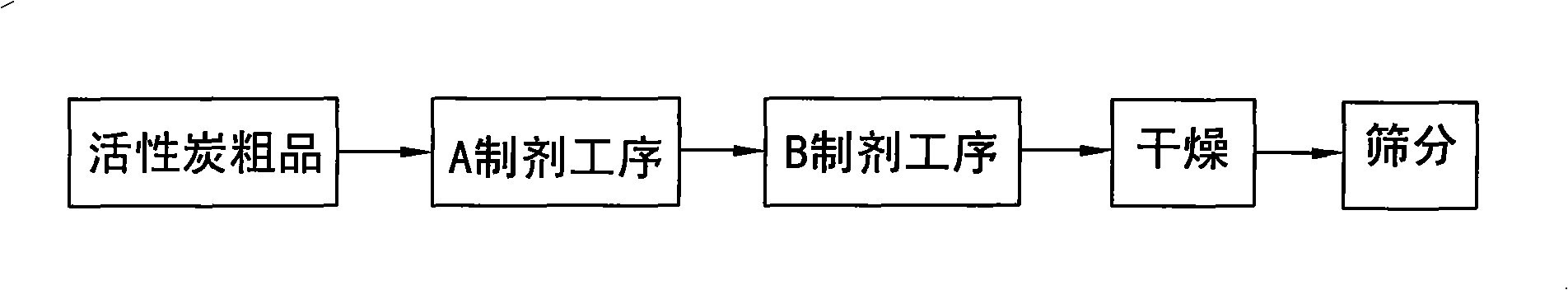

Absorbent charcoal fine purification technique

A technology of activated carbon and process, applied in the field of activated carbon reprocessing technology, can solve the problems of limiting the application of activated carbon and high impurity content, and achieve the effect of reducing the impurity content and reducing ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

