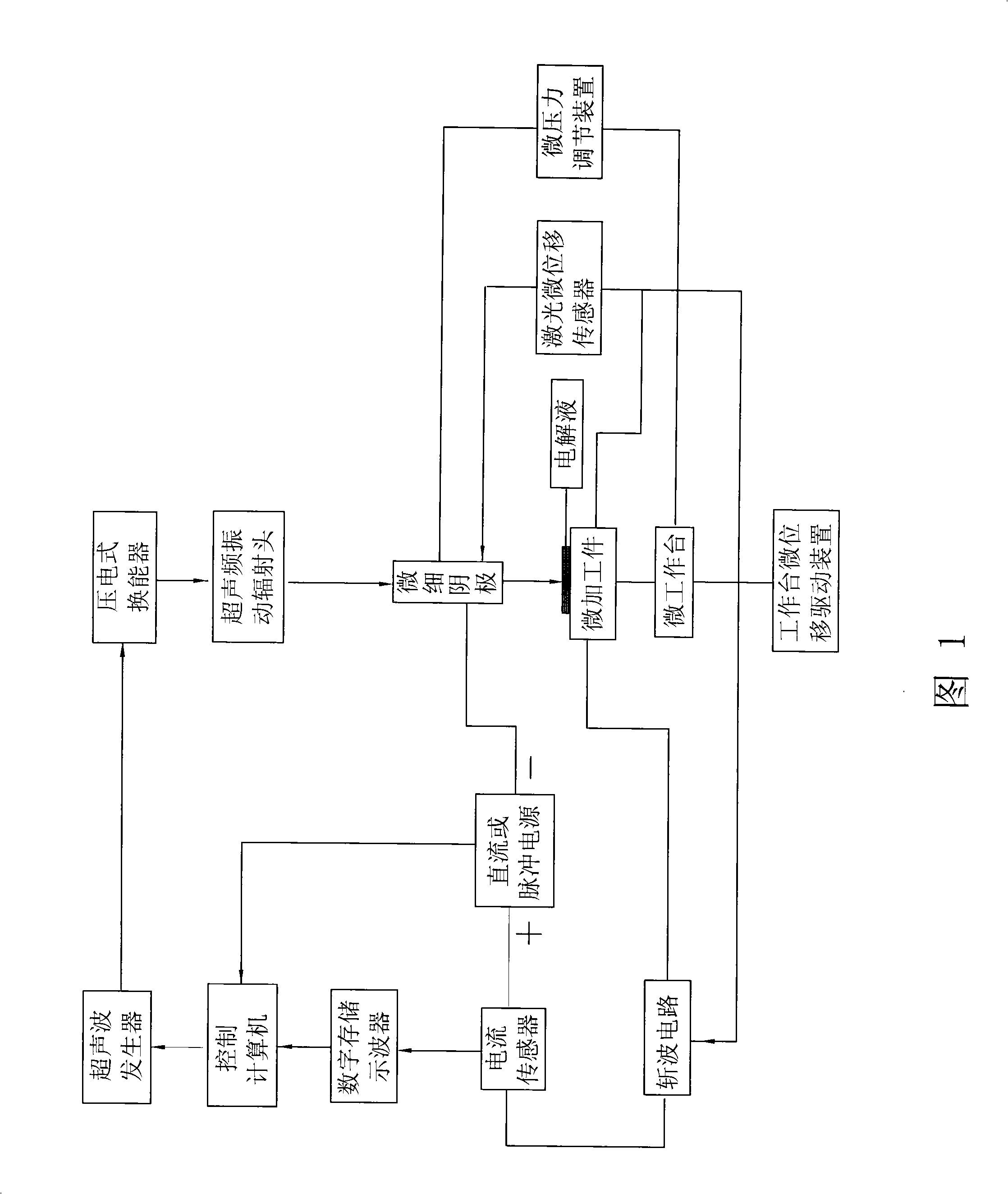

Composite synchronous superaudio vibrating micro electrolytic machining method

A technology of micro-electrolysis and processing methods, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., and can solve the problems of inevitable tool cathode wear, damage to cathode and workpiece, and limitation of cathode service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

