Laser etching and trench digging method of semiconductor chip

A laser etching and semiconductor technology, applied in semiconductor/solid-state device manufacturing, laser welding equipment, electrical components, etc., can solve the problems of deposition on the side of the engraved pattern, pattern deformation, poor selectivity, etc., and achieve good consistency , small thermal effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

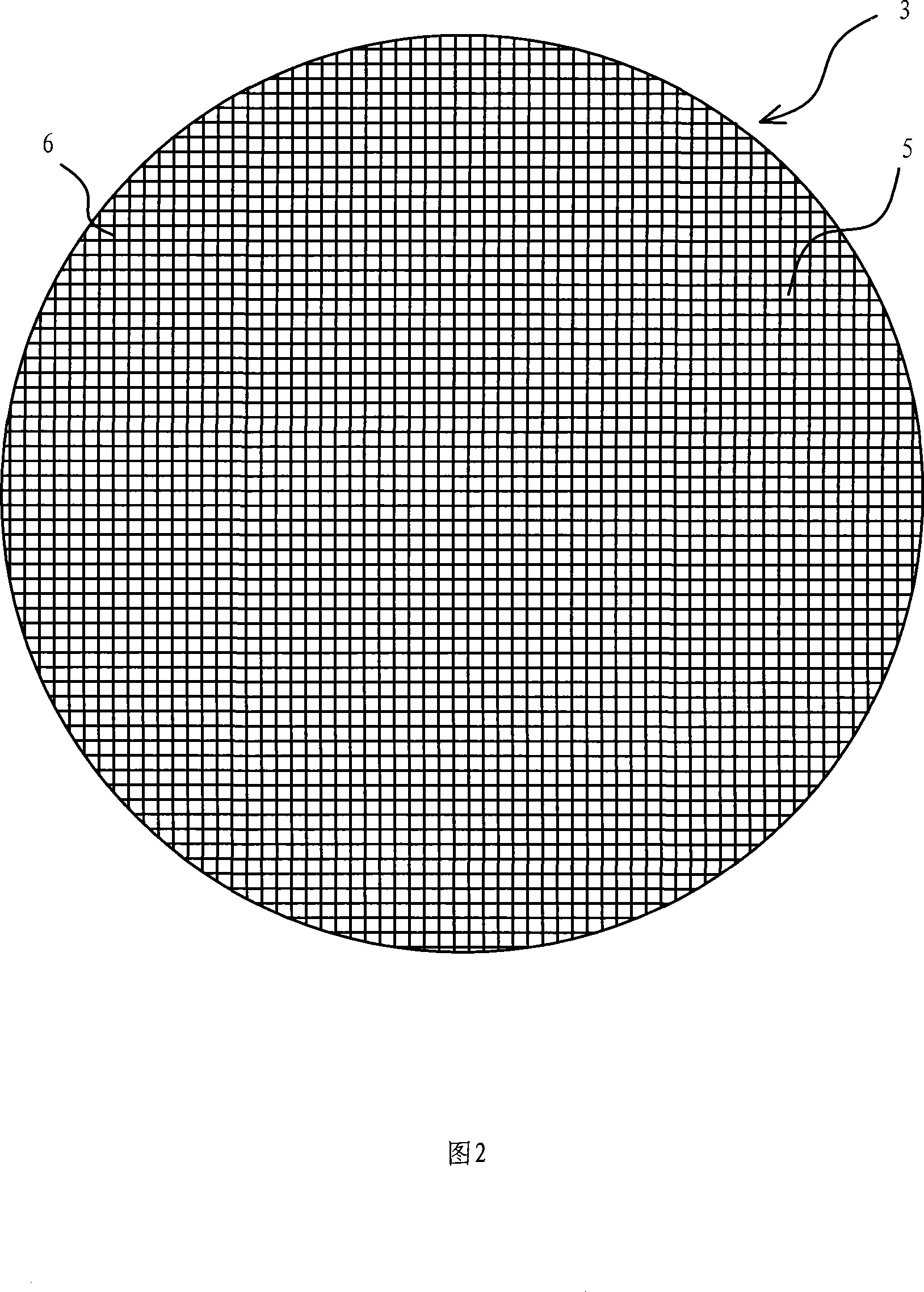

[0038] Embodiment: A semiconductor wafer laser etching trenching method, which consists of two parts: laser etching to form a trench and post-processing.

