Method for magnetic separation of concentration oxygen and multifunctional device thereof

A technology for magnetic separation and enrichment of oxygen, which is applied in oxygen preparation, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of expensive chemical raw materials, low performance-price ratio, application limitations, etc., and achieve improved performance Compared with the price, it is beneficial to recover the investment and improve the value of the investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

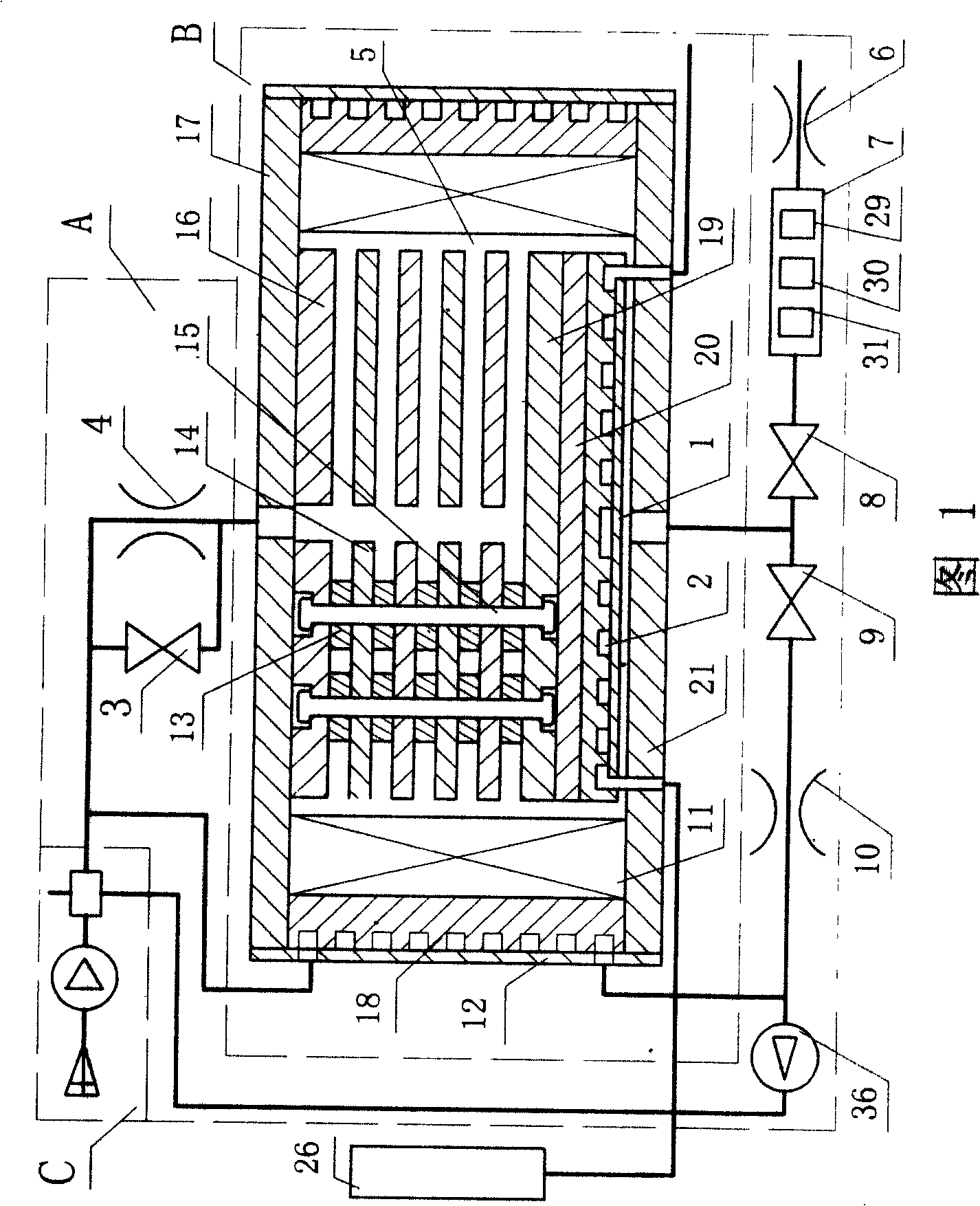

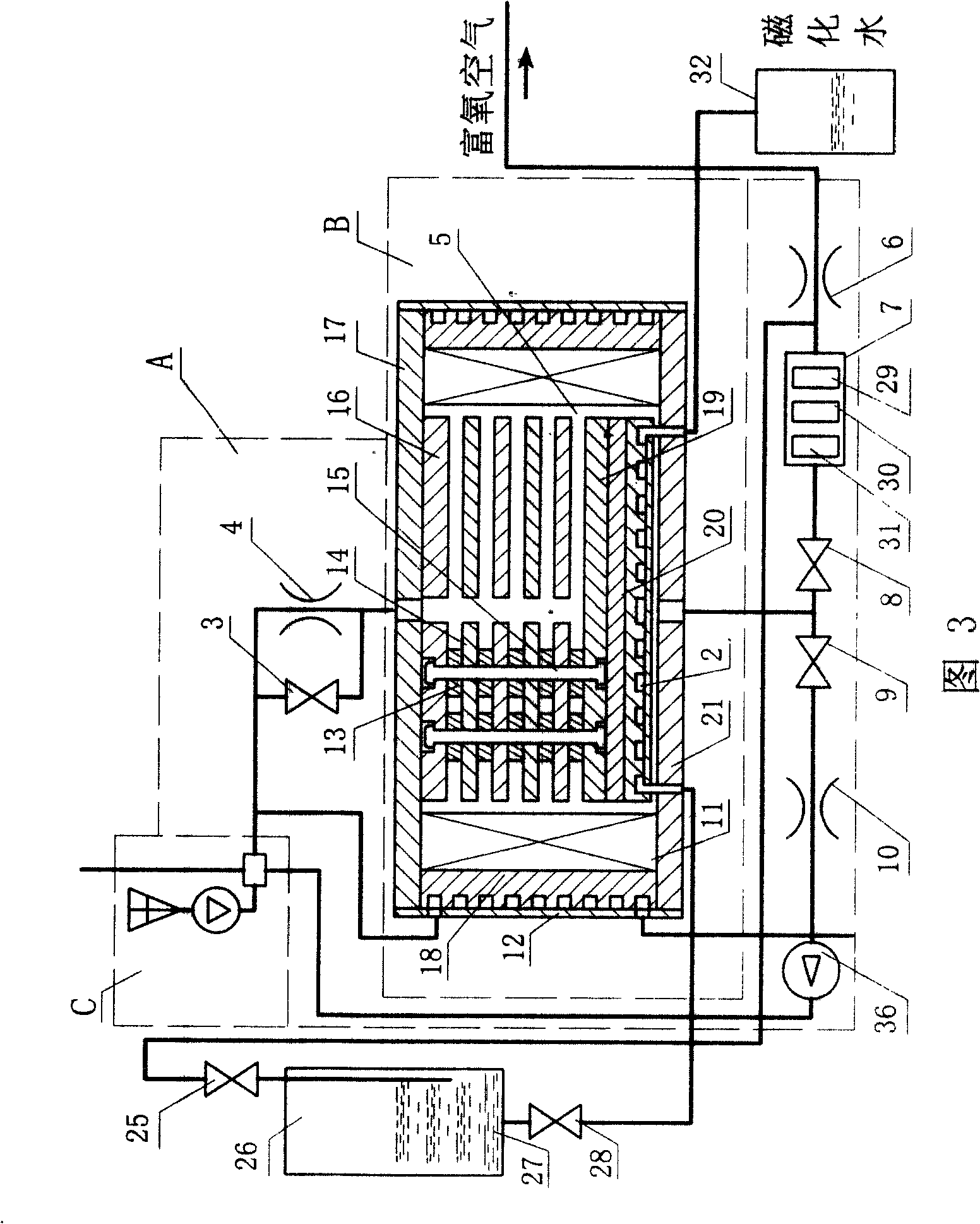

[0112] Figure 1 is a schematic diagram of the present invention.