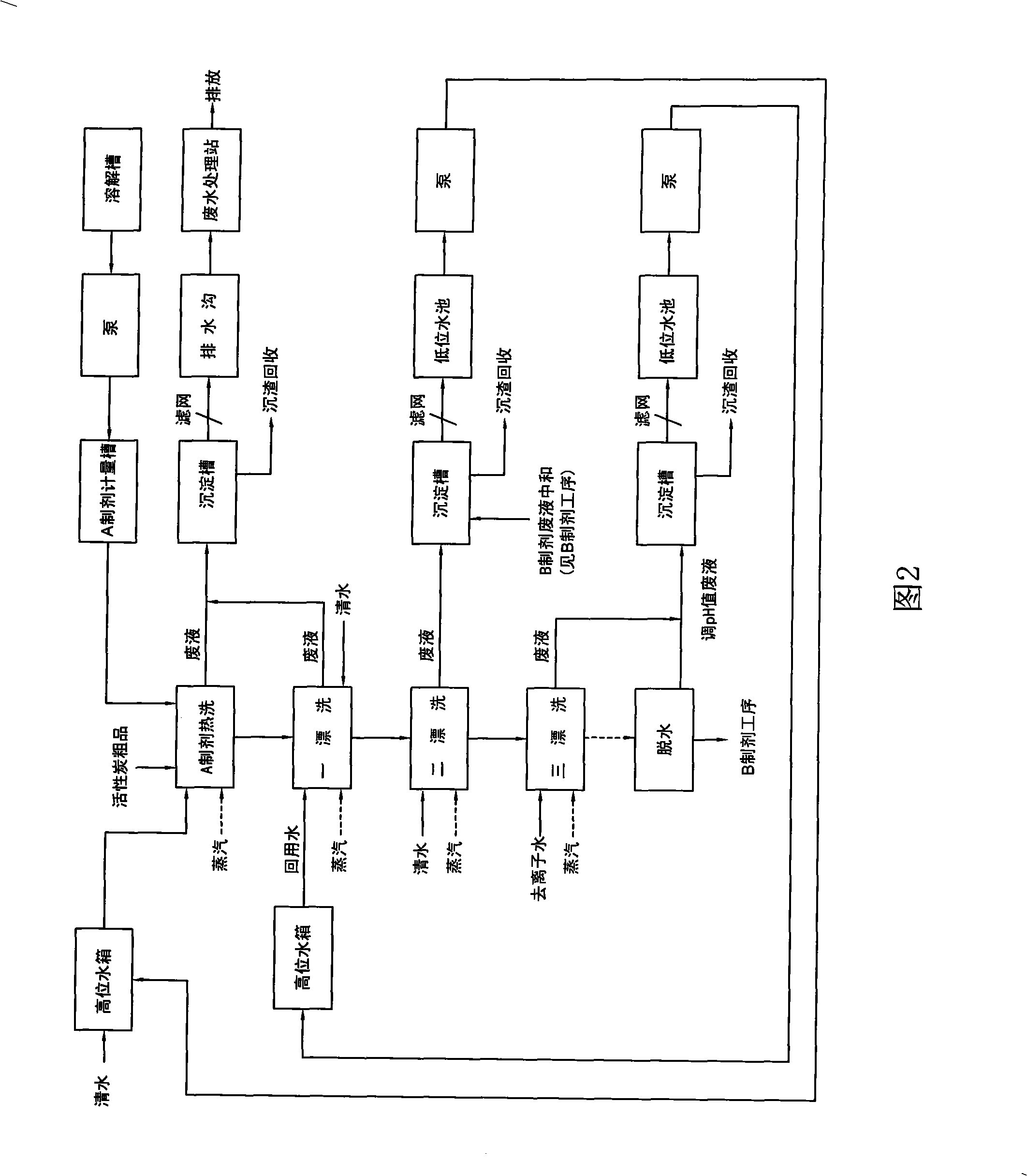

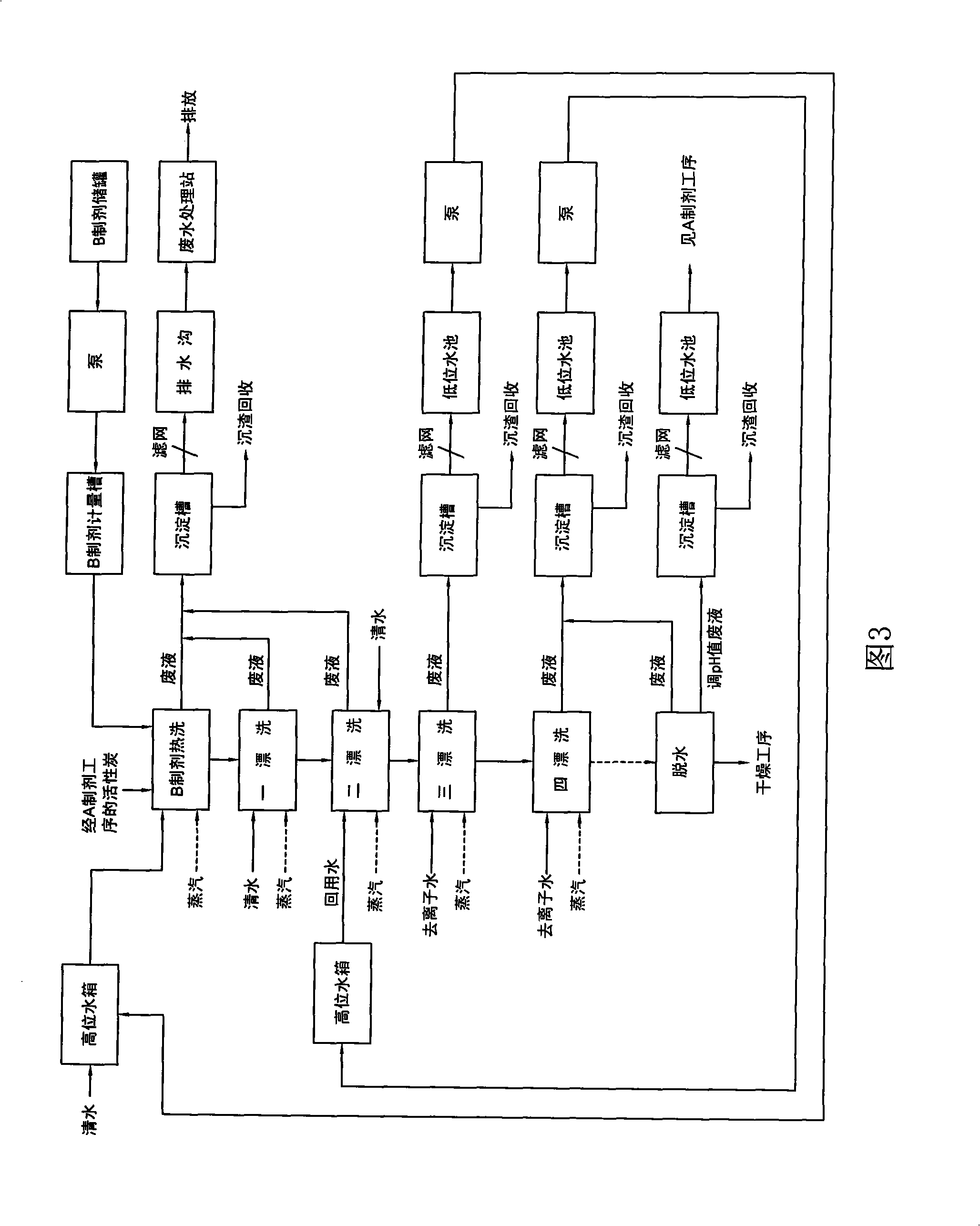

Method used

Image

Examples

Embodiment 1

[0051] The iodine value of the crude activated carbon is 900mg / g, the methylene blue value is 190mg / g, the ash content is 5.4%, and the water content is 9%. Put 60g of activated carbon and 120g of preparation A into a 250ml reactor. Preparation A is a potassium hydroxide solution with a concentration of 7% by weight. After the temperature rises to 60°C, stir and keep warm for 1h. Wash twice, wash to neutral pH, and filter again. Put this gac and 120g B preparation into the reactor of 250ml again, B preparation is the hydrochloric acid solution of concentration 10%, stir reaction 1h at 25 ℃, wash 5 times at 50 ℃ with 300g water after filtering each time to neutrality, in After drying at 150°C for 3 hours, according to the test method of the national standard GB / T12496-1999 of the People's Republic of China, the iodine value of the activated carbon is 965mg / g, the methylene blue value is 195mg / g, the ash content is 0.91%, and the moisture content is 9%.

Embodiment 2

[0053] The iodine value of the crude activated carbon is 950mg / g, the methylene blue value is 195mg / g, the ash content is 6.5%, and the water content is 9%. 30g of activated carbon and 300g of preparation A are dropped into a 500ml reactor. Preparation A is a sodium carbonate solution with a concentration of 15% by weight. After the temperature rises to 90°C, stir and keep warm for a reaction time of 5 hours. The value was washed to neutral, and