Method for preparing agricultural ammonium sulphate and calcined soda for industry with salt cake ammonia soda process

A technology of ammonium sulfate and ammonia-alkali method, applied in chemical instruments and methods, ammonia compounds, carbonate preparations, etc., can solve the problems of high energy consumption, waste water discharge, etc., achieve improved utilization rate, simple process, and broaden production channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

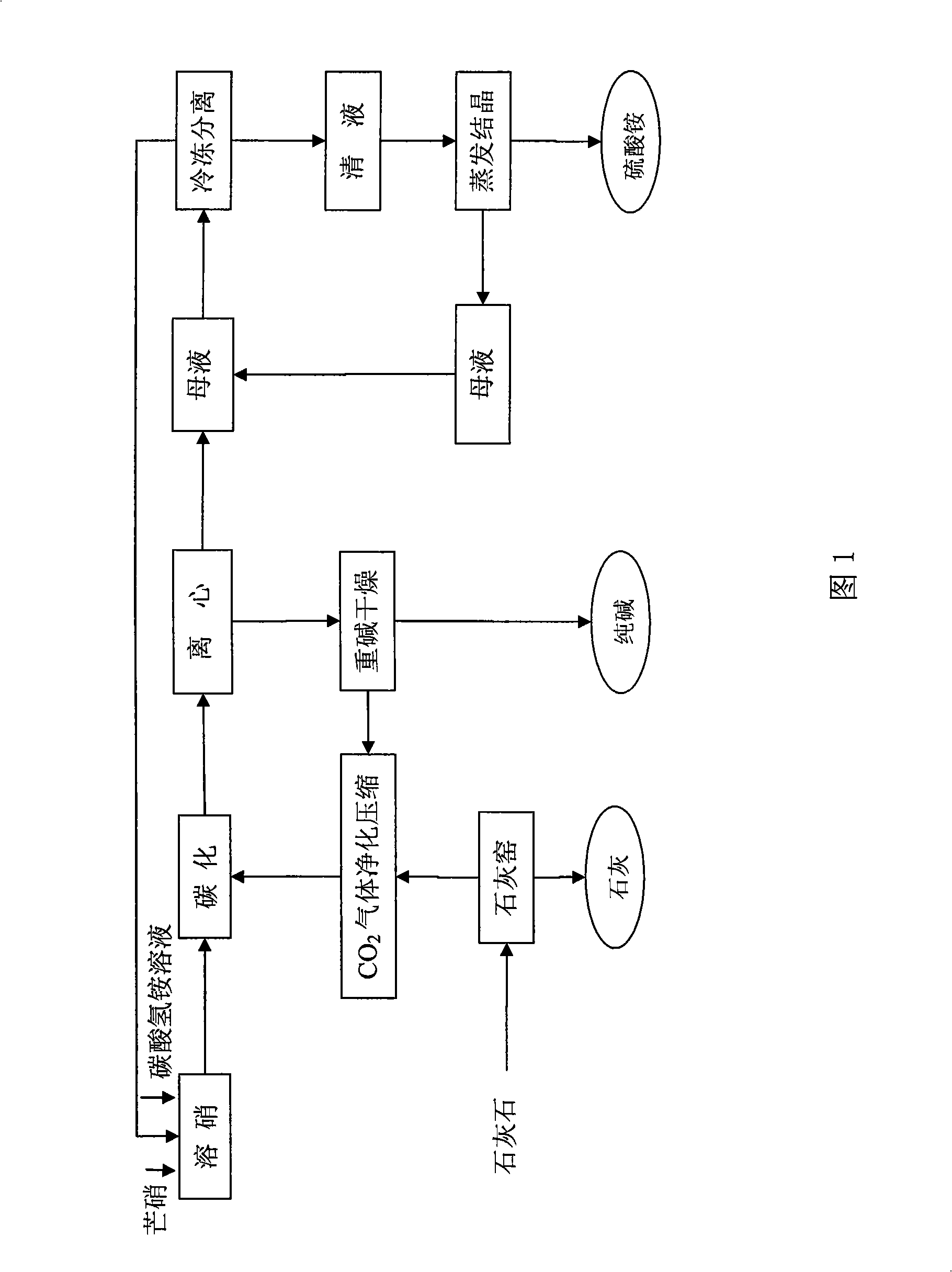

Method used

Image

Examples

Embodiment 1

[0029] A. Ammonia water carbonization process: configure the finished ammonia water with a concentration of 25% as a 100g / L solution and add it to the carbonization tower, and feed in a concentration of 25% CO 2 Gas carbonization for 2.5 hours, detection of NH 3 6.9%, CO 2 6.7%.

