Total-fibroin albumen composite material and preparation method thereof

A technology of silk fibroin and composite materials, which is applied in the fields of textile fiber processing and protein chemistry, and can solve problems such as the inability to obtain high-concentration silk fibroin aqueous solution, the final degradation and recycling of unfavorable materials, and the limited size of silk fibroin membrane materials. , to achieve the effects of easy cell adhesion, improved interfacial compatibility, and easy biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

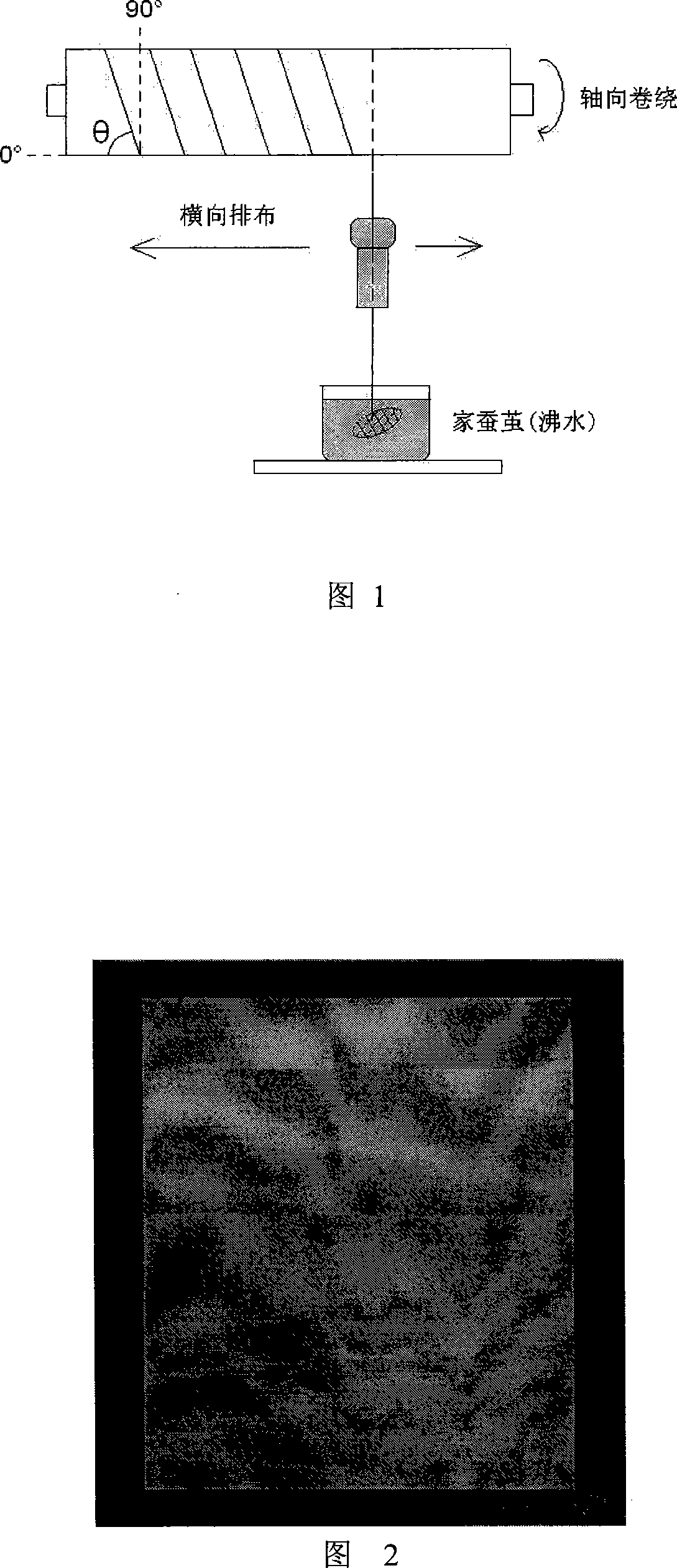

[0019] Example 1: Silkworm cocoons arranged in one direction were treated with 0.5% sodium bicarbonate solution at 98° C. for 60 minutes. After rinsing with deionized water, it was flow-dried to constant weight at room temperature, and the mass of the silk fiber was weighed. The degummed silk was treated with 6mol / L lithium bromide solution for 10 minutes, and then quickly washed with water to completely remove the residual lithium bromide on the surface. Then, under the condition of 4°C, with the regenerated silk fibroin solution with a concentration of 15.6% as the matrix, soak the pretreated silk for 24 hours, defoam and let it stand, and finally cast it into a film at room temperature. Control the content of silk fiber in the final composite material to be 25%. The tensile strength of the obtained composite material extending along the long axis of the fiber is 151±5MPa, the elongation at break is 27.1±1.4%, and the Young's modulus is 2.8±0.1GPa.

Embodiment 2

[0020] Example 2: The unidirectionally arranged silkworm cocoons were treated with 0.5% sodium carbonate solution at 105° C. for 30 minutes and repeated twice. After rinsing with deionized water, it was flow-dried to constant weight at room temperature, and the mass of the silk fiber was weighed. The degummed silk was treated with 8mol / L lithium bromide solution for 1 hour, and then quickly washed with water to completely remove the residual lithium bromide on the surface. Then, under the condition of 4°C, with the regenerated silk fibroin solution with a concentration of 13.3% as the matrix, the pretreated silk was soaked for 24 hours, defoamed and left standing, and finally casted at room temperature to form a film. Control the content of silk fiber in the final composite material to be 10%. The tensile strength of the obtained composite material along the long axis of the fiber is 64±4MPa, the elongation at break is 6.4±1.4%, and the Young's modulus is 2.9±0.2GPa.

Embodiment 3

[0021] Example 3: The unidirectionally arranged silk cocoons were treated with 0.5% sodium bicarbonate solution at 100° C. for 60 minutes. After rinsing with deionized water, it was flow-dried to constant weight at room temperature, and the mass of the silk fiber was weighed. The degummed silk was treated with 4mol / L guanidine hydrochloride solution for 30 minutes, and then quickly washed with water to completely remove residual guanidine hydrochloride on the surface. Then, under the condition of 4°C, with the regenerated silk fibroin solution with a concentration of 14.6% as the matrix, the pretreated silk was soaked for 24 hours, defoamed and left standing, and finally casted at room temperature to form a film. Control the content of silk fiber in the final composite material to be 20%. The tensile strength of the obtained composite material along the long axis of the fiber is 137±8MPa, the elongation at break is 21.7±2.4%, and the Young's modulus is 2.7±0.2GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com