Titanium oxide oil base nanofluid

A technology of nanofluid and titanium oxide, which is applied in the direction of base materials, petroleum industry, additives, etc., can solve the problems of difficult dispersion, restricting the wide application of nanofluid, and poor anti-sedimentation stability, and achieves simple and easy preparation process, The effect of low raw material price and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

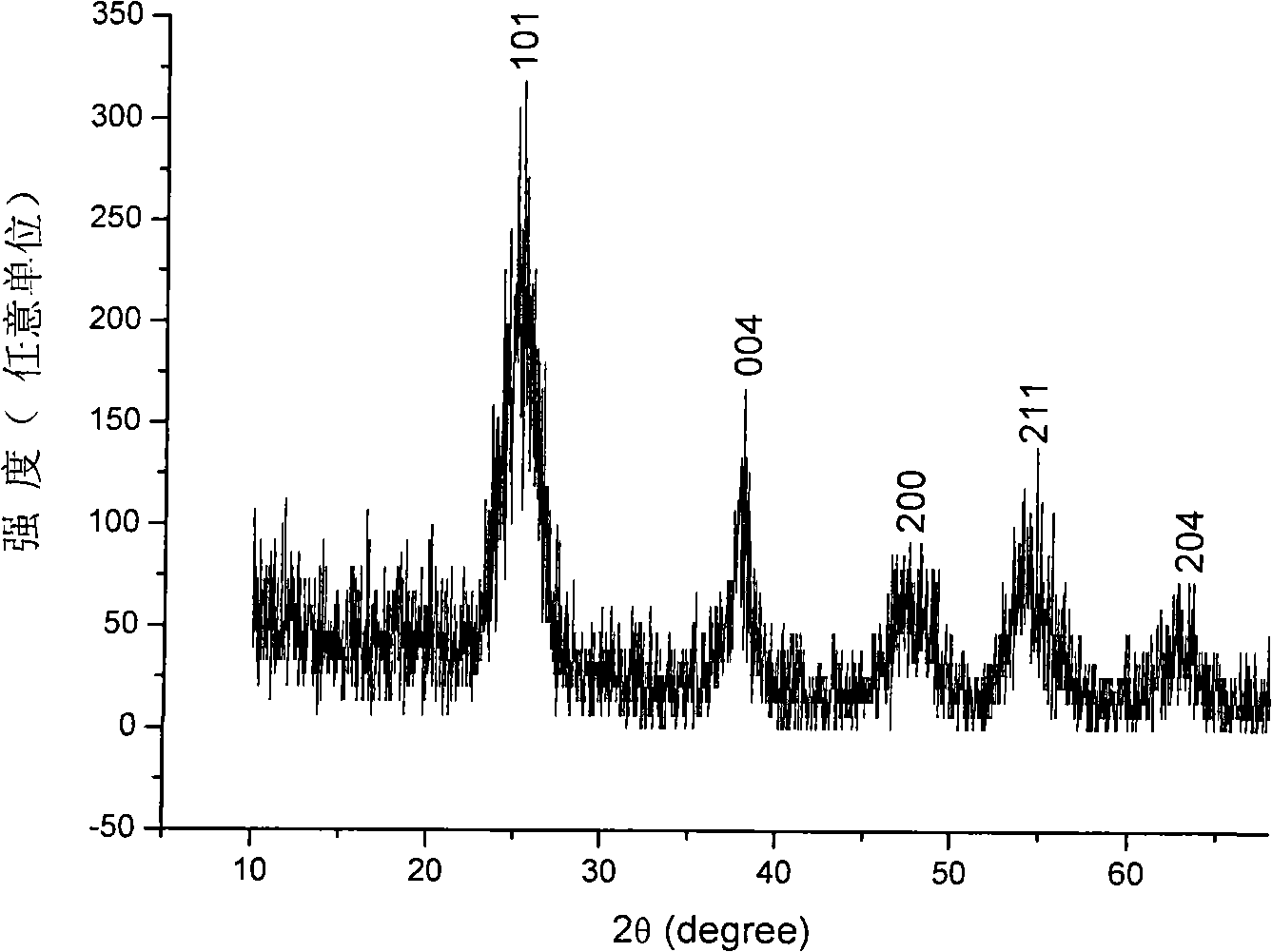

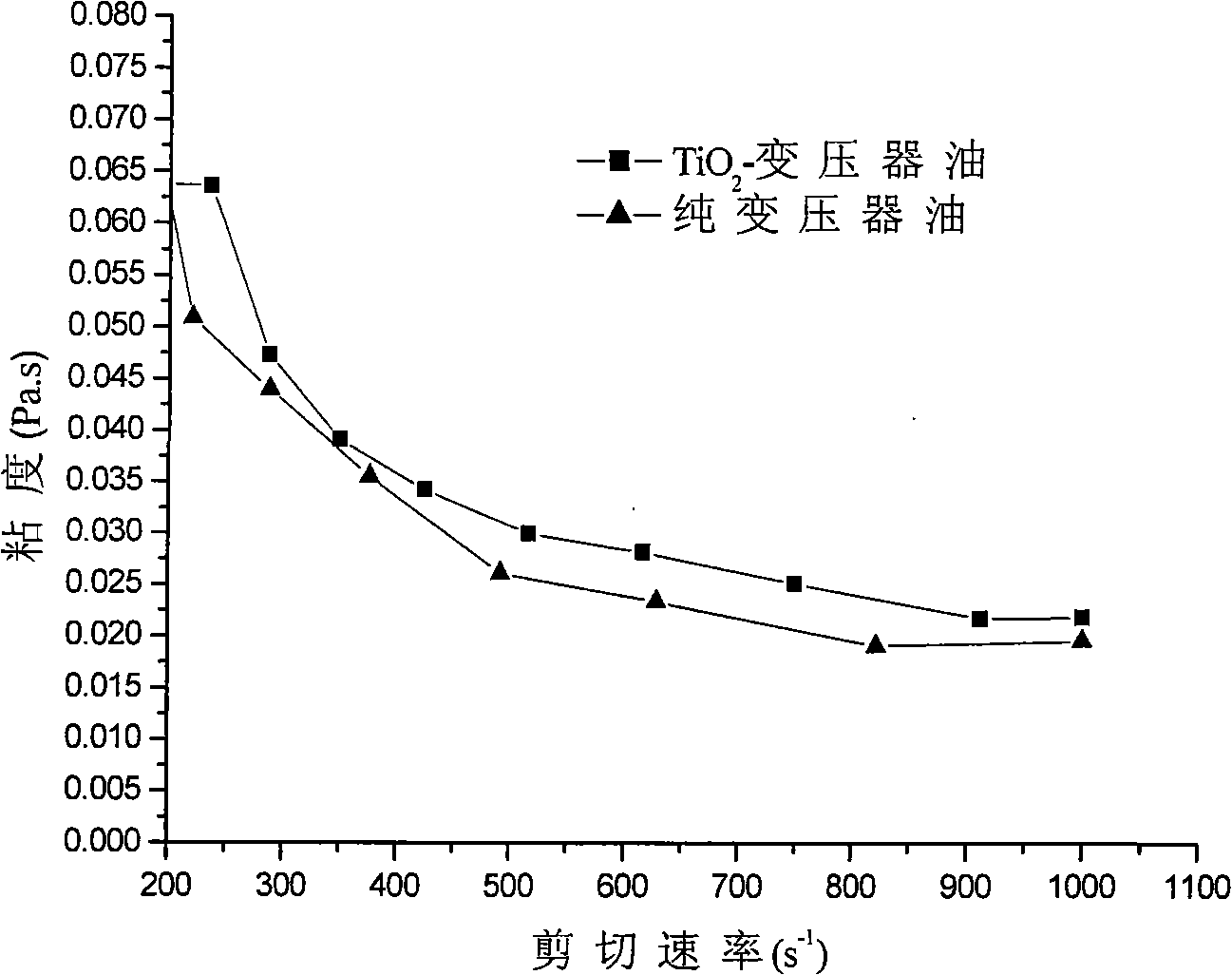

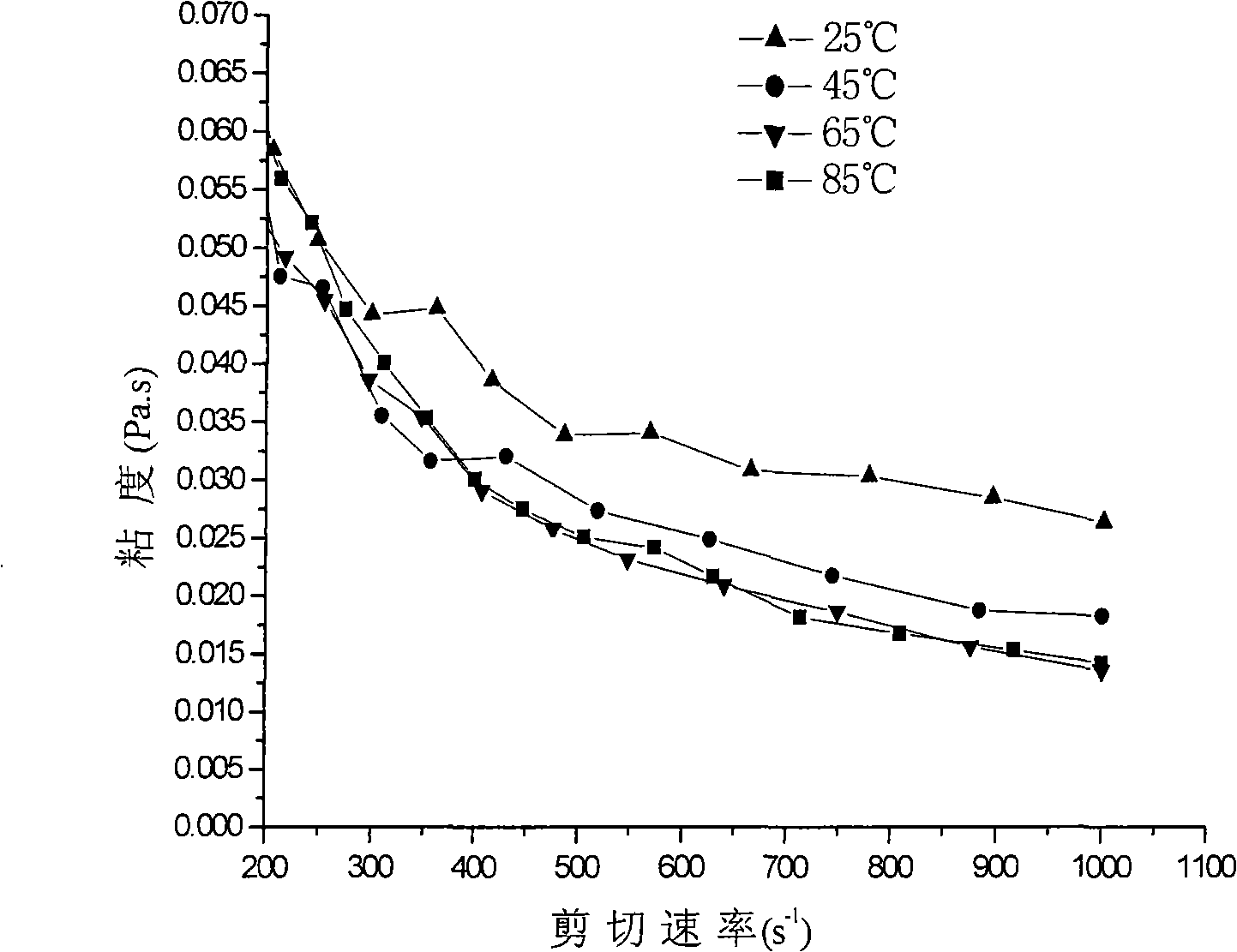

[0015] Embodiment one: (pure TiO 2 -transformer oil nanofluid)

[0016] Mix 14ml of oleic acid, 10ml of triethylamine, and 50ml of petroleum ether in a 250ml beaker, and stir magnetically at 40-50°C for 30min. Add 2ml of n-butyl titanate dropwise to the mixed solution while stirring vigorously, transfer it into a 100ml pressure melting bomb after 30min, and react at 150°C for 48h. Cool the pressure solution bomb to room temperature, and the obtained reddish-brown transparent TiO 2 Petroleum ether sol. To TiO 2 Add about 100ml of absolute ethanol to the petroleum ether sol, because the colloidal particles coagulate and white