Double-layer environment protection gas-phase rust-proofing film membrane and preparation method thereof

A gas-phase anti-rust and thin-film technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of polluting metal or metal products, reducing the anti-rust performance of the film, and failing to achieve anti-rust effects, etc. problem, to achieve the effect of good isolation or shielding, good anti-rust performance, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

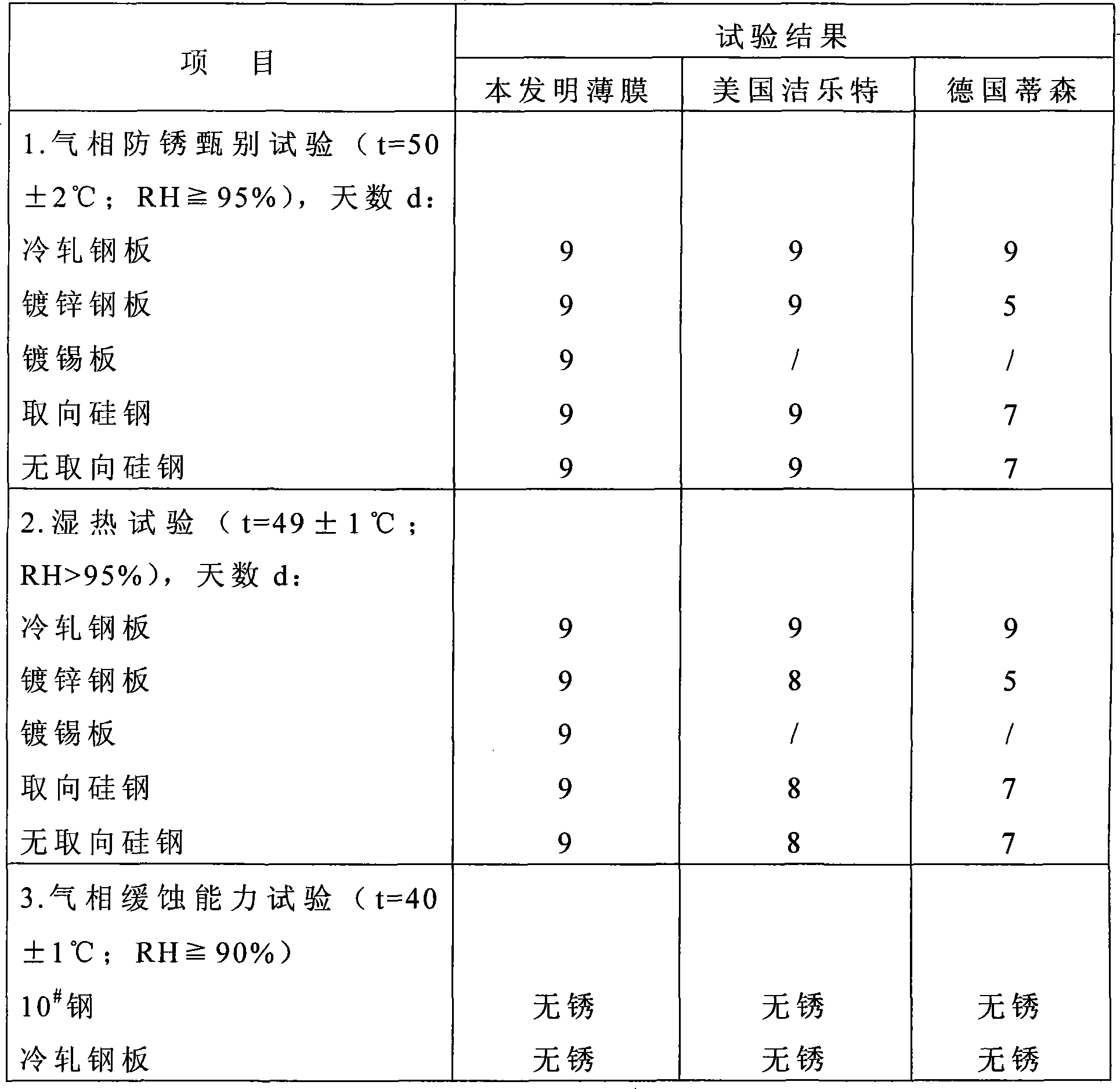

Examples

Embodiment 1

[0022] First, weigh 1kg of gas-phase corrosion inhibitor (VCI) raw material sodium tetraborate, 2kg of ammonium molybdate, 3kg of cyclohexylamine laurate, 0.3kg of polyethylene wax as a raw material for dispersing lubricant, and 2.5kg of EVA as a carrier plastic material. After mixing evenly, put it into a high-speed mixer and mix for 20 minutes. The friction heat generated by the high-speed mixer will make the EVA particles sticky, and the polyethylene wax will melt under the action of shear heat. The raw materials are naturally cooled, and then put into a granulator for granulation to obtain prepared additive granules.

[0023] Then, take the inner release layer plastic raw material LLDPE72kg and LDPE18kg, mix it with the prepared additive granules evenly, and put it into the inner layer extrusion barrel of the blow molding machine; simultaneously weigh the outer shielding layer plastic raw material LDPE31.2kg, Put it into the outer extrusion barrel of the blow molding machi...

Embodiment 2

[0026] First, weigh 2kg of gas phase corrosion inhibitor (VCI) raw material sodium tetraborate, 1kg of ammonium molybdate, 1.5kg of cyclohexylamine laurate, 0.2kg of polyethylene wax as a raw material for dispersing lubricant, and 2.0kg of EVA as a carrier plastic material. After the parts are mixed evenly, put them into the high-speed mixer and mix for 20 minutes. The frictional heat generated by the high-speed mixer will make the EVA particles sticky, and the polyethylene wax will melt under the action of shear heat. When the VCI is evenly adhered to the EVA The material is discharged, cooled naturally, and then put into a granulator for granulation to obtain prepared additive granules.

[0027] Then, take the inner release layer plastic raw material LLDPE64kg and LDPE16kg, mix it with the prepared additive granules evenly, and put it into the inner layer extrusion barrel of the blow molding machine; simultaneously weigh the outer shielding layer plastic raw material LDPE53.3...

Embodiment 3

[0030] First, weigh 1.5kg of gas phase corrosion inhibitor (VCI) raw material sodium tetraborate, 1.5kg of ammonium molybdate, 1.5kg of cyclohexylamine laurate, 0.3kg of polyethylene wax as raw material for dispersing lubricant, and 1.5kg of carrier plastic raw material EVA. After the components are mixed evenly, put them into the high-speed mixer and mix for 20 minutes. The frictional heat generated by the high-speed mixer will make the EVA particles sticky, and the polyethylene wax will melt under the action of shear heat. When the VCI evenly adheres to the EVA The material is discharged at the same time, and after natural cooling, it is put into the granulator for granulation to obtain the prepared additive granules.

[0031]Then, take the inner release layer plastic raw material LLDPE48kg and LDPE12kg, mix it with the prepared additive granules evenly, and put it into the inner layer extrusion barrel of the blow molding machine; simultaneously weigh the outer shielding laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com