Production method of colistin rough material powder

A colistin and raw material technology, which is applied in the field of colistin raw material powder manufacturing, can solve the problems of increased manufacturing time and decreased recovery rate of the target substance colistin raw material powder, and achieves the effect of high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]For the Bacillus polymyxa variant colistin 202-71 strain currently used in the manufacture of colistin raw material powder, pass NTG at a concentration of 10-1000 μg / mg, stand or shake at a temperature of 25-30°C for 1 minute- After 24 hours, mutagenesis was performed, and colonies were cultured on agar plates containing 2% tryptone, 0.2% yeast extract and 1% glucose. Each colony (bacterial strain) was inoculated on a liquid seed medium containing 2% common broth, 0.2% yeast extract and 0.3% sodium chloride, and after culturing at 28°C for about 24 hours, about 0.1 mL was inoculated into the 30mL contains 4.5% cornflower, 1.5% corn flour, 0.2% wheat germ, 0.2% defatted soybean, 1% ammonium sulfate, 0.05% potassium dihydrogen phosphate, 0.005% ferrous sulfate, 0.05% calcium carbonate and 1.5% starch syrup Liquid medium in a 250mL Erlenmeyer flask. After culturing with shaking at 28° C. for about 120 hours, the culture solution was filtered using filter paper, and the col...

Embodiment 2

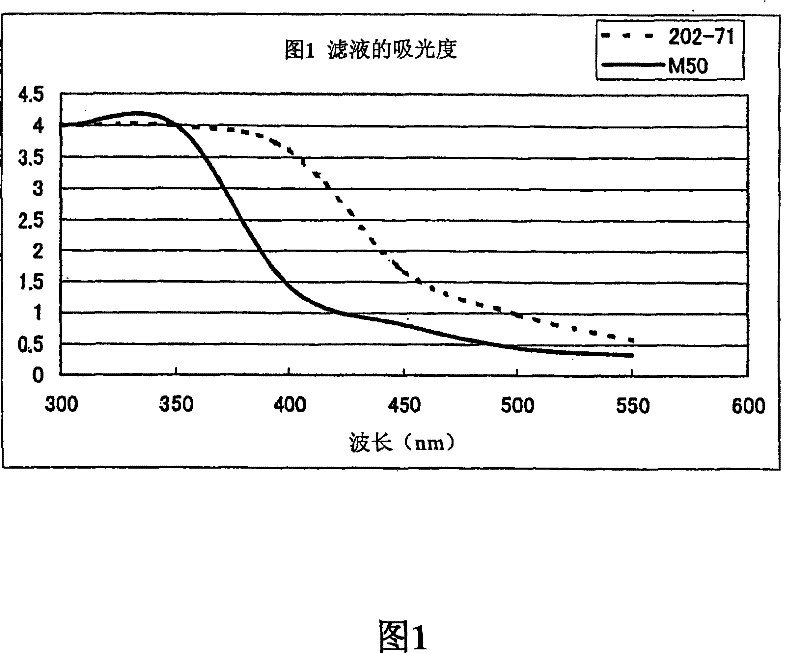

[0041] Inoculate the M50 strain with light coloring of the culture solution obtained in Example 1 and the 202-71 strain with dark coloration of the culture solution used in the existing colistin fermentation production into a mixture containing 2% of common broth, 0.2% of yeast extract and chlorine After culturing at 28°C for about 24 hours in a liquid seed medium with 0.3% sodium chloride, inoculate about 15 mL of each into 4 L containing 4.5% cornflower, 1.5% corn flour, 0.2% wheat germ, and 0.2% defatted soybean. , Ammonium sulfate 1%, Potassium dihydrogen phosphate 0.05%, Ferrous sulfate 0.005%, Calcium carbonate 0.05% and Saccharin 1.5% liquid culture medium in the 5L capacity fermenter tank. Cultivate for about 120 to 144 hours at pH 5.0 to 7.0 and 30° C. under ventilation and stirring respectively. The culture solution obtained by filtering the filter paper was used to measure the absorbance at 400nm. As a result, compared with 4.50 of the culture filtrate from the 202-...

Embodiment 3

[0045] The 5 L fermenter culture liquid obtained in Example 2 of the M50 strain and the 202-71 strain was filtered through a suction filter (Nutsche) coated with a filter aid (Bodymix), and then adsorbed to the ions packed in the column. Exchange resin (アンバライトIRC-50 (Na + type) made by Romland Haus Co., Ltd., 300 mL). After eluting colistin from the ion exchange resin with about 0.4mol / L sulfuric acid, wash with 600mL deionized water, and concentrate the mixed solution of the eluent and washing solution to about 5% concentration (W / V) , to obtain colistin high content liquid. The absorbance at 400nm of the colistin high content liquid, compared with 0.359 of the colistin high content liquid from the 202-71 strain, the colistin high content liquid from the M50 strain was 0.07, obviously the mulistin from the M50 strain The coloring of the mycocin high-content solution was light (Table 3).

[0046] table 3

[0047] strain

Absorbance (400nm)

Solid (%)

pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com