Hollow metallic ball with mesopore structure and preparation method and application thereof

A mesoporous structure and metal sphere technology, applied in the field of metal catalysts, can solve problems such as hollow structure damage, and achieve the effects of low cost, simple preparation process, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) At 15 ~ 30 ℃, to Bu t PdCl was added dropwise to PBr surfactant aqueous solution 2 Aqueous solution, after dropping, continue stirring for 5-15 minutes to obtain a turbid solution, wherein: the molar ratio of surfactant to metal salt is 20:1, and the molar ratio of metal salt to rare earth metal salt is 9:0;

[0026] 2) At 25°C, quickly add KBH to the above mixed solution 4 Aqueous solution, stirred vigorously for 10 minutes, black particles are gradually formed in the solution, and gas emerges, wherein: the molar ratio of metal borohydride compound to metal salt in the water phase is 4:1;

[0027] 3) Filter the black particles generated in step 2), and then wash with deionized water and absolute ethanol for 3 to 5 times respectively to obtain the target object-hollow Pd spheres with a mesoporous structure, represented by Pd (hollow).

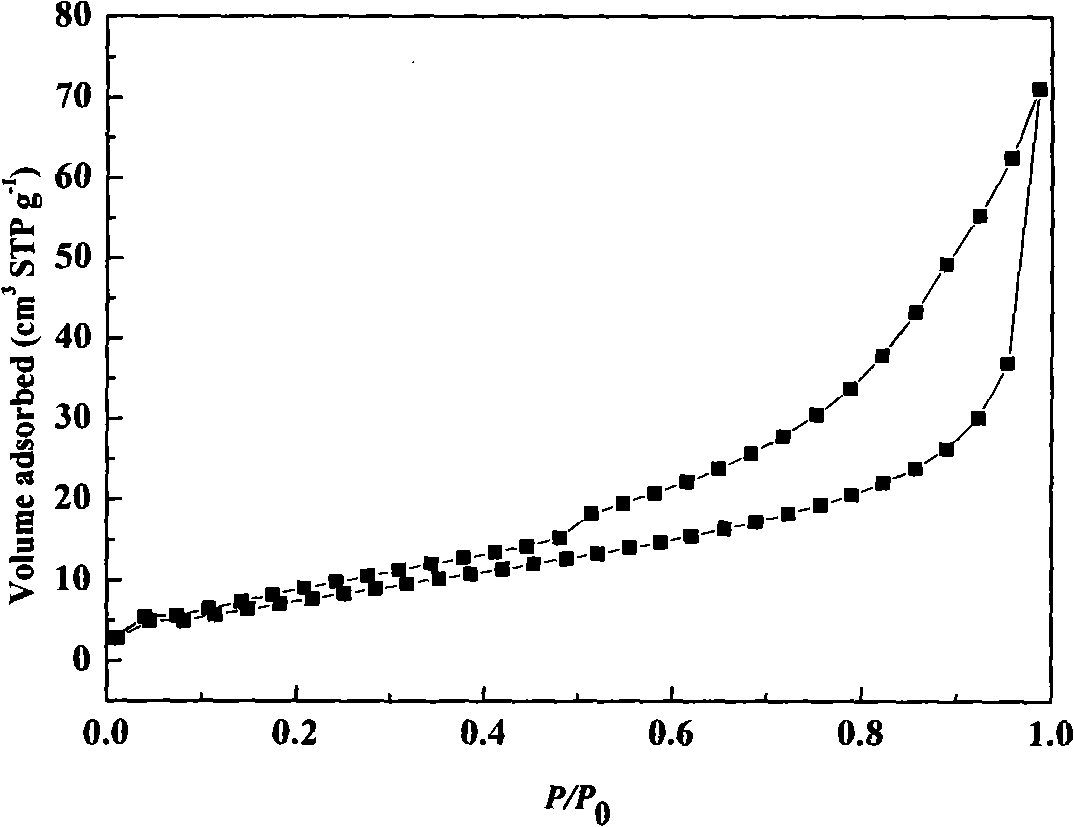

[0028] figure 1 For the N of the sample prepared in this embodiment 2 Adsorption-desorption isotherm, from the shape of the isot...

