Protective cover for corrosion prevention and corrosion repair, and application thereof

A corrosion protection and protective cover technology, applied in water conservancy projects, marine engineering, water conservancy engineering equipment and other directions, can solve the problem of reducing the bonding strength and anti-corrosion performance between paint and steel surface, and is not suitable for repairing steel structures in the sea, and protection such as painting paint. Difficulties and other problems, to achieve the effect of saving manpower and material resources, simple structure and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

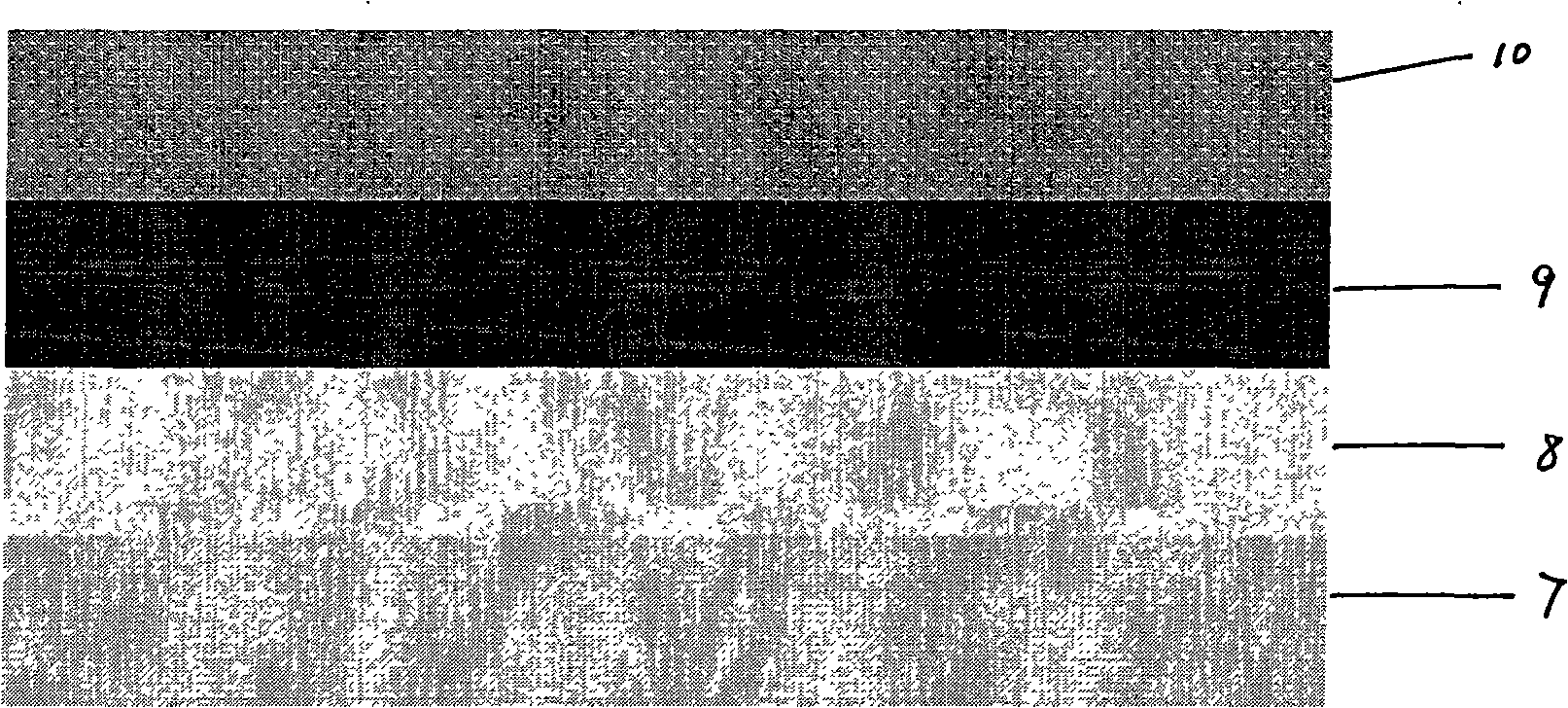

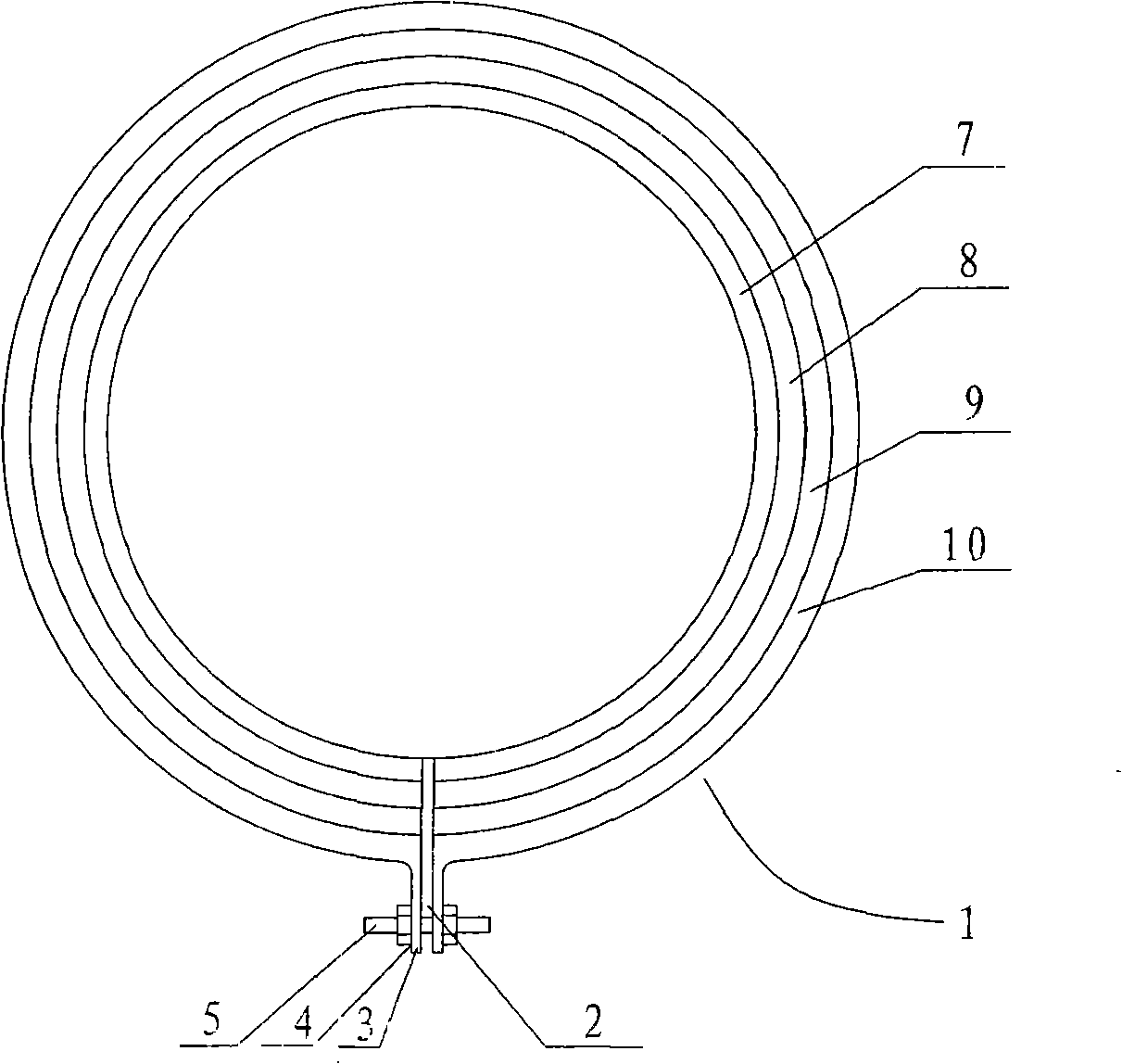

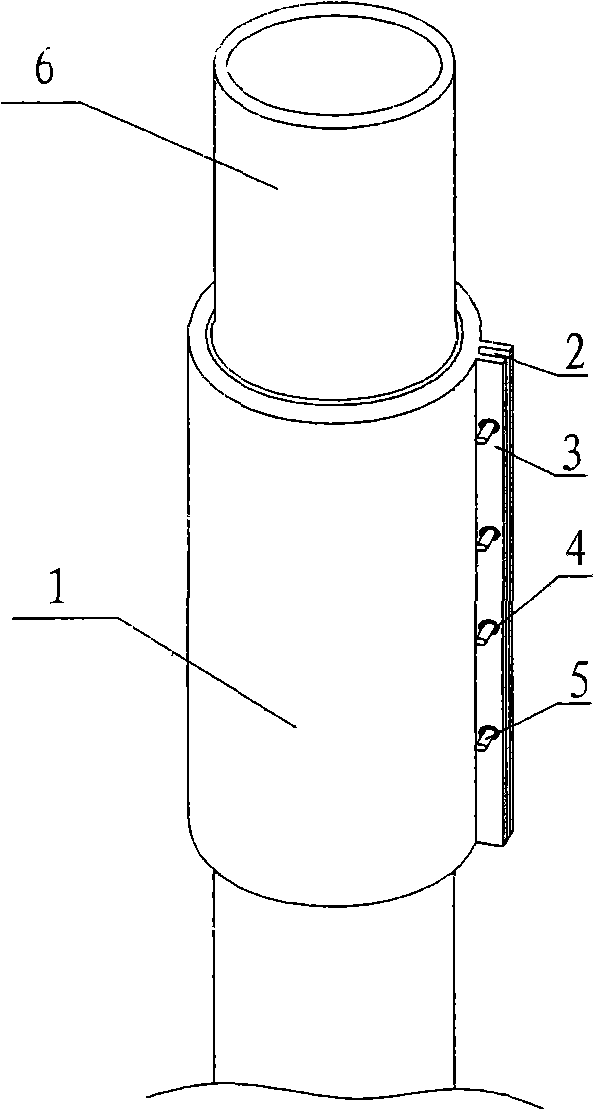

