Mixture of new capable of degradation totally bone inside fixed polymer and cross-linking method

A cross-linking method and technology of cross-linking agent, which are applied in medical science, prosthesis, surgery, etc., can solve the problems of high cost and low mechanical strength, and achieve the effect of low production cost and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Synthesis of unsaturated polyester amide

[0041] Under nitrogen protection, add 0.024mol (3.59g) of phthalic anhydride, 0.046mol (3.49g) of propylene glycol, and 0.049mol (5.09g) of neopentyl glycol into a three-necked flask with a magnetic stirrer and an oil-water separator, and stir under strong magnetic force. Raise the temperature of the system to 160°C for 1 hour, cool to 120°C and add 0.076mol (7.42g) of maleic anhydride and 0.0125mol (0.937g) of glycine to react for 1 hour, then raise the temperature to 180°C for 1 hour, then Polycondensation reaction at 195°C for 4 hours, then lower the reaction temperature to 120°C, add 10% cyclohexanol to react for 1 hour, raise the temperature to 160°C for 1 hour, then raise the temperature to 180°C for 1 hour. After the temperature drops to 100°C, it is taken out, and a light brown transparent viscous unsaturated polyester amide is obtained after cooling.

Embodiment 2

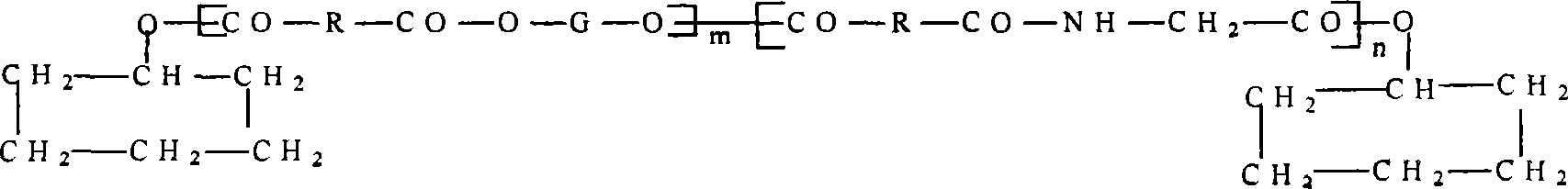

[0042] Example 2: Crosslinking of unsaturated polyester amides

[0043] Dissolve 0.06g of benzoyl peroxide in 2g of vinyl acetate, add vinyl acetate in which benzoyl peroxide has been dissolved in 8g of synthesized unsaturated polyester amide and stir evenly, then add 0.002g of N, N - Dimethylaniline is used as an accelerator, fully miscible and then poured into the pre-prepared polytetrafluoroethylene mold for cross-linking at room temperature. After a certain period of time, take out the cross-linked sample and heat-treat it in an oven at 100°C for 1 hour, then lower the temperature Heat treatment at 195°C for 22 hours.

Embodiment 3

[0044] Example 3: Crosslinking of unsaturated polyester amides

[0045] Dissolve 0.06g of benzoyl peroxide in 3g of vinyl acetate, add benzoyl peroxide-dissolved vinyl acetate into 7g of synthetic unsaturated polyester amide and stir evenly, then add 0.002g of N, N - Dimethylaniline is used as an accelerator, fully miscible and then poured into the pre-prepared polytetrafluoroethylene mold for cross-linking at room temperature. After a certain period of time, take out the cross-linked sample and heat-treat it in an oven at 100°C for 1 hour, then lower the temperature Heat treatment at 195°C for 22 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com