Embodiment 2

[0031] 1) At 15 ~ 30 ℃, to Bu t PdCl was added dropwise to PBr surfactant aqueous solution 2 Aqueous solution and Ce(NO 3 ) 3 The mixed solution of the aqueous solution, after dropping, was continued to stir for 5 to 15 minutes to obtain a turbid solution, wherein: the molar ratio of the surfactant to the metal salt was 20:1, and the molar ratio of the metal salt to the rare earth metal salt was 9:1;

[0032] 2) At 25°C, quickly add KBH to the above mixed solution 4 Aqueous solution, stirred vigorously for 20 minutes, black particles are gradually formed in the solution, and gas emerges, wherein: the molar ratio of metal borohydride compound to metal salt in the water phase is 4:1;

[0033] 3) filter the black particles generated in step 2), then wash with deionized water and absolute ethanol for 3 to 5 times respectively to obtain the target object-hollow Pd-Ce spheres with mesoporous structure, use Pd-Ce (hollow )express.

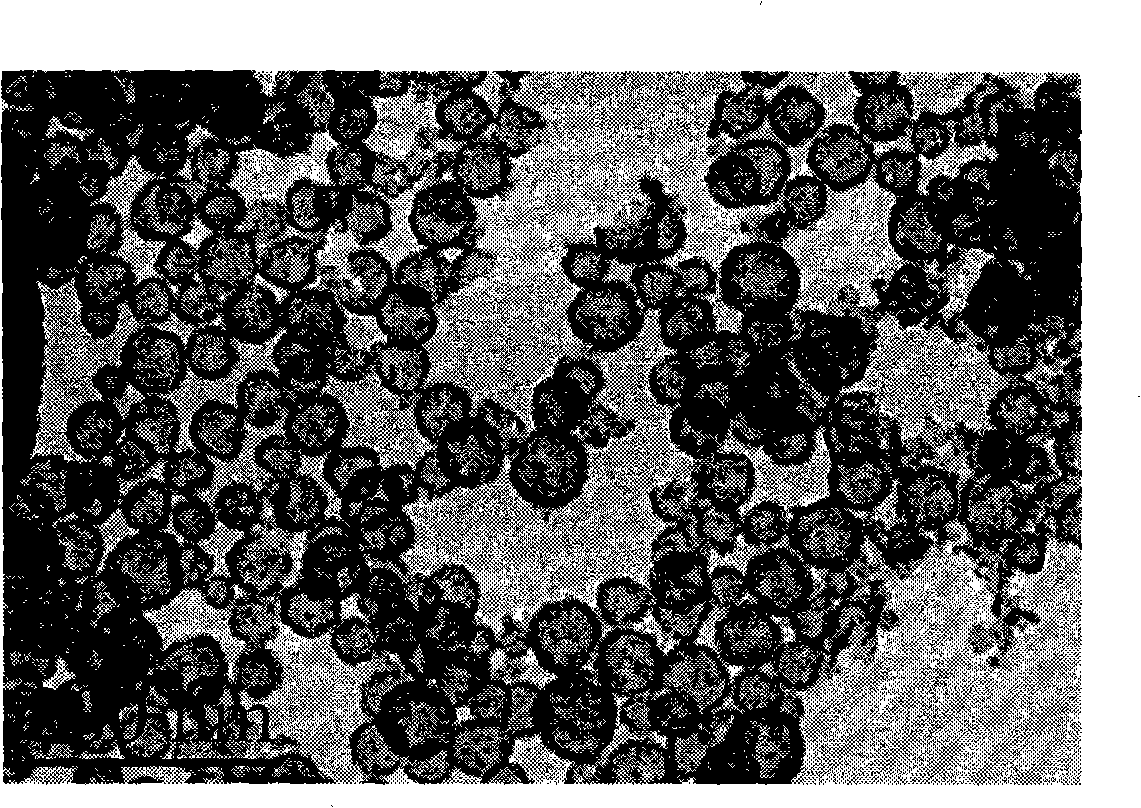

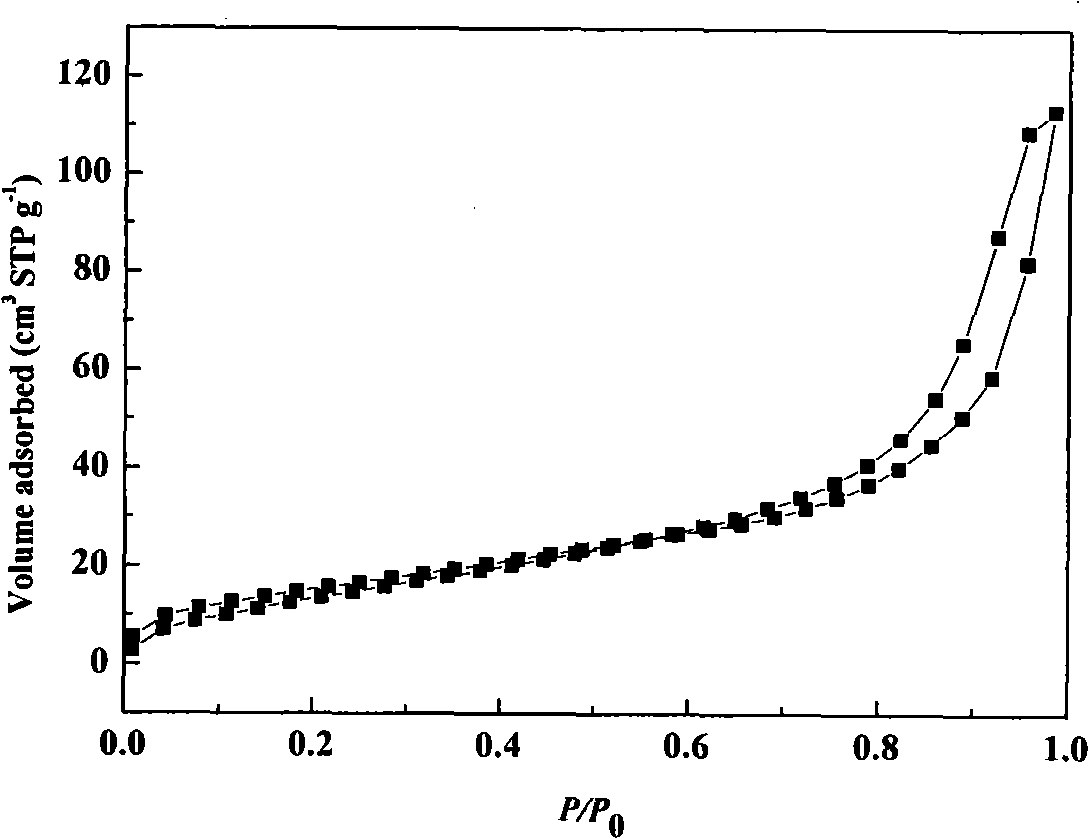

[0034] image 3 For the N of the sample prepa...

Embodiment 3

[0037] The difference between this example and Example 2 is that the molar ratio of the surfactant to the metal salt used is 2:1, and the rest of the content is the same as that described in Example 2.

[0038] The N of the sample prepared by this embodiment 2The adsorption-desorption isotherm can be determined to be that the obtained sample has a mesoporous structure; it can be seen from the TEM photo of the sample prepared in this embodiment that the obtained sample is a hollow sphere, the outer diameter of the spherical shell is 10nm, and the wall thickness of the spherical shell is 2nm; using QuantaChrome The Nova 4000e automatic physical adsorption instrument measures the specific surface area and pore structure of the metal catalyst. It can be known that the active specific surface area of the metal nanoparticles with mesoporous structure is 50m 2 / g, the pore diameter is 2nm, and the pore volume is 0.8cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com