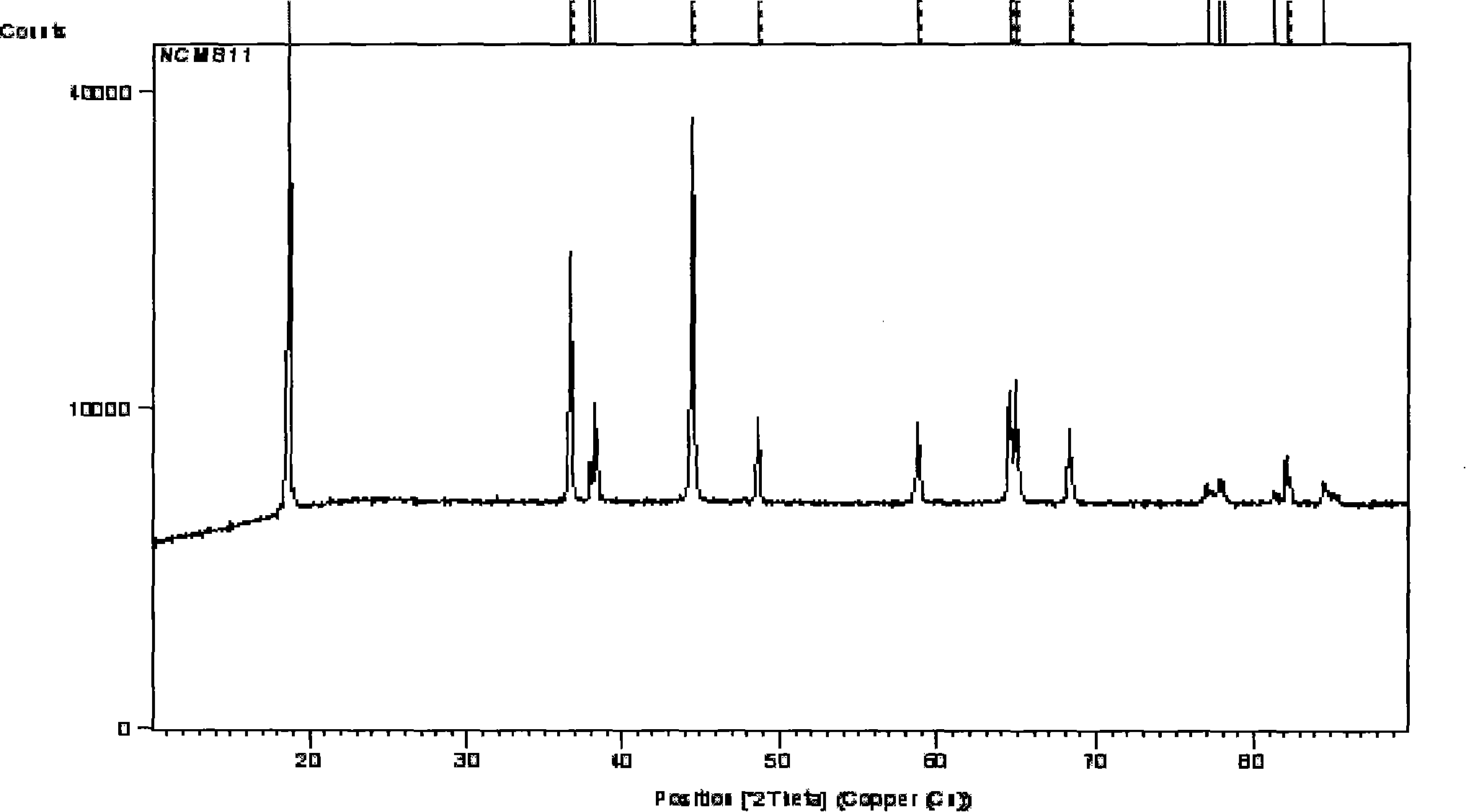

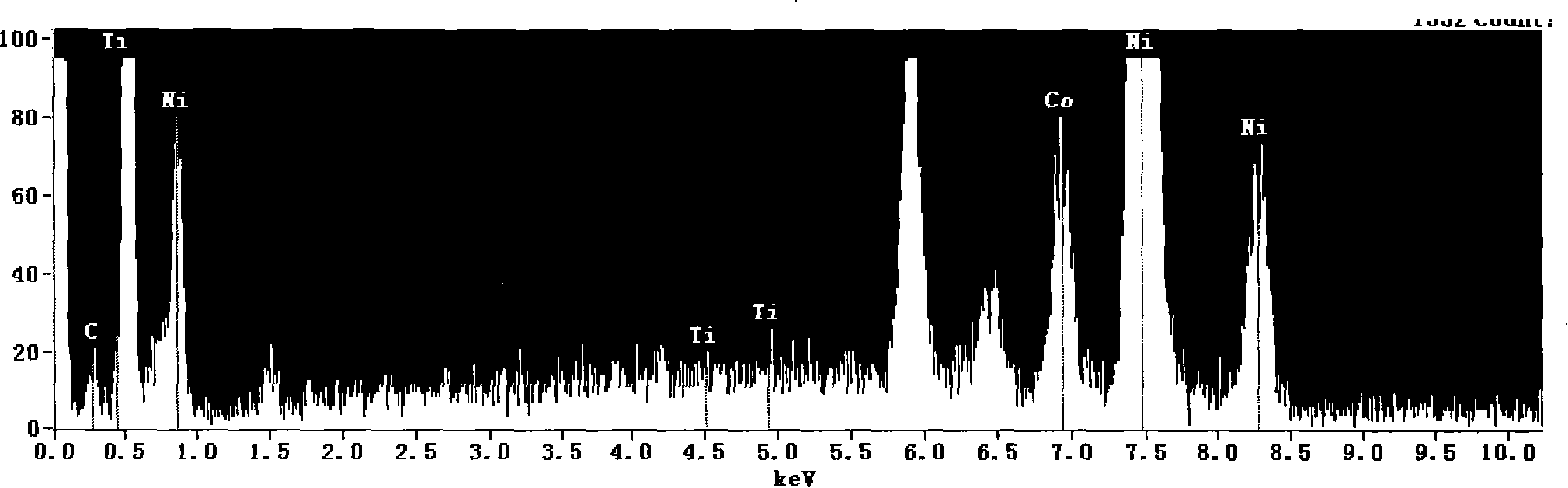

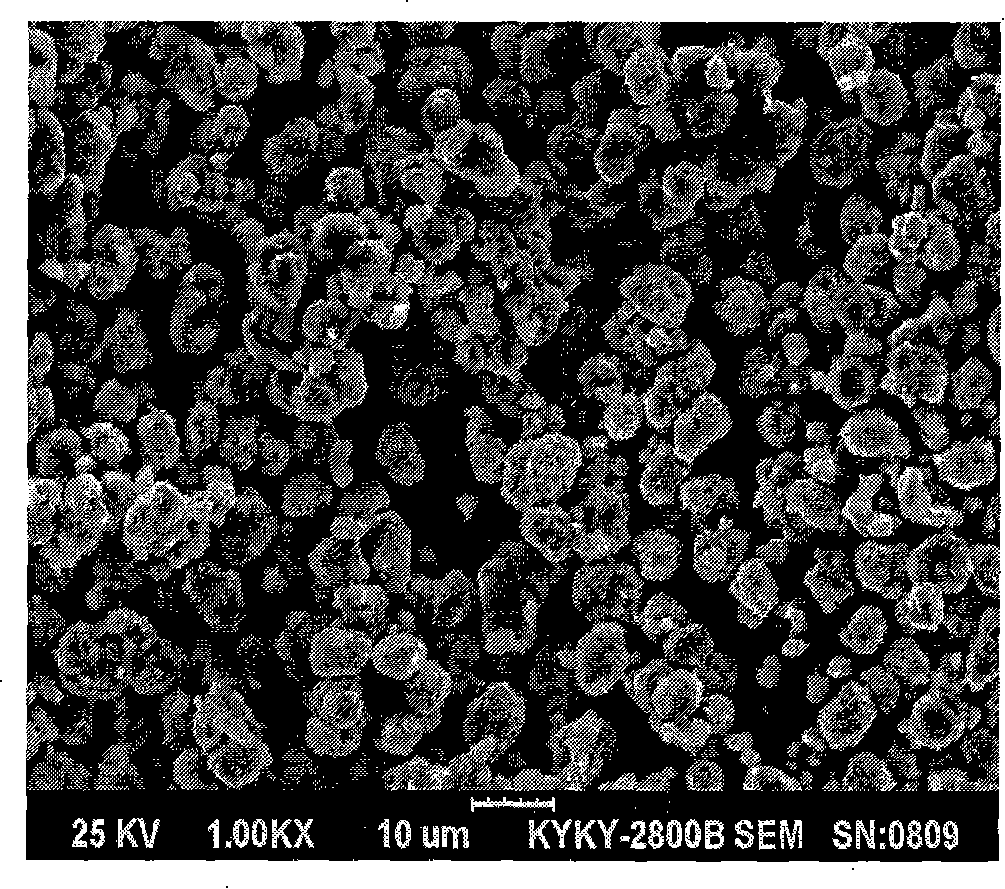

Composite coated positive pole material of lithium ionic cell and preparing method thereof

A composite positive electrode material and lithium-ion battery technology, applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve problems such as gelling, gas swelling, explosion, etc., and achieve simple process, low cost, and controllable procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of lithium-ion battery composite coating cathode material of the present invention comprises the following steps:

[0025] 1. Prepare lithium hydroxide or sodium hydroxide alkali solution with a concentration of 0.5-8 mol / L, and chloride, sulfate or nitrate solutions of nickel, cobalt and manganese with a concentration of 0.5-8 mol / L, in which nickel, cobalt and manganese The molar ratio of salt is 7~9:1~5:1~5, and accounts for the whole solution, the additive of 0~10wt% in the final solution, and additive is ammoniacal liquor, ethylene glycol, ethylenediamine, 12~16 One or both of sodium alkyl sulfonate and polyethylene glycol are added to the reaction