[0039] As shown in Figure 2, laser etching forms the groove by fixing the semiconductor wafer 3 on the workbench 4 through the clamp, and utilizing the laser beam 2 emitted by the laser 1 to radiate the surface of the semiconductor wafer 3 vertically, along with the laser beam 1 and the semiconductor wafer 3 On the moving path, the laser beam 2 etches the material on the surface layer of the radiation area by melting and evaporating, thereby forming grooves on the surface of the semiconductor wafer 3 .

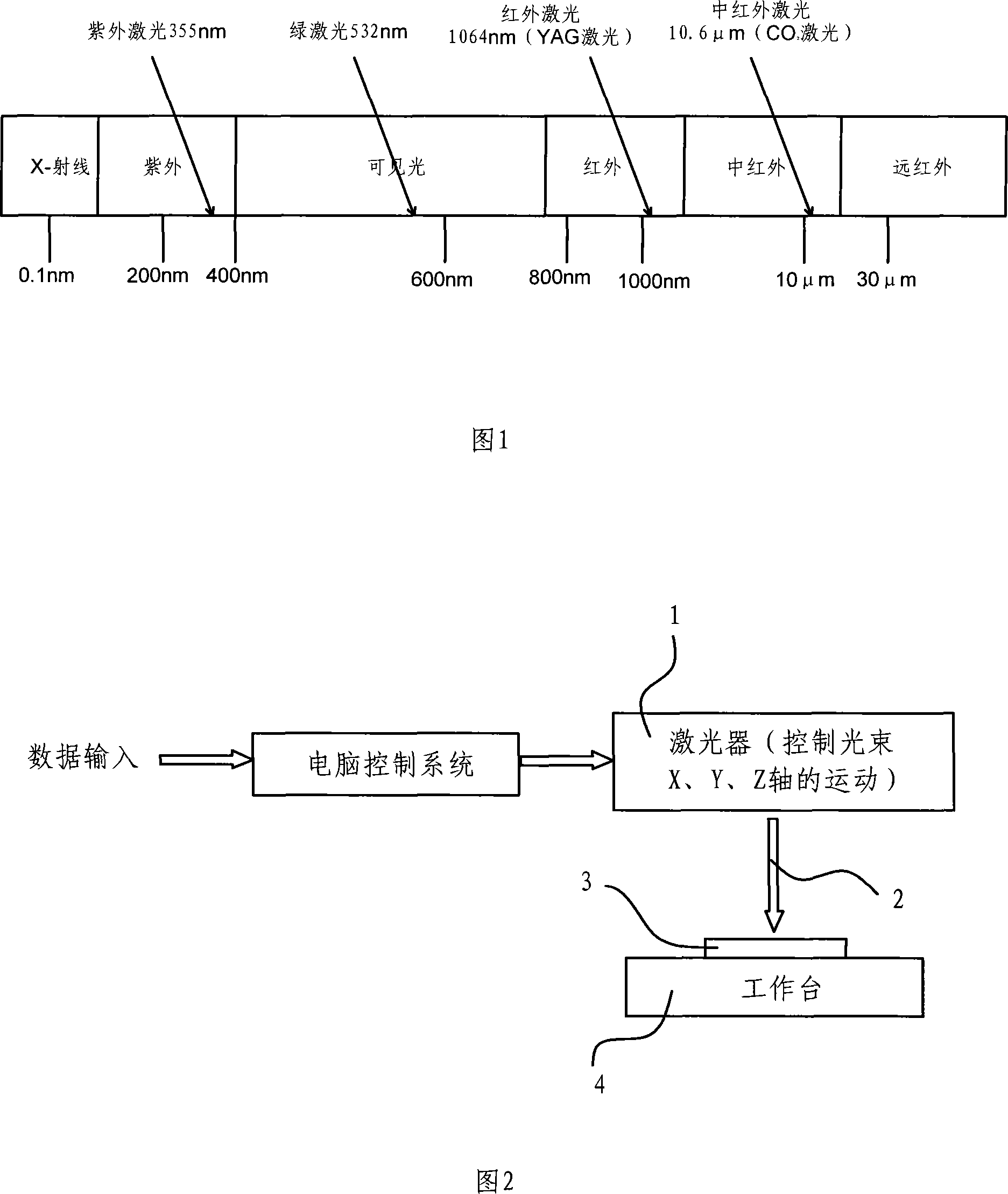

[0040] The laser beam 2 is an ultraviolet laser with a wavelength of 200-400 nanometers, as shown in Figure 1, this laser is a cold laser light source with a small thermal effect area, so it will not damage the semiconductor lattice outside the radiation area. In addition, the operating frequency of the laser beam 2 is sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com