Metoprolol salt oral administration impulse pellet preparation

A technology for pulsed pellets and preparations, which is applied in the field of metoprolol salt oral pulsed pellet preparations and metoprolol salt oral preparations, can solve problems such as difficulty in taking medicine by patients, achieve simple preparation process and improve compliance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

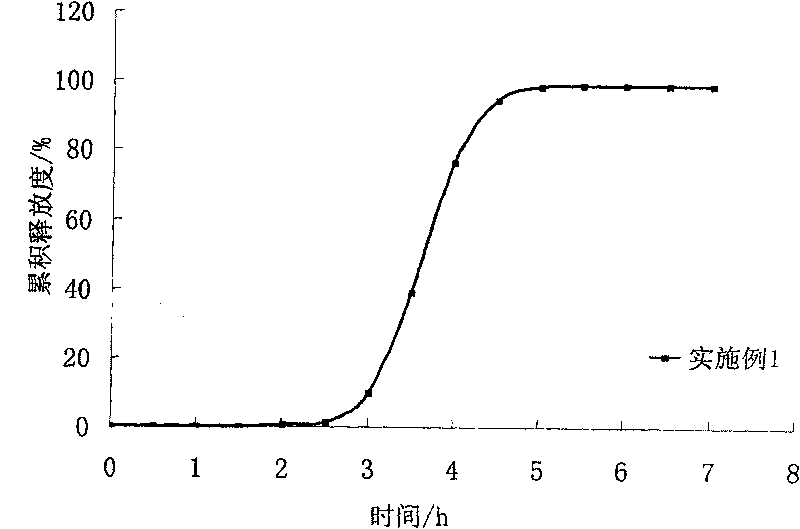

Embodiment 1

[0034] Prescription of quick-release pill core containing the main drug:

[0035] Starch sucrose blank core 400g

[0036] Metoprolol Tartrate 100g

[0037] 95% ethanol 1kg

[0038] Preparation process: dissolve metoprolol tartrate in 95% ethanol, apply fluidized bed coating, temperature 32±1°C, flow rate 8mL / min, wrap metoprolol tartrate on the blank pellet core, and obtain The main drug is the immediate-release pellet core. The average cumulative dissolution rate in 45 minutes was 93%.

[0039] Alkaline layer prescription: sodium bicarbonate 10% (w / v), add water to 100%.

[0040] Preparation process: Dissolve sodium bicarbonate in water, apply fluidized bed coating, temperature 50±1°C, flow rate 3mL / min, wrap sodium bicarbonate on the core of immediate-release pellets containing the main drug, and the weight of the coating increases by 20% , to prepare the ball core containing the basic layer.

[0041] Hysteresis layer prescription: w / v(%)

[0042] Polyacrylic resin II...

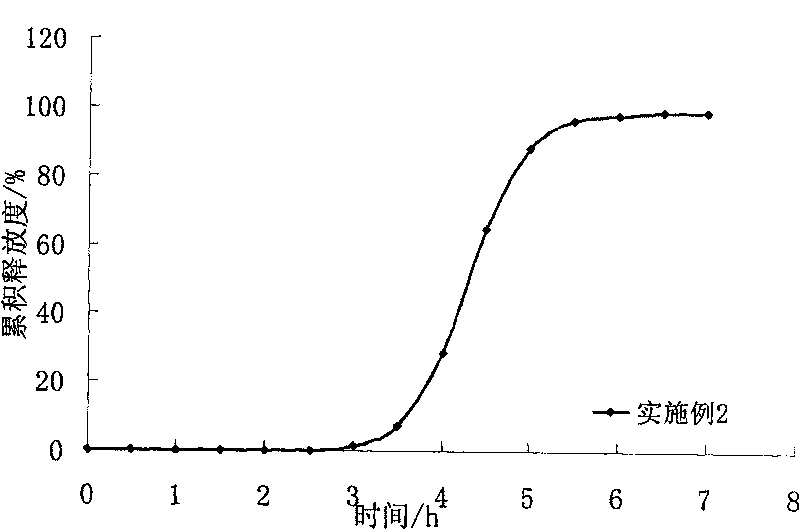

Embodiment 2

[0047] Prescription of quick-release pill core containing the main drug:

[0048] Starch sucrose blank core 600g

[0049] Metoprolol Succinate 100g

[0050] 95% ethanol 1kg

[0051] The coating process is the same as in Example 1. Contain the main drug quick-release pellet core. The average cumulative dissolution rate was 90% in 45 minutes.

[0052] Alkaline layer prescription: Potassium dihydrogen phosphate 10% (w / v), add water to 100%, and the coating process is the same as in Example 1. The weight of the coating increased by 12%, and the ball core containing the basic layer was obtained.

[0053] Hysteresis layer prescription w / v(%)

[0054] Polyacrylic resin III (Eudragit S100) 6

[0055] Micronized silica gel 1.4

[0056] Add 95% ethanol to 100%,

[0057] The coating process is the same as in Example 1. Coating weight gain of 180%. The obtained pulse pellet release curve is shown in the appendix figure 2 : Lags for about 3.5 hours, then releases completely wi...

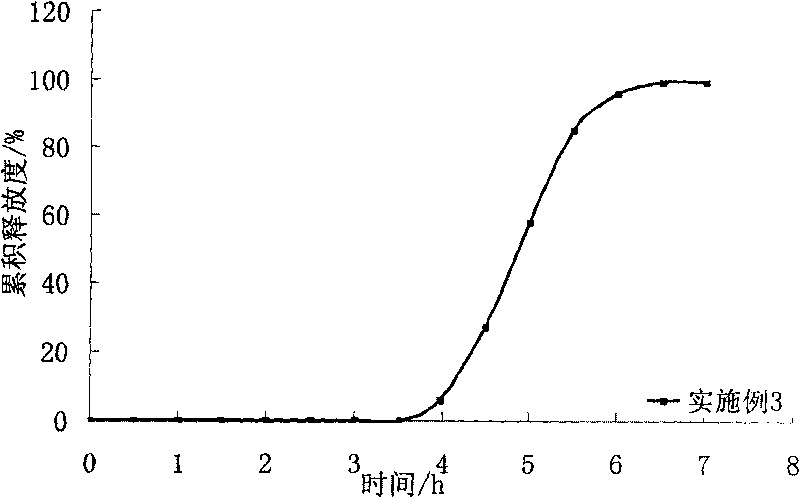

Embodiment 3

[0059] Whole prescription of immediate-release pill core containing main drug w / w(%)

[0060] Metoprolol Tartrate 30

[0061] Low-substituted hydroxypropyl cellulose 40

[0062] Microcrystalline Cellulose 30

[0063] Preparation process: add 5% HPMC in 70% ethanol solution to make soft material, extrude the soft material through the sieve plate of the extruder (aperture 0.8mm), put the strip particles in the spheronizer and spheronize, and dry the ball core at 50°C After 5 hours, 18-24 mesh drug cores were sieved to obtain immediate-release pellet cores containing the main drug. The average cumulative dissolution rate in 45 minutes was 99%.

[0064] Basic layer: sodium carbonate 10% (w / v), add water to 100%, the coating process is the same as in Example 1. Coating weight gain 25%;

[0065] Hysteresis layer prescription w / v(%)

[0066] Polyacrylic resin III (Eudragit S100) 8

[0067] Dibutyl sebacate 1

[0068] Glycerin 0.2

[0069] Talc 1.5

[0070] Add 95% ethanol t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com