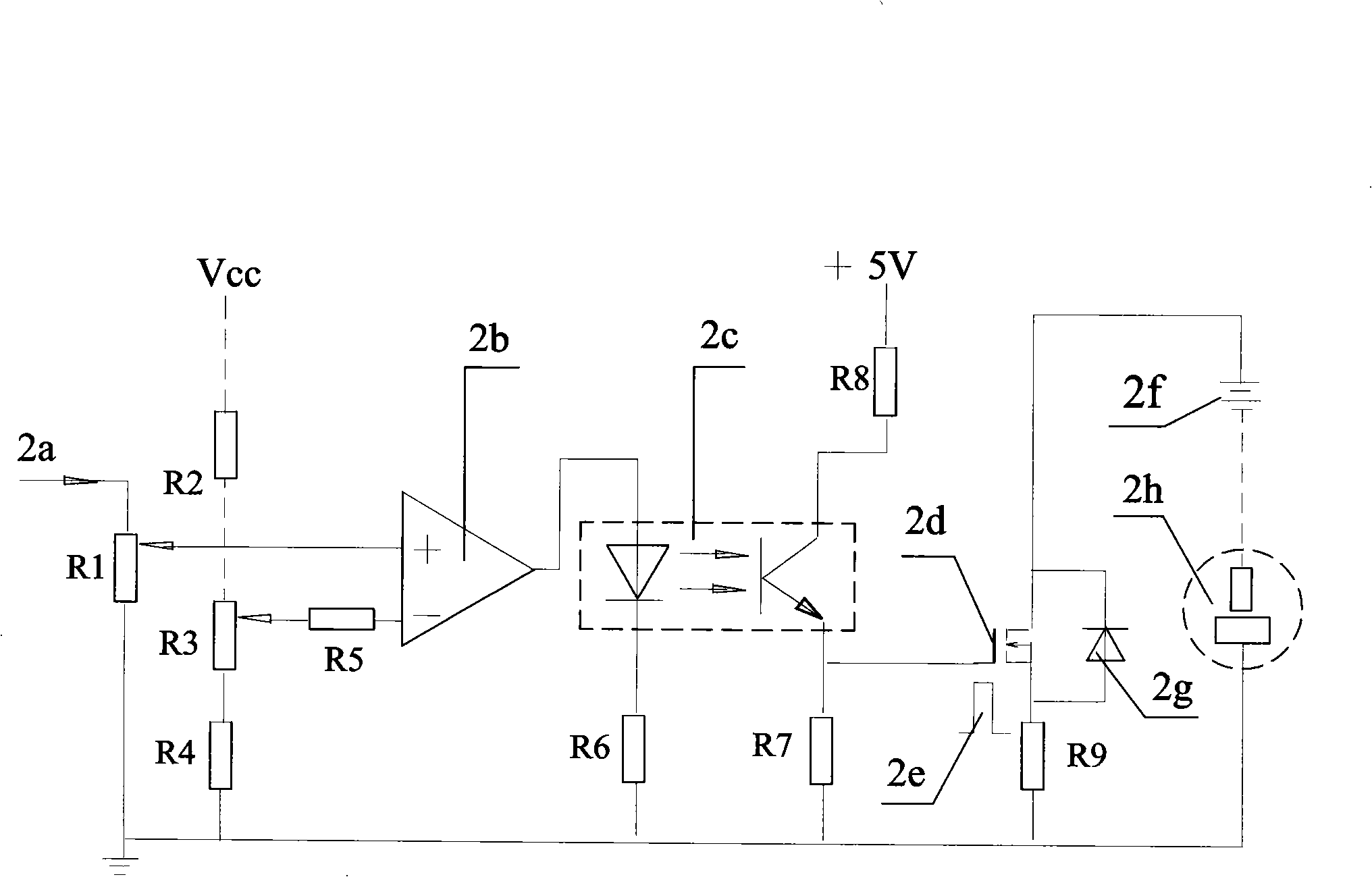

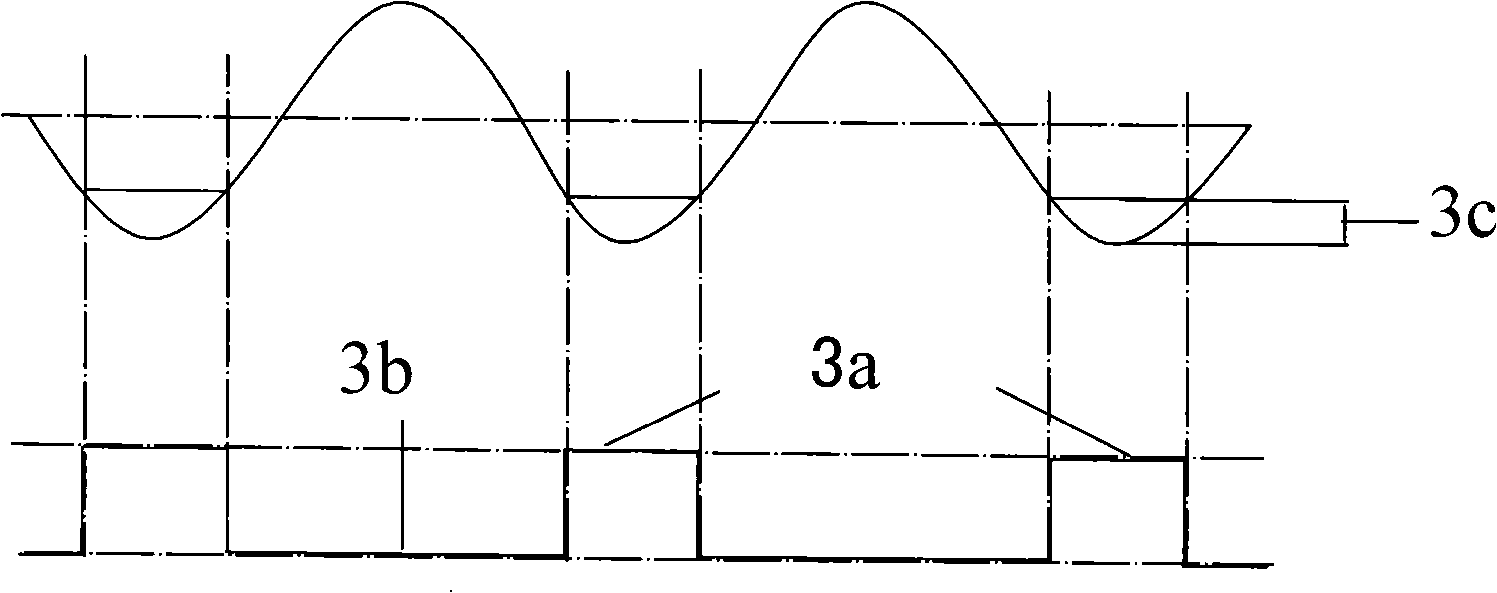

Method used

Image

Examples

example 1

[0052] Example 1: Square micro-groove composite micro-electrolytic machining

[0053] DC electrolysis voltage 1V ~ 4V, system ultrasonic frequency vibration resonance frequency 19.63KHz, ultrasonic power 60W, ultrasonic amplitude 0.05mm, abrasive 1600 mesh silicon carbide, electrolyte 5% sodium nitrate aqueous solution, the contact between the workpiece and the fine cathode is static Pressure 2.0N. Using a square cathode with a side length of 1 mm to conduct electrolytic composite ultrasonic vibration machining tests on cemented carbide YG8 with different DC voltages, the machining time is 3 minutes. As the machining voltage increases, the depth of the square groove on the surface of the workpiece gradually increases; when the voltage exceeds 3V, the increase is obvious. However, when the voltage increases, the electrolysis effect is enhanced, the processing localization is weakened, the consistency of material removal is deteriorated, and the processing size accuracy is deter...

example 2

[0056] Example 2: Composite electrolytic micromachining of square-conical array micro-pits

[0057] Pulse power supply voltage amplitude 0V (corresponding to single ultrasonic processing), 1V, 2V, 4V, frequency 5000Hz, duty ratio 4:6, system ultrasonic vibration resonance frequency 20.32KHz, ultrasonic power 45W, ultrasonic amplitude 0.03mm, electrolyte is 