Method of manufacturing fine helical nickel-carbon alloy material

A technology of micro-helical and nickel alloys, which is applied in the field of preparation of micro-helical carbon-nickel alloy materials, can solve the problems of low density, high specific strength, heat resistance, electrical and thermal conductivity, low magnetic loss, and carbon-nickel alloy materials that have not been reported. Problems, to achieve excellent mechanical properties and mechanical properties, good magnetic properties, strong interface binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

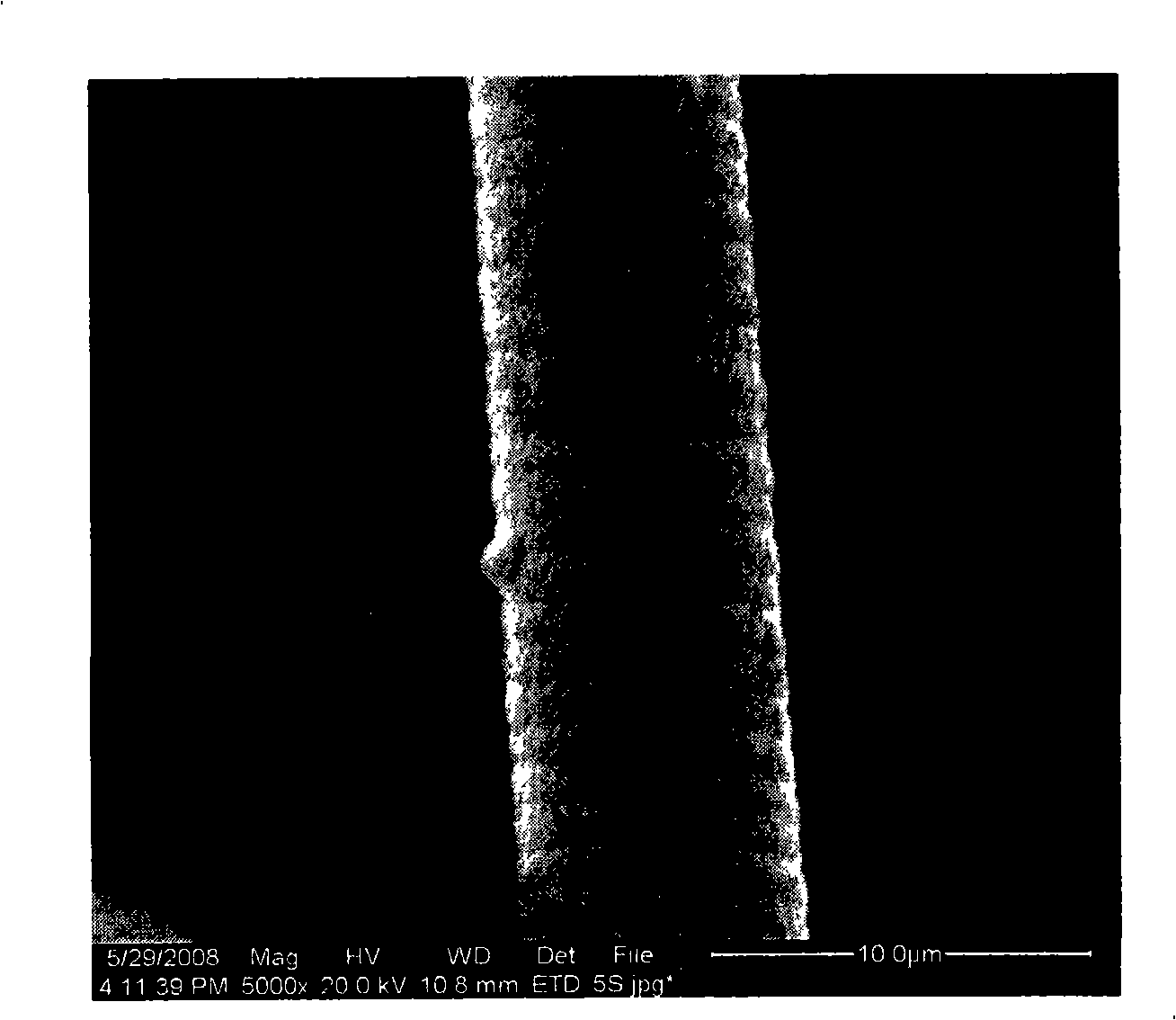

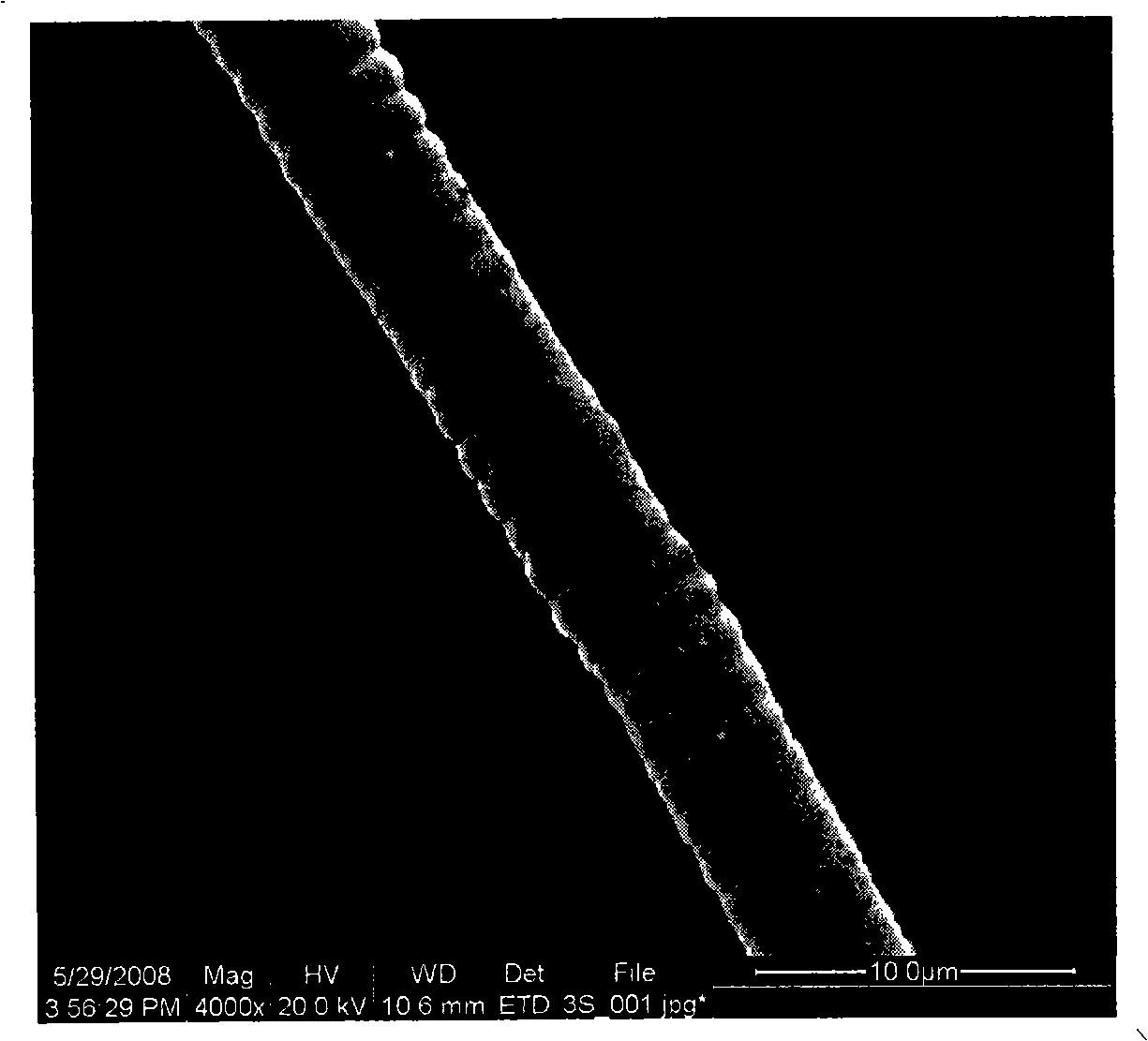

Embodiment 1

[0013] Using CVD method, nickel powder is used as catalyst, acetylene is used as carbon source, hydrogen is used as reducing gas, nitrogen is used as protective gas, react at 750°C for 4 hours, the average diameter of the prepared micro-helical carbon fiber coil is 3-7 μm, and the pitch is about 0 . The prepared original microhelical carbon fibers were ultrasonically dispersed, cleaned with acetone, and then roughened with mixed acid (sulfuric acid / nitric acid = 3:1 (v / v)) for 4 h, and then in SnCl 2 Sensitization treatment in hydrochloric acid solution, followed by PdCl 2 Activation treatment is carried out in hydrochloric acid solution; magnetic stirring is used for sensitization and activation treatment; after each step of treatment, the fiber must be cleaned to neutral with deionized water to avoid bringing impurities into the next treatment solution. Dry the activated microhelical carbon fibers at 50°C for use.

[0014] Configure the nickel solution according to the fol...

Embodiment 2

[0016] Using CVD method, nickel powder is used as catalyst, acetylene is used as carbon source, hydrogen is used as reducing gas, nitrogen is used as protective gas, react at 750°C for 4 hours, the average diameter of the prepared micro-helical carbon fiber coil is 3-7 μm, and the pitch is about 0 . The prepared original microhelical carbon fibers were ultrasonically dispersed, cleaned with acetone, and then roughened with mixed acid (sulfuric acid / nitric acid = 3:1 (v / v)) for 4 h, and then in SnCl 2 Sensitization treatment in hydrochloric acid solution, followed by PdCl 2 Activation treatment is carried out in hydrochloric acid solution; magnetic stirring is used for sensitization and activation treatment; after each step of treatment, the fiber must be cleaned to neutral with deionized water to avoid bringing impurities into the next treatment solution. Dry the activated microhelical carbon fibers at 50°C for use.

[0017] Configure the nickel solution according to the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com