kettle at a flow rate of 10-100L / h at the same time, and the pH of the solution is adjusted to 8-11.0 by controlling the dropping rate of the alkali solution, and carried out Stir continuously to make it generate a uniform precipitated powder, which is Ni 0.7 co 0.2 mn 0.1 (OH) 2 、Ni 0.8 co 0...

Embodiment 1

[0032] Embodiment 1, one, prepare the sodium hydroxide alkaline solution of 1mol / L concentration earlier, preparation 1mol / L mol ratio is the nickel nitrate, cobalt nitrate, manganese nitrate solution of 8: 1: 1, preparation concentration is whole solution quality simultaneously A mixed solution of 10wt% ammonia water and ethylene glycol, each prepared solution is added to the reaction kettle at a flow rate of 60L / h at the same time, and continuously stirred to form a uniform precipitate, and the pH of the solution is adjusted by controlling the dropping speed of the alkali solution The value is at 10.8. Filter and wash the precipitated powder in a vacuum filter, measure the pH value of the filtrate to be around 5, and titrate the filtrate with barium nitrate. When there is no obvious precipitation, the filtration ends; Dry the powder at 80°C for 12 hours in a vacuum oven.

[0033] 2. Mix the dried powder with lithium hydroxide at a ratio of 1:1.05 in a powerful disperser (pl...

Embodiment 2

[0040] Embodiment 2, one, prepare the lithium hydroxide alkali solution of 0.5mol / L concentration earlier, the preparation 0.5mol / L molar ratio is the nickel nitrate, cobalt nitrate, manganese nitrate solution of 8: 1: 1, preparation concentration is the whole A mixed solution of ammonia water and ethylenediamine with a solution quality of 0.5wt%, each prepared solution is simultaneously added to the reaction kettle at a flow rate of 10L / h, and continuously stirred to form a uniform precipitate, which is obtained by controlling the dripping rate of the alkali solution. Adjust the pH of the solution to 8.0. Filter and wash the precipitated powder in a vacuum filter, measure the pH value of the filtrate to be around 5, and titrate the filtrate with barium nitrate. When there is no obvious precipitation, the filtration ends; Dry the powder at 120°C for 12 hours in an infrared drying oven.

[0041] 2. Mix the dried powder with lithium hydroxide at a ratio of 1:0.8 in a barrel bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com