Radio frequency magnetron sputtering method to prepare superhard TiB2/TiAIN nano multilayer film

A radio frequency magnetron sputtering, nano-multilayer technology, applied in the direction of sputtering coating, coating, layered products, etc., can solve the problems of surface strengthening failure, brittle cracking, low brittleness, etc., and achieve the effect of enhancing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Synthesis of TiB at room temperature 2 / TiAlN nano multilayer film:

[0031] (1) Before the experiment, the Si wafers were ultrasonically cleaned with anhydrous alcohol and acetone for 10 minutes, and after drying, they were placed in the ion beam assisted deposition coating chamber and bombarded and cleaned with Ar ion beams for at least 15 minutes for all samples.

[0032] (2) Vacuum the chamber so that the background vacuum in the chamber is 3×10 -4 Pa to 1×10 -4 Pa between.

[0033] (3) Use a mass flow meter to control the Ar intake flow to keep it at 4-60sccm, adjust the gate valve to keep the air pressure in the vacuum chamber at 2-3Pa, gradually increase the radio frequency voltage to make the two targets glow, and TiB 2 The RF power of TiAl is set at 60-100W, and the RF power of TiAl is set at 60-100W (adjustable).

[0034] (4) On the premise of not adding substrate bias voltage, first deposit metal Ti with a thickness of about 40-60 nm on the Si substrate t...

PUM

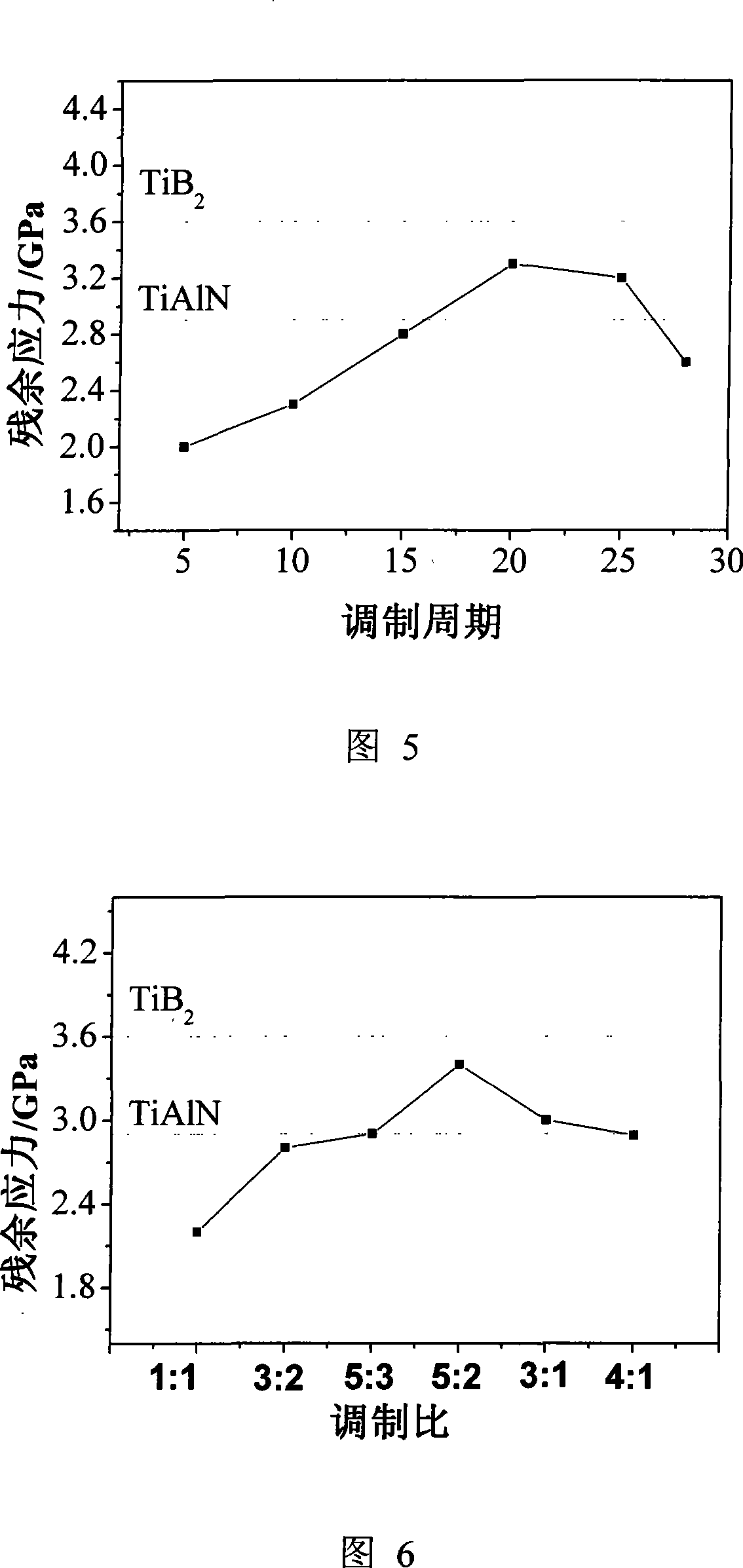

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com