Method of manufacturing tin indium oxide target material

A technology of indium tin oxide and its production method, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of high production cost, large processing volume, lack of oxygen atoms, etc., and achieve production efficiency and finished products The effect of increased rate, small shrinkage and deformation, and reduced manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ITO co-precipitation powder with an average particle size of 0.5 microns, wherein the content of tin oxide is 10%, and the content of indium oxide is 90wt% powder, and this is used as the main raw material to add 0.1% of bismuth oxide powder with an average particle size of 5 microns to form the raw material .

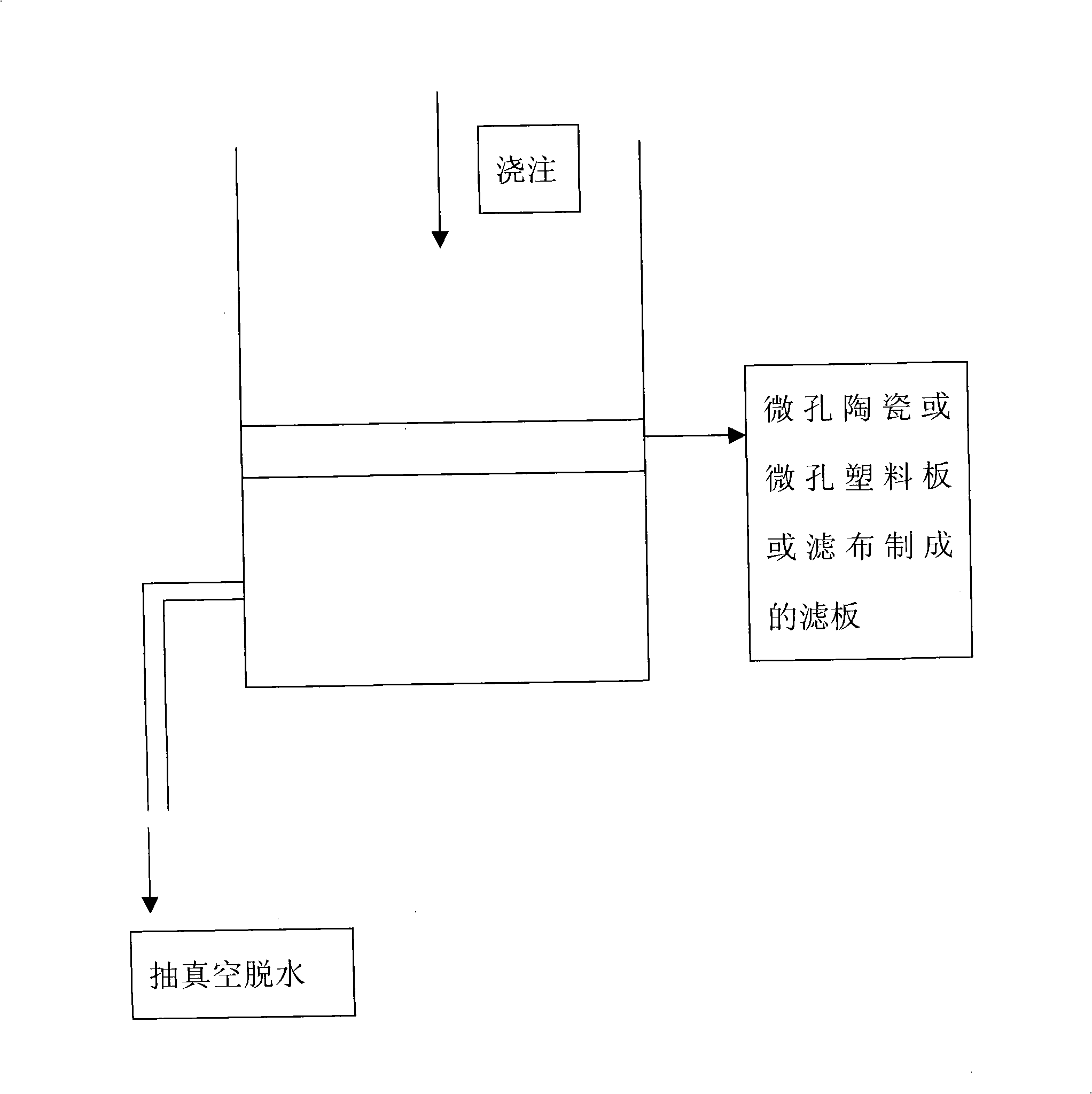

[0027] Fully dissolve pure water, methacrylamide monomer, and N-N'dimethylbisacrylamide at a ratio of 100:16:0.7 to form a premix, add 0.15% tetramethylammonium hydroxide as a dispersant, add The above-mentioned raw material powders are stirred and made into slurry. The solid phase content of the raw material powders in the slurry is 65%. The prepared slurry is poured into a ball mill, and zirconia balls are used as medium ball mills for more than 24 hours, and then 0.3% volume of Organic degassing agents such as n-butanol and 0.2wt‰ tetramethylethylenediamine catalyst and 0.04wt‰ ammonium persulfate initiator were stirred and degassed in a vacuum mixer for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com