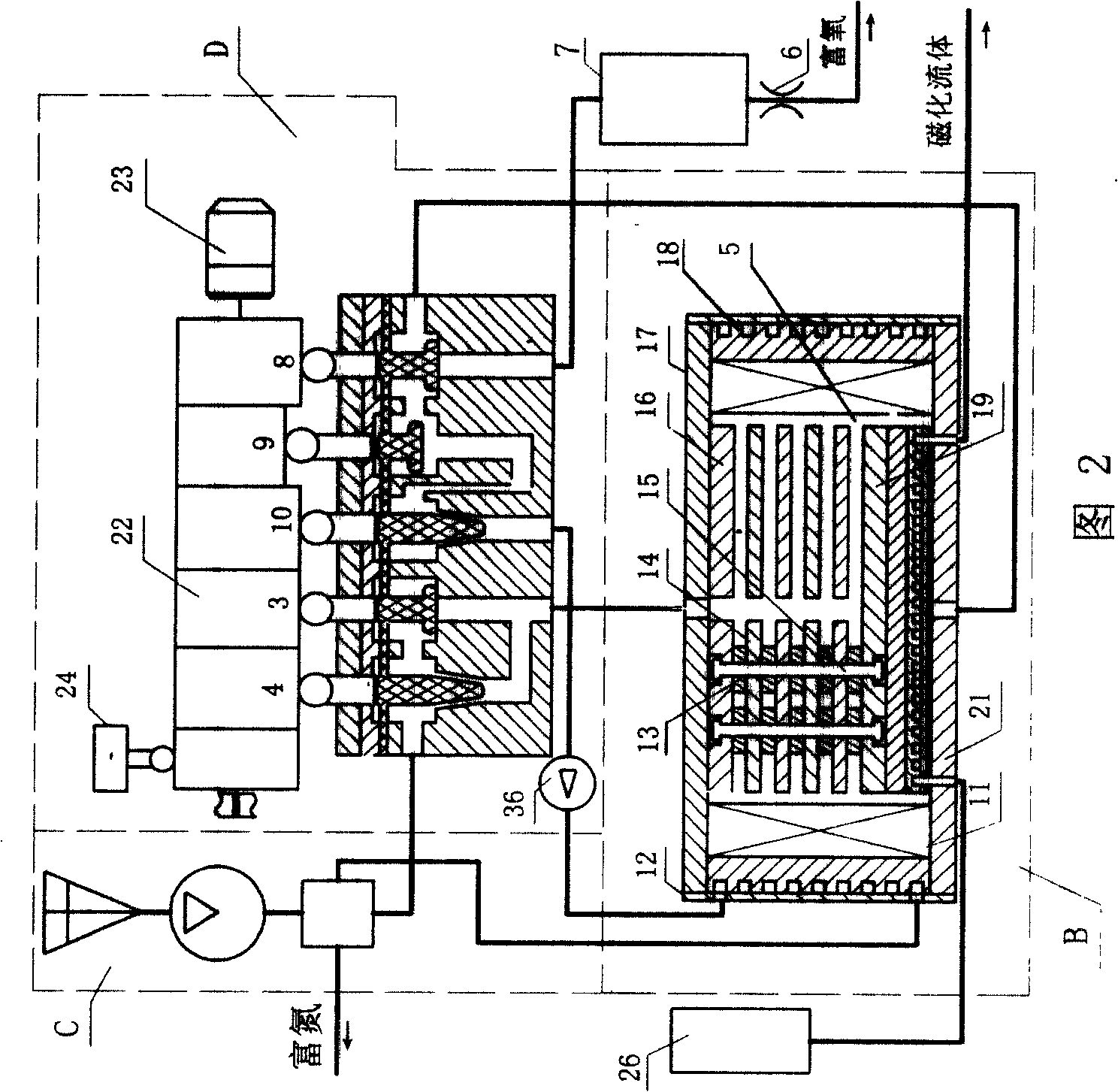

[0113] Fig. 2 is a schematic structural diagram of the present invention, the driver 23 and the cam 22 of the present invention control the cycle of two working stages.

[0114] In Figure 1, the cycle of two working stages.

[0115] The first paragraph, the process of turning on the electromagnetic, the formation of rich oxygen and the exhaustion of nitrogen-rich and carbon dioxide gases:

[0116] The air passes through the preprocessor C to form air with pressure and enters the second valve 4. The second valve 4 controls the pressure and flow of the air and enters the separation space 5. The oxygen molecules in the air are affected by the magnetic field force, and the movement is hindered and changed. slow, is adsorbed on the surface of the magnetic medium 14, and the magnetic susceptibility of nitrogen and carbon dioxide gas is small, and the magnetic force effect is much smaller. Exhausted from the nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com