Method for synthesizing manganese octahedron molecular screen by ultrasound

An octahedral molecular sieve, ultrasonic synthesis technology, applied in molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of mixed materials with impurity phase, long reaction time, etc., to improve efficiency and shorten preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

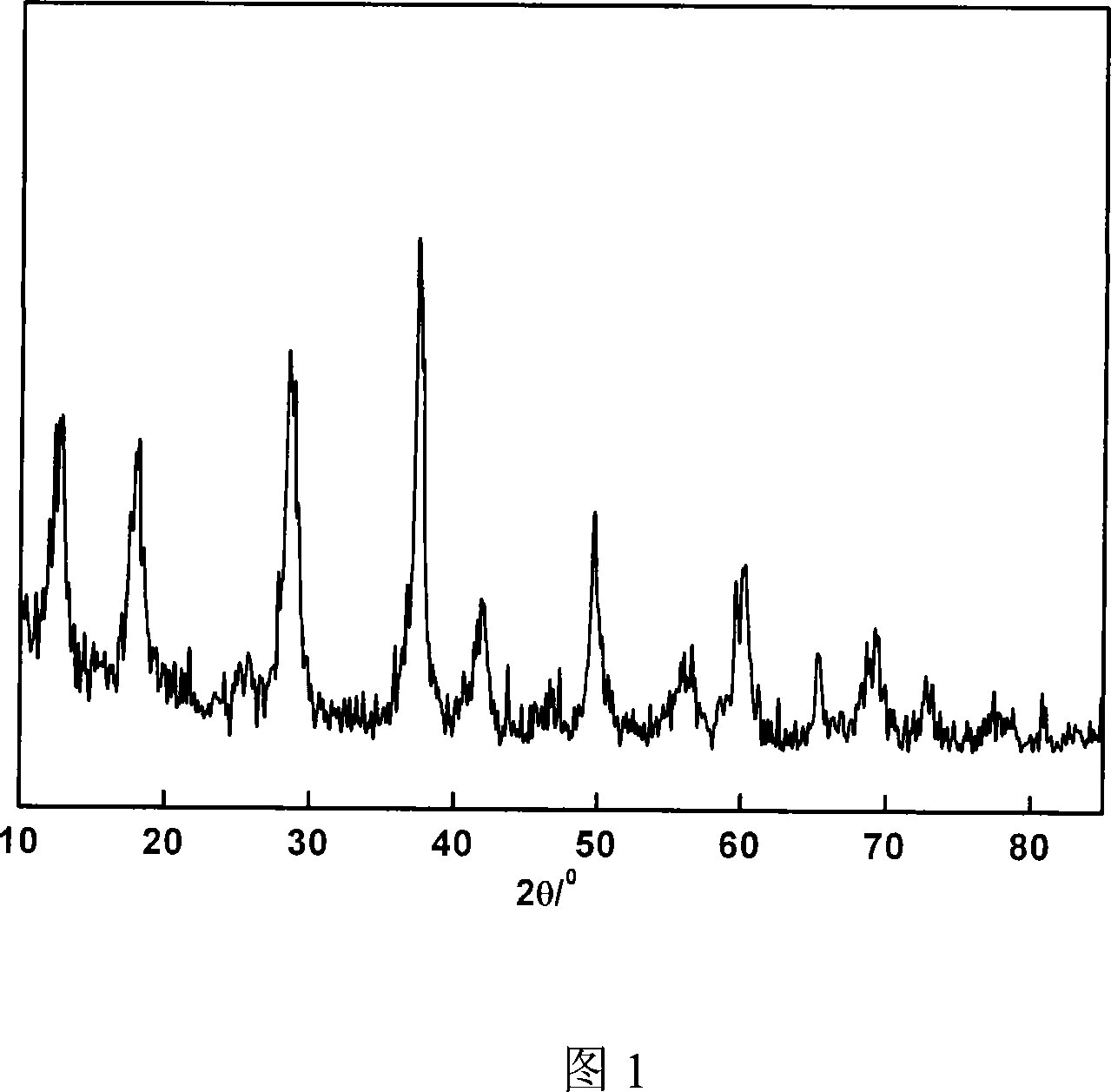

Image

Examples

Embodiment 1

[0009] Potassium permanganate and manganese sulfate are mixed into a uniform solution according to the molar ratio of 0.76, and concentrated nitric acid is added to adjust the pH value to less than 1, and the solution is transferred to an ultrasonic water bath at 75°C, with an ultrasonic frequency of 40KHz, an ultrasonic power of 120w, and ultrasonic reaction for 12 hours Then filter, wash with deionized water and ethanol repeatedly, and dry at 90°C for 12 hours to obtain the OMS-2 material.

Embodiment 2

[0011] Potassium permanganate and manganese sulfate are mixed into a uniform solution according to the molar ratio of 0.76. Add concentrated nitric acid to adjust the pH value to less than 1. The solution is transferred to an ultrasonic water bath at 75°C. Then filter, wash with deionized water and ethanol repeatedly, and dry at 90°C for 12 hours to obtain the OMS-2 material.

Embodiment 3

[0013] Potassium permanganate and manganese sulfate are mixed into a uniform solution according to the molar ratio of 0.76, and concentrated nitric acid is added to adjust the pH value to less than 1, and the solution is transferred to an ultrasonic water bath at 70°C, with an ultrasonic frequency of 60KHz, an ultrasonic power of 120w, and ultrasonic reaction for 4 hours Then filter, wash with deionized water and ethanol repeatedly, and dry at 90°C for 12 hours to obtain the OMS-2 material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com