Method for preparing immobilized enzyme biological catalyst

A biocatalyst, immobilized enzyme technology, applied in the direction of immobilization on/in an organic carrier, can solve the problems of difficult to control the distribution of pore size, easy inactivation of water-soluble enzymes, limited mass transfer, etc., to achieve good enzymes The effect of dispersibility, high recovery rate of enzyme activity, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

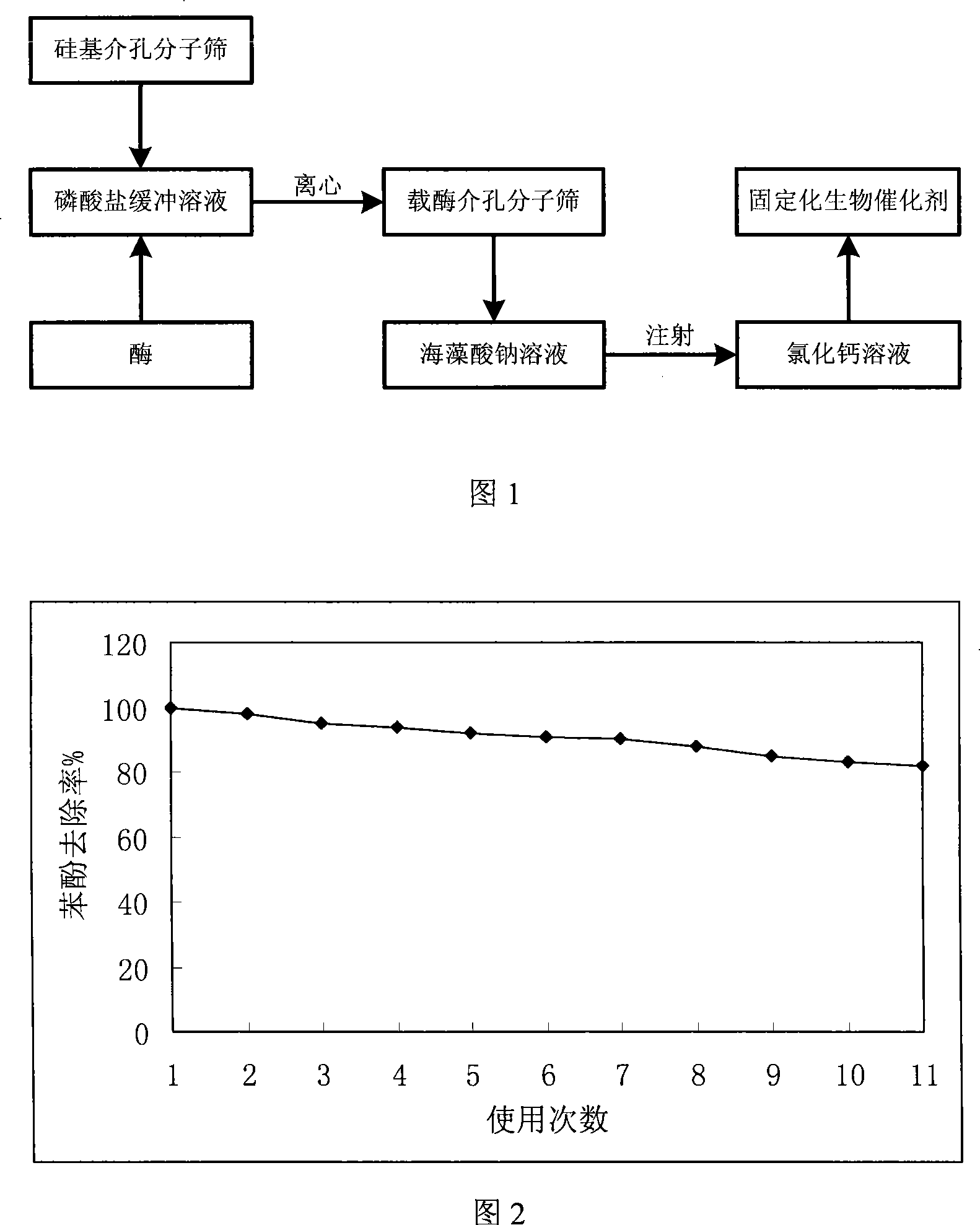

[0015] See the process flow diagram of Figure 1. First, the silicon-based mesoporous molecular sieve MCM-41 carrier was prepared at room temperature. Hexadecyl ammonium bromide was used as template, and tetraethyl orthosilicate was used as silicon source. Earlier the CTAB of 0.75g was dissolved in the deionized water of 15g, then the dehydrated alcohol (C 2 h 5 OH) and 0.6g pore expander TMB were added to the surfactant solution. Stir the solution for 15 minutes, then add 1.4 g of tetraethyl orthosilicate (TEOS), and stir at room temperature for 2 hours, then filter the sample solution with suction, wash with water, and dry, and the resulting white powder is the raw material with template. MCM-41, and finally the original MCM-41 is calcined. The calcination temperature is 550° C., and kept at this temperature for 6 hours, and then the temperature is naturally lowered. The calcined powder is MCM-41 with channels. Add 0.25g of MCM-41 to 10ml of phosphate buffer solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com