Cleaning-free lead-free solder soldering fluid

A lead-free solder and flux technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of flammability of organic solvents, increase of production costs, waste of resources, etc., and achieve high electrical insulation performance, Improved soldering performance and less flux residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the no-cleaning lead-free solder flux of the present embodiment, it is made up of the component of following weight ratio:

[0024] Refined hydrogenated rosin 87%, benzoic acid 1.0%, sebacic acid 0.5%, 12-hydroxystearic acid 6.0%, 5-fluorosalicylic acid 1.5%, SAF-254.0%.

[0025] The no-clean lead-free solder flux of the present embodiment is prepared by the following preparation method:

[0026] Add 8.7kg of refined modified rosin into a container with stirring and heater, heat and stir to completely melt the refined hydrogenated rosin, then add 0.40kg of SAF-25 at 130~150oC, after stirring evenly, add 0.1kg of benzoic acid , 0.05kg of sebacic acid and 0.15kg of 5-fluorosalicylic acid were stirred evenly, and finally 0.6kg of 12-hydroxystearic acid was added until the mixture was evenly stirred to obtain the no-cleaning lead-free solder flux.

Embodiment 2

[0028] According to the no-cleaning lead-free solder flux of the present embodiment, it is made up of the component of following weight ratio:

[0029] Refined hydrogenated rosin 86%, benzoic acid 1.0%, phthalic acid 1.0%, cetylpyridine bromide 1.0%, benzyl benzoate 5.0%, 12-hydroxystearic acid methyl ester 6.0%.

[0030] The preparation method is the same as in Example 1.

Embodiment 3

[0032] According to the no-cleaning lead-free solder flux of the present embodiment, it is made up of the component of following weight ratio:

[0033] Refined hydrogenated rosin 84%, 12-hydroxystearic acid 6.0%, benzoic acid 2.0%, octanoic acid 1.0%, SAF-25 3.0%, oxidized polyethylene wax 3.0%, 5-chlorosalicylic acid 1.0%.