filtered again. Put this gac and 300g B preparation into the reactor of 500ml again, B preparation is the nitric acid solution of 10% by weight concentration, stir and react at 50 ℃ for 5h, after filtering, wash 3 times at 80 ℃ with 150g water each time to neutral After drying at 150°C for 3 hours, the iodine value of the activated carbon is 965 mg / g, the methylene blue value is 195 mg / g, the ash content is 0.91%, and the water content is 9%.

Embodiment 3

[0055] The iodine value of the crude activated carbon is 1005 mg / g, the methylene blue value is 190 mg / g, the ash content is 5.4%, and the water content is 9%. Activated carbon 60g, preparation A 300g are dropped in the reactor of 500ml, and preparation A is the sodium hydroxide solution of 10% weight percent concentration, after temperature rises to 110 ℃, stir and keep warm reaction time 10h, wash 5 times with 300g water each time after filtering The pH value was washed to neutral, and filtered again. Then this gac and 300gB preparation are dropped into the reactor of 500ml, and B preparation is the hydrofluoric acid solution of 10% weight percent concentration, stirs and reacts 10h at 75 DEG C, washes 5 times at 60 DEG C with 300g water at every turn after filtering. Neutral, after drying at 150°C for 3 hours, the activated carbon has an iodine value of 1010mg / g, a methylene blue value of 195mg / g, an ash content of 0.8%, and a moisture content of 8.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Methylene blue value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com