precipitates out, let stand, remove the supernatant, add 100ml of absolute ethanol to the beaker again, stir well and let stand again, remove the supernatant, Add absolute ethanol to the precipitate and stir thoroughly, filter with a funnel, disperse the wet filter cake in 50ml of transformer oil, grind it evenly, and magnetically stir at 50-60°C for 1 ...

Embodiment 2

[0017] Embodiment two: (pure TiO 2 -Liquid paraffin nanofluid)

[0018] Mix 14ml of oleic acid, 10ml of triethylamine, and 50ml of petroleum ether in a 250ml beaker, and stir magnetically at 40-50°C for 30min. While stirring, add 2ml of n-butyl titanate dropwise to the mixed solution, transfer it into a 100ml pressure melting bomb after 30min, and react at 150°C for 48h. Cool the pressure solution bomb to room temperature, and the obtained reddish-brown transparent TiO 2 Petroleum ether sol. To TiO 2 Add about 100ml of absolute ethanol to the petroleum ether sol, because the colloidal particles coagulate and white precipitates out, let stand, remove the supernatant, add 100ml of absolute ethanol to the beaker again, stir well and let stand again, remove the supernatant, Add absolute ethanol to the precipitate and stir thoroughly, filter with a funnel, disperse the wet filter cake in 50ml of liquid paraffin, grind it evenly, and magnetically stir at 50-60°C for 1 hour to ob...

Embodiment 3

[0019] Embodiment three: (doped with lanthanum TiO 2 -transformer oil nanofluid)

[0020] 14ml oleic acid, 10ml triethylamine and 3%-10% LaCl 3 ·xH 2 Mix O in a 250ml beaker and stir magnetically at 40-50°C until dissolved, then add 50ml of petroleum ether and stir evenly. Add 2ml of n-butyl titanate dropwise to the mixed solution, stir for 30min, then transfer to a 100ml pressure melting bomb, and react at 150°C for 48h. Cool the pressure solution bomb to room temperature, and the obtained light yellow transparent lanthanum-doped TiO 2 Petroleum ether sol. To TiO 2 Add about 100ml of absolute ethanol to the petroleum ether sol, because the colloidal particles coagulate and white precipitates out, let stand, remove the supernatant, add 100ml of absolute ethanol to the beaker again, stir well and let stand again, remove the supernatant, Add absolute ethanol to the precipitate and stir thoroughly, filter with a funnel, disperse the wet filter cake in 50ml of transformer oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com