Method for preparing tin oxide nanocrystalline coated by organic ligand

A technology of tin oxide nanocrystals and organic ligands, applied in the direction of tin oxide, etc., can solve the problems of difficult dispersion of nanocrystals, high reaction temperature, and difficulty in controlling the size and shape of nanocrystals. The method is simple and easy, and the reaction conditions are mild , The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

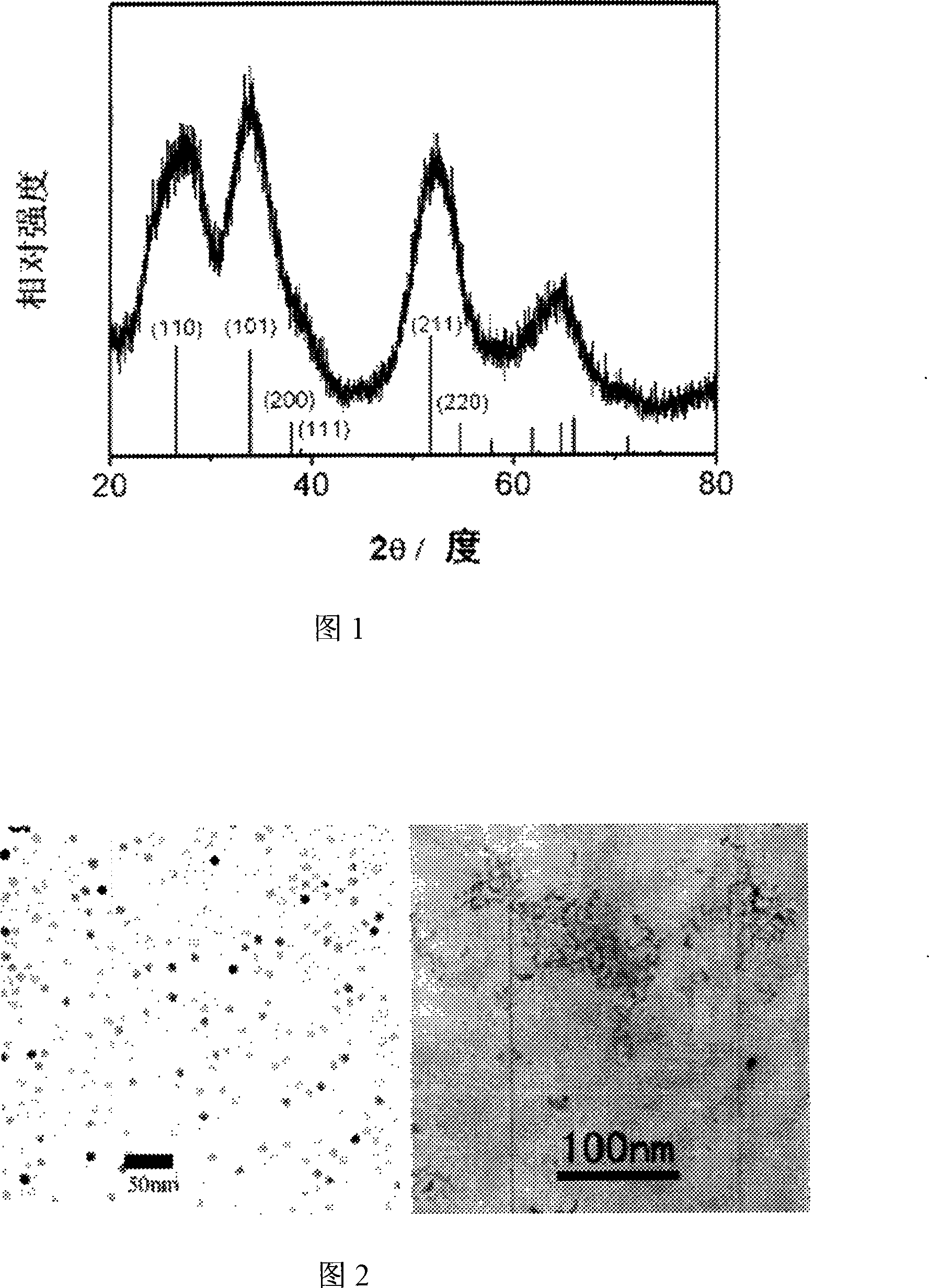

[0021] Example 1: Preparation of SnO nanocrystals coated with spherical organic ligands:

[0022] Add 0.15mmol of tin source, 0.5g of myristic acid and 25ml of toluene to the polytetrafluoroethylene lining of a 30ml autoclave, then add 2ml of an aqueous solution containing 0.2ml of n-butylamine to the system, seal the autoclave, and put Heat in the furnace at 120°C for 1h (the pressure is kept at 1-10MPa), and after cooling, white nanocrystals are formed in the oil phase. Its particle size is about 2nm. Can be dispersed in non-polar organic solvents such as toluene or chloroform. The nanocrystal precipitate obtained by centrifuging the above oil phase was dissolved in 15 ml of pyridine, and heated to reflux at 60° C. for 6 hours to obtain pyridine-coated tin oxide nanocrystals.

Embodiment 2

[0023] Example 2: Preparation of tin oxide nanocrystals coated with branched organic ligands:

[0024] Add 0.05mmol of tin source, 1ml of oleic acid and 20ml of toluene to the PTFE lining of a 30ml autoclave, then add 5ml of an aqueous solution containing 0.5ml of tert-butylamine into the system, seal the autoclave and put it in a furnace to heat at 180°C 12h (the pressure is maintained at 1-10MPa), white nanocrystals are formed in the oil phase after cooling. The nanocrystals can be dispersed in non-polar organic solvents such as toluene or chloroform. The branch width is about 1.5nm.

Embodiment 3

[0025] Example 3: Preparation of tin oxide nanocrystals coated with branched organic ligands:

[0026] Add 0.02mmol tin source, 0.5g oleylamine and 10ml toluene to the polytetrafluoroethylene lining of a 30ml autoclave, then add 2ml of an aqueous solution containing 0.0012g urea to the system, seal the autoclave and put it into the furnace at 180 Heating at ℃ for 6 hours (the pressure is maintained at 1-10MPa), and white nanocrystals are formed in the oil phase after cooling. Its shape is branch-like. The nanocrystal precipitate obtained by centrifuging the above oil phase was dissolved in 10 ml of pyridine, and heated to reflux at 60° C. for 6 hours to obtain pyridine-coated tin oxide nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com