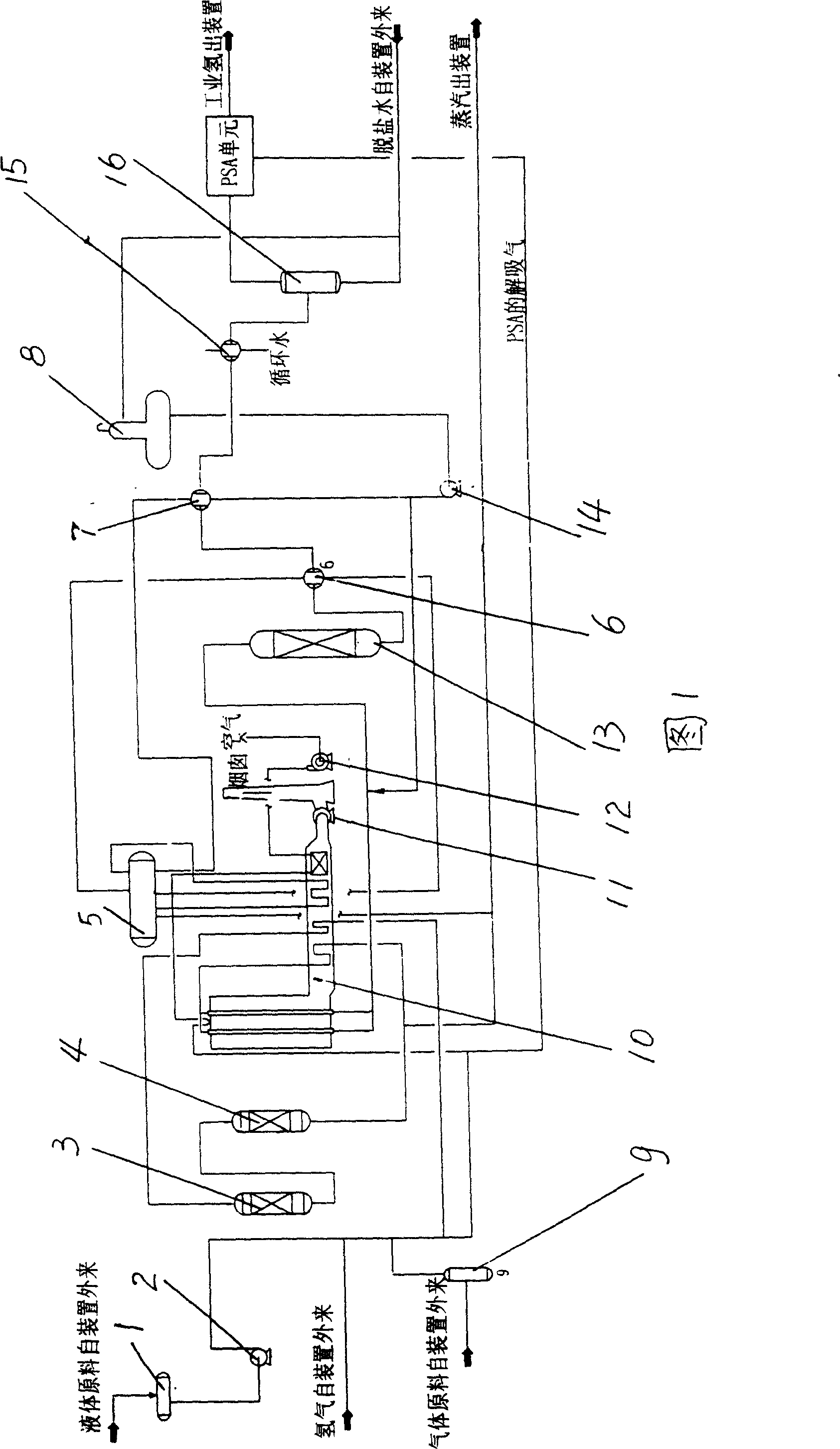

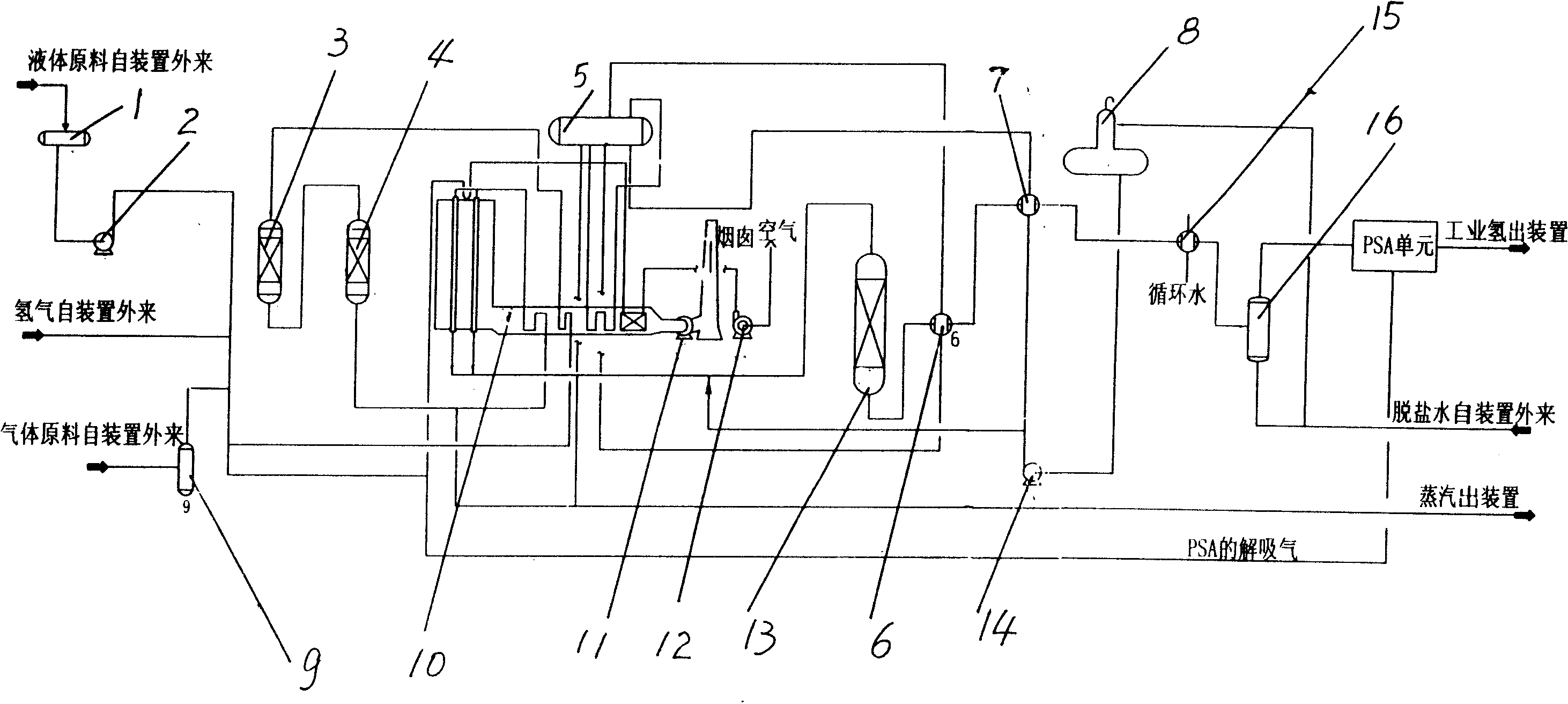

Minitype light hydrocarbon steam reforming hydrogen manufacturing technique

A process method and steam technology are applied in the complete process equipment and technical field of small-scale light hydrocarbon steam reforming for hydrogen production, which can solve the problems of high investment and hydrogen cost, influence of hydrogen cost, etc., and achieve low production energy consumption and low raw material consumption. , the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The light hydrocarbons described in the present invention are light naphtha, chemical light oil, natural gas, liquefied petroleum gas, oil field condensate oil, biogas, hydrogenated dry gas produced by refineries, coking dry gas, catalytic dry gas, etc., generally The total sulfur content in light hydrocarbons is required to be less than 500ppm.

[0013] The raw material refining process of the present invention adopts a raw material heating furnace or various waste heat heating, hydrogenation reactors and zinc oxide desulfurization reactors. The reactor is a fixed bed reactor, and the reaction temperature is 350-380°C.

[0014] The reformer described in the present invention, its furnace type is a square box furnace, or a cylindrical furnace; the combustion mode of the burner is top burning, bottom burning or side burning; the fuel is the analytical gas of the PSA unit, and the insufficient part of the fuel is supplemented by other fuels A number of furnace tubes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com