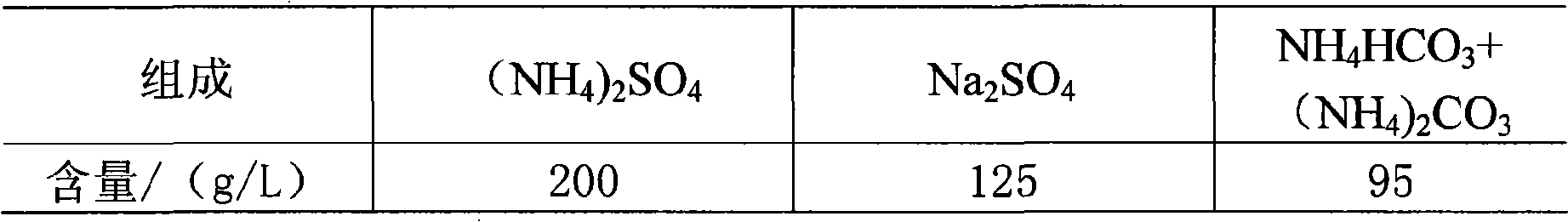

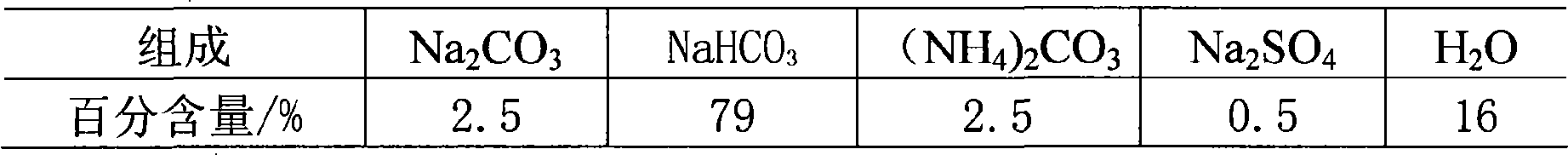

[0030] B. Nitrate dissolving process: Dissolve 100Kg of Glauber’s salt with a mass content of 85% in 300L of carbonized ammonia solution, filter and precipitate, wash with 50L of hot water, and the washing liquid composition is NH 3 12.5g / L, CO 2 14.6g / L and Na 2 SO 4 36g / L, the water content in the washed solids is 26%, the weight is 17.56Kg, and the clear liquid contains Na 2 SO 4 22.2%, the serum volume is 305L, the main component is Na 2 SO 4 260g / L, NH 3 83g / L, CO 2 92g / L, (NH 4 ) 2 SO 4 5.6g / L. After adding frozen salt, the solution is adjusted to a saturated solution of Glauber's salt, and its composition is: NH 3 83g / L, CO 2 110g / L and Na 2 SO 4 320g / L, (NH 4 ) 2 SO 4 8g / ...

Embodiment 2

[0057] A. Ammonia water carbonization process: configure the finished ammonia water with a concentration of 25% as a 105g / L solution and add it to the carbonization tower, and feed in a concentration of 35% CO 2 Gas carbonization for 6 hours, detection of NH 3 7.0%, CO 2 6.8%.

[0058] B. Nitrate-dissolving process: 100Kg of Glauber's salt with a mass content of 95% is dissolved in 300L of aqueous solution of ammonia carbonate, filtered and precipitated, washed with 50L of hot water, and after adding frozen salt, the solution is prepared as a saturated solution of Glauber's salt.

[0059] The detergent composition is NH 3 12.8g / L, CO 2 14.9g / L and Na 2 SO 4 39g / L, 26% water in the washed solids, 17.25Kg in weight, and Na in the supernatant 2 SO 4 22.7%, the serum volume is 305L, the main component is Na 2 SO 4 286g / L, NH 3 85g / L, CO 2 93g / L, (NH 4 ) 2 SO 4 5.9g / L. After adding frozen salt, the solution is adjusted to a saturated solution of Glauber's salt, and i...

Embodiment 3

[0082] Embodiment 3: repeat embodiment 1, have following difference,

[0083] A. Ammonia water carbonization process: directly dissolve ammonium bicarbonate to obtain NH 3 6.9~7.0% and CO 2 6.7-6.8% solution;

[0084] B. Nitrate dissolving process: directly dissolving Glauber's salt with a mass percent content of 85% in ammonium bicarbonate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com