Method of amylorrhexis for preparing starchiness power glue

An energy gel and starch-based technology, applied in the field of starch deep processing, can solve the problems of slow energy supply, inability to be used as an energy source, and low energy release efficiency, and achieve the effect of less equipment, low product price, and rapid replenishment of physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the viscosity stability comparison of homogeneous and unhomogeneous starch hydrolyzate

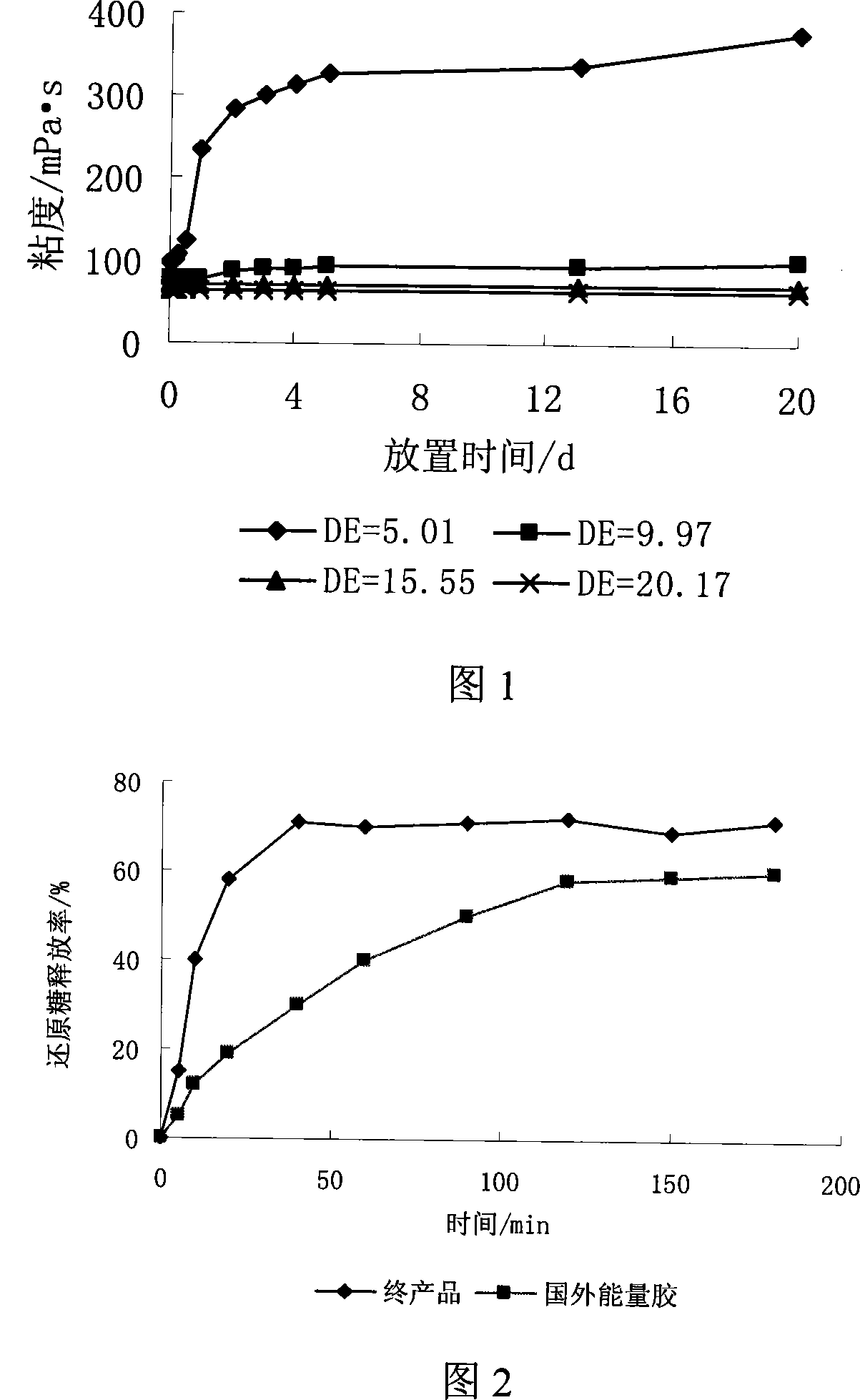

[0025] The starch slurry with a solid content of 50% is used with a high temperature resistant α-amylase at a pH value of 6.2 and at 92°C, using the amount of high temperature resistant α-amylase and the reaction time to control the DE value to 5, 10, 15 , 20 hydrolyzate, hydrolyzate with different DE values showed different viscosity stability, such as figure 1 shown. The hydrolyzate with a DE value of 15 is concentrated to a solid concentration of 55%, and the viscosity stability after homogenization under different pressures is shown in Table 1. From figure 1 As can be seen from Table 1, the product obtained after the hydrolyzate with a DE value of 15 is homogenized under a pressure of 30-50 MPa has basically no change in viscosity within 5 months and has good stability.

[0026] Table 1 Viscosity stability of starch hydrolyzed products under different homogene...

Embodiment 2

[0028] Embodiment 2: Experiment of anti-fatigue effect of starchy energy gel

[0029] Thirty healthy male NIH mice were randomly divided into exercise control group, soluble starch group, and high-, medium-, and low-dose groups of starch-based energy gels according to body weight. They had free access to drinking water and food, and administered the dosage according to Table 2. After the rats were gavaged for 30 minutes, the mice were placed to swim in a swimming tank with a water depth of about 30 cm and a water temperature of 25°C ± 0.5°C. The root of the tail of the rats was loaded with 5% of the body weight of lead skin, and the rats were driven away and kept swimming until the mice were completely submerged in the water for 10 seconds. Coming out of the water is defined as drowning. The time from the start of swimming to the death of the mice was recorded as the swimming time (min) of the mice.

[0030] Table 2 Dosage for animal experiments

[0031]

[0032] N...

Embodiment 3

[0037] Embodiment 3: Determination of osmotic pressure of starch energy gel

[0038] The osmotic pressure range of human blood is 280-320 mOsm / L, which is equivalent to 0.9% sodium chloride solution or 5% glucose solution.

[0039] The starch energy gel of the present invention is in a colloidal state, and the solid content is about 45%-60%. Therefore, the starch hydrolyzates with different DE values are concentrated to 55%, and the osmotic pressure value is measured with a freezing point osmometer. The result as follows:

[0040] Table 4 Osmotic pressure values of starch hydrolyzates with different DE values

[0041] DE value

5.01

9.97

12.31

15.82

20.18

Osmotic pressure value / Mosm

-

201

245

305

384

[0042] Note: "-" indicates that the osmotic pressure value is low and exceeds the measurement range of the osmometer.

[0043] It can be seen from Table 4 that the osmotic pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com