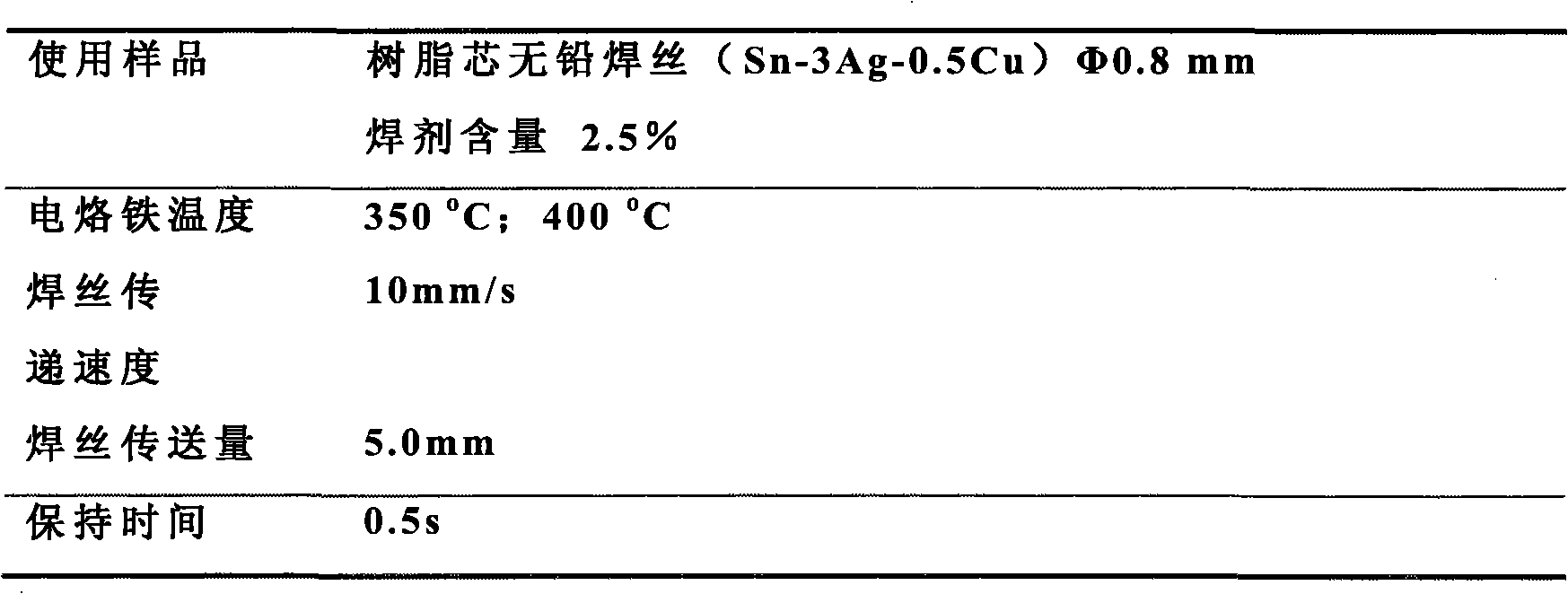

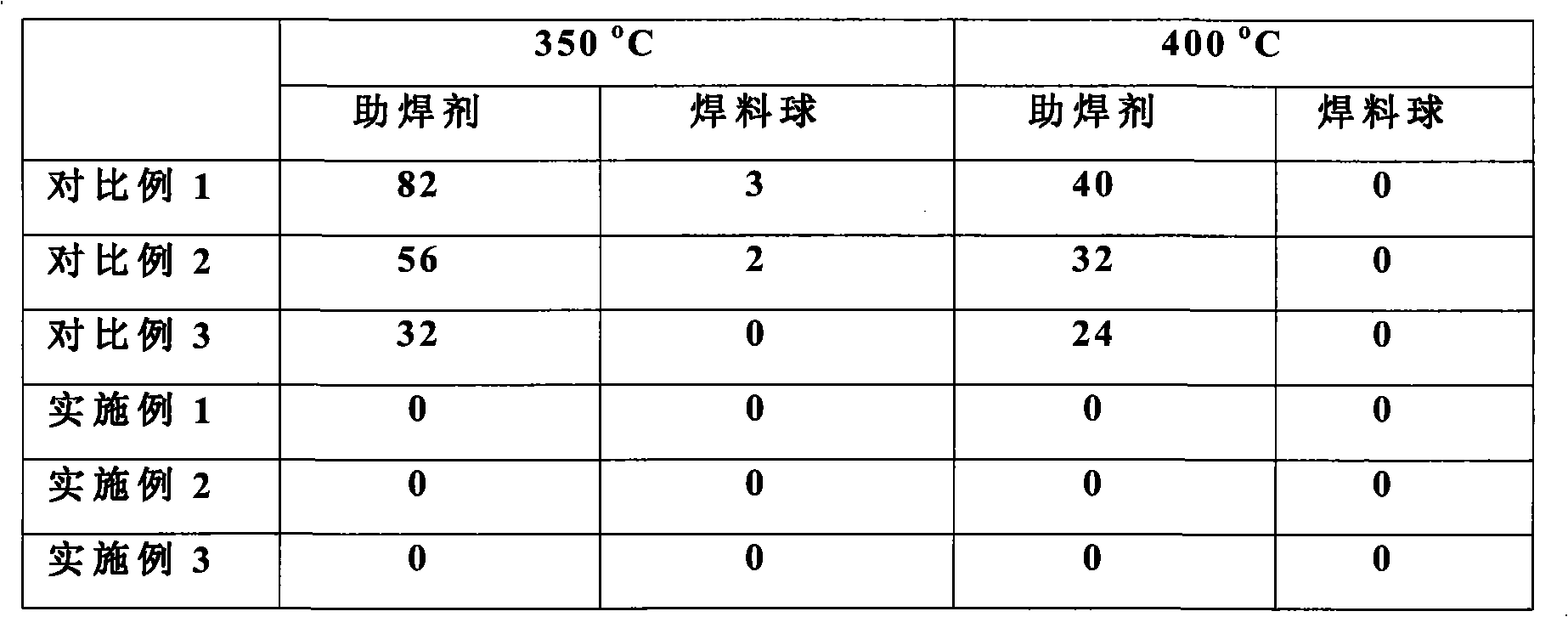

[0034] A solder ball splash test and an ion contamination test were respectively carried out on the fluxes in the above-mentioned embodiments and the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com