Preparation method and use of camellin A and camellin B

A technology of camelliaside and shiya tea, which is applied in the field of botanical medicine to achieve the effects of reasonable design, short production cycle and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 camelliaside A

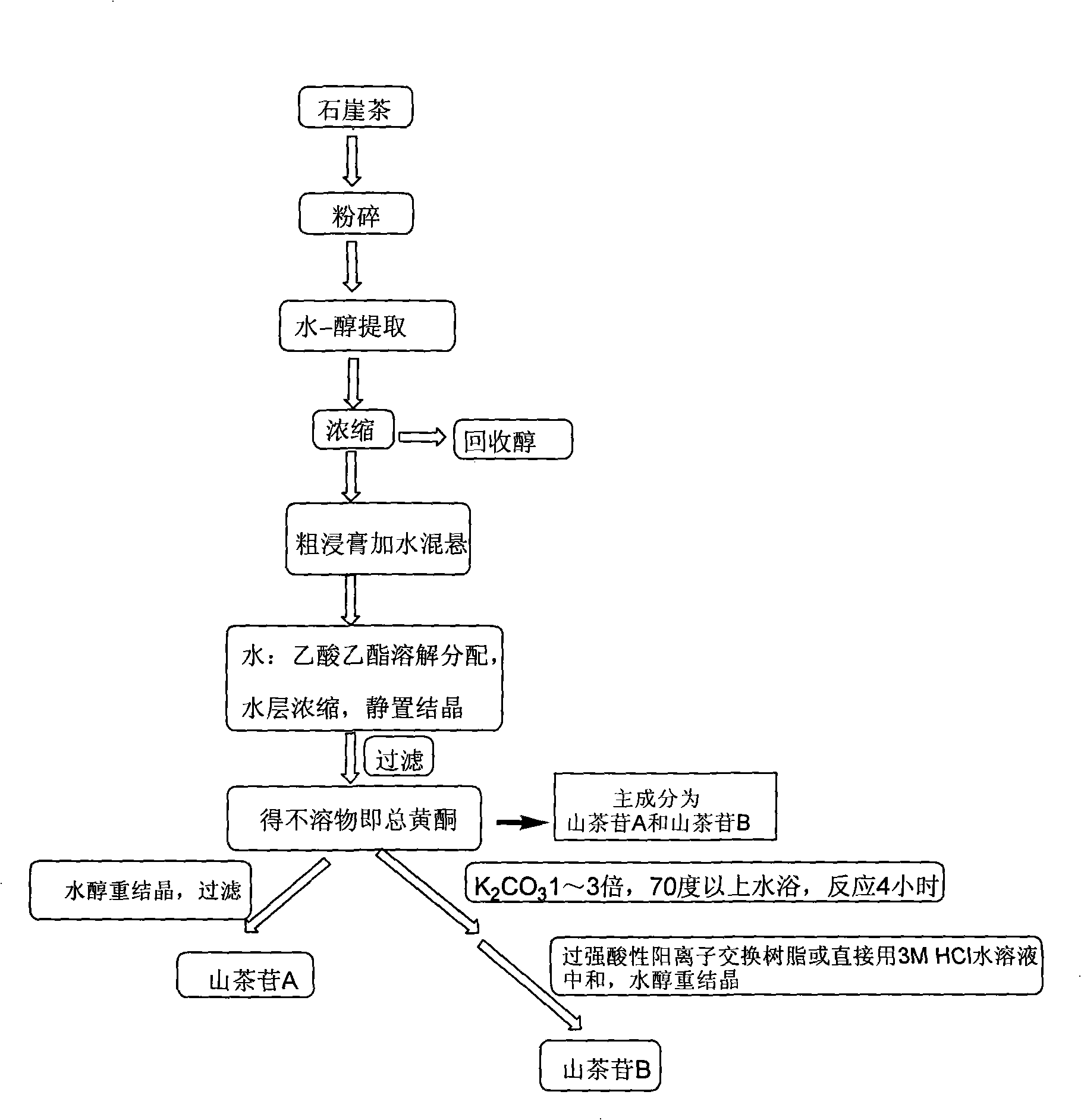

[0025] see figure 1 250g of Shiya tea was taken, crushed until the particle size was below 10mm, placed in a 5000ml round bottom flask, added 3000ml of 80% methanol for reflux extraction for 1 hour, filtered and then added 80% methanol 2000ml for reflux extraction for 1 hour, and combined the two The extract was concentrated to 500ml, extracted twice with 500ml ethyl acetate, and the water layer was further concentrated to 250ml, placed at a temperature of 10°C for crystallization for 2 hours, filtered to obtain yellow total flavonoids of Shiya tea, and the total The flavonoids were crystallized twice with 95% ethanol and 50% ethanol successively to obtain camelliaside A with a purity of 93.6% and a yield of 8.6%.

Embodiment 2

[0026] The preparation of embodiment 2 camelliaside A

[0027] Take 200g of Shiya tea, crush it until the particle size is below 5mm, put it in a 3000ml round bottom flask, add 1600ml of 50% ethanol for percolation extraction, extract for 7 days for the first time, and extract for 3 days after adding solvent for the second time, Combine the two extracts, recover ethanol and concentrate to 600ml, add an equal amount of ethyl acetate to extract and degrease, continue to concentrate the water phase to 300ml, place it at room temperature for crystallization for 1 hour, and filter to obtain yellow total flavonoids of Shiya tea. The flavonoids were crystallized twice with methanol and 80% methanol successively to obtain catechin A with a purity of 91.8% and a yield of 9.5%.

Embodiment 3

[0028] The preparation of embodiment 3 camelliaside A

[0029] Take 300g of Shiya tea, crush it until the particle size is less than 5mm, put it in a 5000ml round bottom flask, add 3000ml of methanol for ultrasonic extraction, extract for 40 minutes for the first time, add solvent for the second time, extract for 20 minutes, and combine twice The extract was concentrated after recovery of methanol to obtain an extract, which was suspended in 600ml of water, added an equal amount of ethyl acetate for extraction and degreasing, and the water phase was further concentrated to 300ml, placed at room temperature for crystallization for 1 hour, and filtered to obtain a yellow The total flavonoids of Shiya tea were crystallized twice with ethanol and 70% ethanol successively to obtain camelliaside A with a purity of 92.8% and a yield of 8.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com