Hollow fiber anion-exchange membrane and preparation method thereof

An anion exchange membrane, hollow technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven distribution of groups, expensive chemical reagents, loss of groups, etc. The effect of spinning and slurry viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

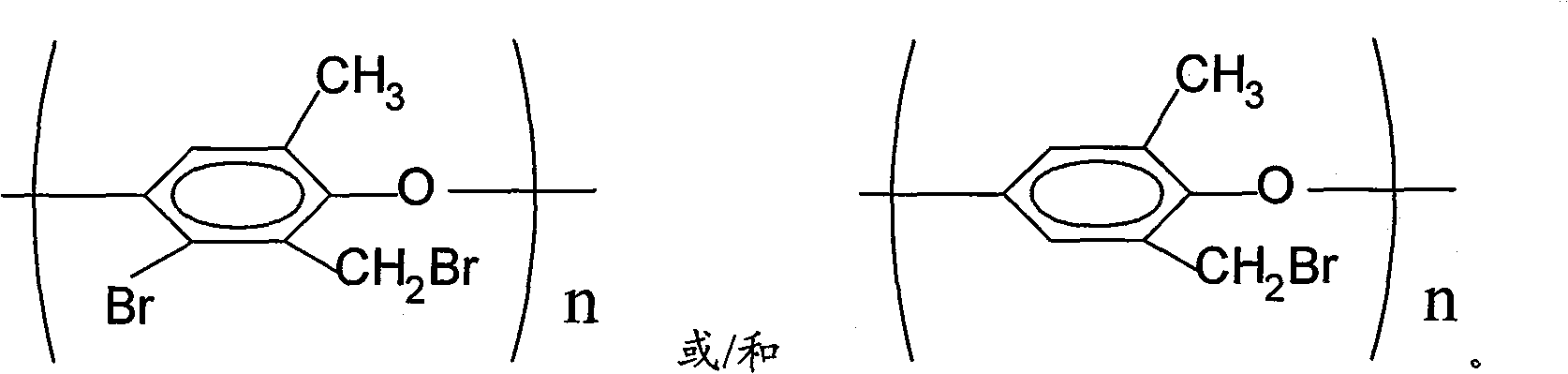

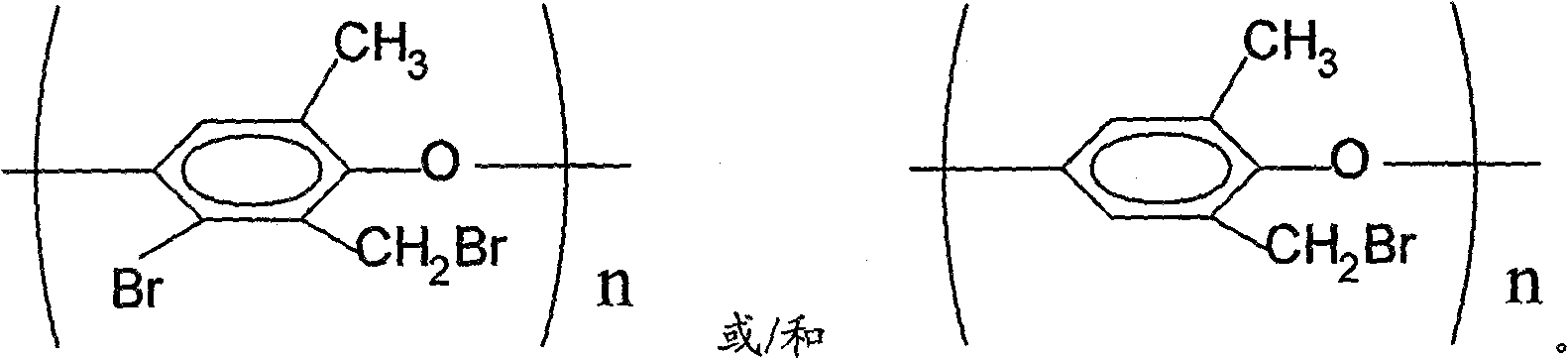

[0022]Preparation of hollow fiber base membrane: dissolving brominated polyphenylene ether with a methyl bromination degree of 60% in N-methylpyrrolidone to prepare a spinning solution with a polymer mass concentration of 20%, and the spinning solution After filtering, put it into the slurry tank, adopt the dry jet wet spinning method to form, adjust the control frequency of the slurry metering pump to 17Hz, control the spinning pressure at 0.2-0.4MPa, and the spinning solution is extruded from the spinneret composed of two concentric tubes , after a 500mm dry spinning process, solidify in a water bath with a temperature of 15-50°C, the filling liquid in the spinneret cavity is water, the flow rate is 0.1-0.3ml / min, and the control frequency of the winding speed is 7Hz, and the obtained A hollow fiber base membrane with a thickness of 170 μm and an inner diameter of 350 μm.

[0023] Preparation of hollow fiber anion exchange membrane: take out the hollow fiber base membrane pr...

Embodiment 2

[0027] Preparation of hollow fiber base membrane: Dissolve brominated polyphenylene ether with methyl bromination degree of 90% and benzene ring bromination degree of 20% in dimethylformamide to prepare a polymer with a mass concentration of 38%. Spinning solution, the spinning solution is filtered and added to the slurry tank, formed by dry jet wet spinning, the control frequency of the slurry metering pump is adjusted to 28Hz, the spinning pressure is controlled at 0.2-0.4Pa, and the spinning solution is obtained from two The spinneret composed of concentric tubes is extruded, and after a dry spinning process of 500mm, it is solidified in a water bath at a temperature of 28-31°C. The filling liquid in the spinneret cavity is water, and the flow rate is 0.1-0.3ml / min. The control frequency of the wire speed was 14 Hz, and a hollow fiber base membrane with a thickness of 400 μm and an inner diameter of 1000 μm was obtained.

[0028] Preparation of hollow fiber anion exchange m...

Embodiment 3

[0032] Using the same operation process as in Example 2, but changing the mass concentration of the polymer to 60%, a film with a similar structure can be obtained.

[0033] Structural and performance tests were carried out on the hollow fiber anion exchange membrane prepared above in this example. The composition of the membrane is quaternized brominated polyphenylene ether, the degree of bromination of the benzene ring is 20%, and the degree of methyl bromination is 37%. %; the thickness of the hollow fiber membrane is 600 μm, the inner diameter is 1200 μm, the anion exchange capacity is 2.40 mmol / g dry membrane, and the water content is 80%.

[0034] Since the hollow fiber anion exchange membrane product of the invention has higher anion exchange capacity and water content, it can be used in the field of acid recovery by diffusion dialysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com