction phase, the cellulose molecules are functionalized onto the surface of single-walled carbon nanotubes through non-covalent physical coating to obtain biocompatibility cellulose-functionalized carbon nanotubes.

[0036] Step a: Add 0.90 mol of methylimidazole to a single-necked round-bottomed flask equipped with a magnetic stirring rotor, seal it with a rubber stopper, pump and fill it with argon gas repeatedly for 3 times, and inject it with a syringe under magnetic stirring at room temperature. Add 1.20mol chlorobutane to the flask in 10 batches, then bring the oil bath to 70°C, continue magnetic stirring for 18h, add the product into 200mL ethyl acetate, shake, wash, and separate liquids, repeat 5 times, and statically dissolve in 200mL of acetonitrile Place, recrystallize, obtain ionic liquid chloride 1-butyl-3-methylimidazole ([BMIM]Cl) after ...

Embodiment 3

[0040] Using single-walled carbon nanotubes prepared by catalytic pyrolysis as the initial raw material, in the ionic liquid reaction phase, the cellulose molecules are functionalized onto the surface of single-walled carbon nanotubes through non-covalent physical coating to obtain biocompatibility cellulose-functionalized carbon nanotubes.

[0041] Step a: Add 0.5 mol of methylimidazole to a single-necked round-bottomed flask equipped with a magnetic stirring rotor, seal it with an inversion rubber stopper, then repeatedly pump argon gas three times, and inject it with a syringe under magnetic stirring at room temperature. Add 0.75mol chlorohexane in 2 batches to the flask, then bring the oil bath to 75°C, continue magnetic stirring for 20h, add the product into 200mL ethyl acetate, shake, wash, and separate liquids, repeat 5 times, and statically dissolve in 200mL of acetonitrile place, recrystallize, and obtain ionic liquid chloride 1-hexyl-3-methylimidazole ([HMIM]Cl) afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com