[0026] The protective cover consists of an anti-fouling material layer 10, a high-strength protective material layer 9, a polyester non-woven fabric layer 8 and an anti-rust grease layer 7 from the outside to the inside (see figure 1 ); The protective sleeve 1 has a connecting portion 2 in the axial direction, and two opposite sides of the connecting portion are provided with folded edges 3 that are upwardly tilted.

[0027] The connecting portion 2 is provided with a hole 4, and a bolt 5 is inserted into the hole 4 to fasten the inner layer of the protective sleeve and the steel material 6 to be protected.

[0028] The anti-fouling material, high-strength protective material and the polyester non-woven fabric are bonded into one body with an adhesive, and then anti-rust grease is applied to the polyester non-woven fabric to form an anti-rust of about 1 mm Grease layer. There is a covering paper (not shown in the figure) on the surface of the inner anti-rust grease, which is torn...

Embodiment 2

[0033] The antifouling material in the protective cover can also be: silicone coating, fluorocarbon coating, polytetrafluoroethylene, polyperfluoroethylene propylene, tetrafluoroethylene-perfluorovinyl ether copolymer or polycarbonate with a molecular weight of 3-8 million Ethylene; high-strength protective material: nylon reinforced neoprene or polyurethane resin; anti-rust grease: containing mineral grease, oil-soluble corrosion inhibitor, antioxidant and anticorrosive agent and metal passivator, of which oil-soluble corrosion inhibitor The agent is one or more of metal sulfonates, metal carboxylic acid soaps and lanolin soaps, and the antioxidant and anticorrosive agent is thion octyl alcohol zinc salt or phosphoric acid fatty alcohol zinc salt or thion phosphorated alkene calcium salt , The metal deactivator is a benzotriazole derivative (T551) or a thiadiazole derivative (T561).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com