Method and device for aging white spirit

A liquor aging technology, applied in the field of liquor aging, can solve problems such as safety doubts, difficulties in the aging process, damage, etc., and achieve the effects of promoting the occurrence of aging reactions, maintaining flavor characteristics, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

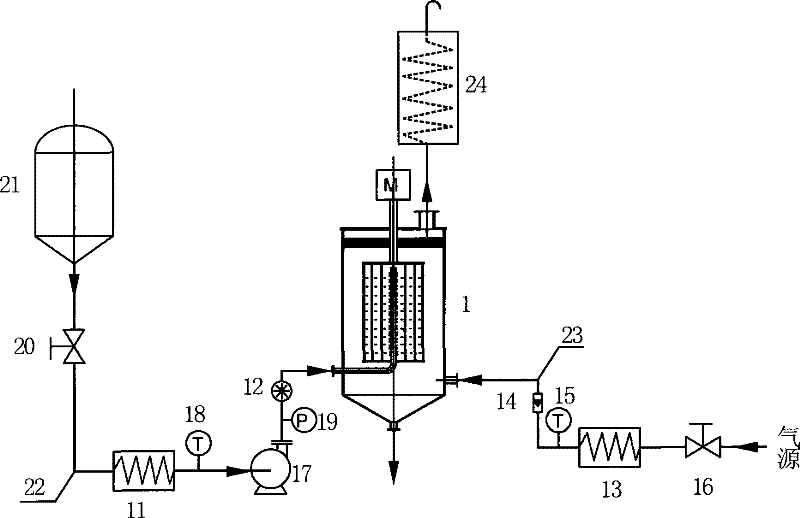

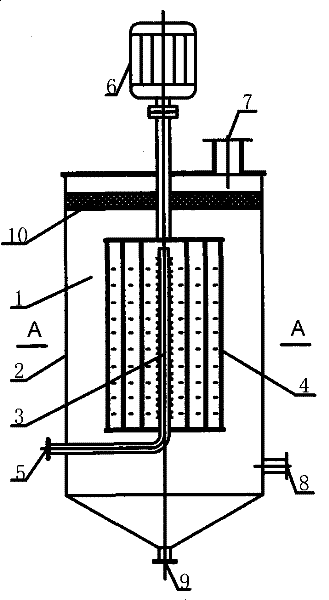

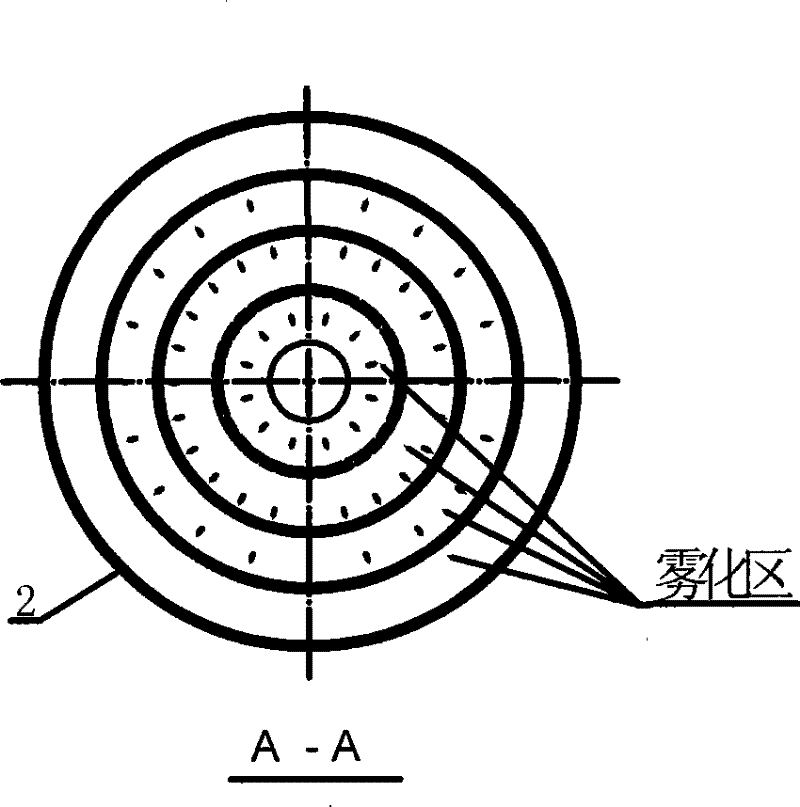

Embodiment 1

[0024] The liquor aging device adopts the device shown in the figure. The rotor of the high-gravity rotary bed is a wire mesh coated with ceramics, and the oxidizing gas is oxygen to treat the newly produced Fenjiu. Oxygen passes through the gas temperature control device, the inlet temperature is controlled between 45-50°C, and the flow rate is controlled at 2000L / m 3 / h; the wine liquid passes through the liquid temperature control device, the inlet temperature is controlled between 55-60 °C, and the flow rate is controlled at 1800-2000L / m 3Between / h; the speed of the motor is 1800rpm; the condenser is cooled with tap water. The wine liquid after treatment, wine loss is 0.4% (V / V), taste evaluation is better than the liquor of more than 2 years of natural storage, the relative percentage content of some trace components and the taste evaluation results of gas chromatography analysis are shown in Table 1 and Table 1. 2.

Embodiment 2

[0026] Air is used as the oxidizing gas, and the flow rate is controlled at 2500-3000L / m 3 Between / h, others are with embodiment 1. The wine liquid after treatment, wine loss is 0.45% (V / V), taste evaluation is better than the liquor of more than 2 years of natural storage, the relative percentage content of some trace components and taste evaluation results of gas chromatographic analysis are shown in Table 1 and Table 1. 2.

Embodiment 3

[0028] Ozone is used as the oxidizing gas, and the flow rate is controlled at 900-950L / m 3 Between / h, others are with embodiment 1. The wine liquid after treatment, wine loss is 0.3% (V / V), taste evaluation is better than the liquor of more than half a year of natural storage, the relative percentage content of some trace components and taste evaluation results of gas chromatography analysis are shown in Table 1 and Table 2 .

[0029] The relative percentage content of some trace components analyzed by gas chromatography in table 1 *

[0030]

[0031] n-propanol

3.8104

2.6988

2.6324

4.5979

4.3319

4.5563

4.7382

3.6268

3.7692

3.7546

5.4115

4.0531

4.2787

4.5214

10.7713

12.1913

14.6698

16.9677

13.2703

14.2846

14.3579

0.1521

0.1619

0.2067

0.2399

0.2293

0.2152

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com