5% sodium nitrate aqueous solution, adding boron carbide W10 micropowder in the sodium nitrate aqueous solution, the contact static pressure between the workpiece and the fine cathode is 1.60N, and the processing time is 3 minutes.

[0058] The depth and efficiency of the square-conical micro-pit in the composite ultrasonic frequency vibration micro-electrolytic machining are significantly higher than those of the single-ultrasonic machining, and the processing efficiency increases with the increase of the voltage. 2V voltage electrolytic compound machining accuracy and surface quality are the best.

[0059] When processing...

example 3

[0060] Example 3: Electrolytic compound machining of cemented carbide YBD151 micro-gear

[0061] Pulse power supply voltage amplitude 2V, frequency 5000Hz, duty ratio 4:6, system ultrasonic vibration resonance frequency 20.12KHz, ultrasonic power 45W, ultrasonic amplitude 0.03mm, contact static pressure between workpiece and fine cathode is 1.60N, electrolysis The solution is 5% sodium nitrate aqueous solution, and boron carbide W10 micropowder is added into the sodium nitrate aqueous solution, and the processing time is 3 minutes.

[0062] Using a micro-cathode with internally toothed holes, the involute micro-gear with a modulus of 0.25mm and a pressure angle of 20° is nested on the cemented carbide YBD151 material with a high wear-resistant matrix and a composite wear-resistant coating. The processed micro-gear The thickness is 0.30mm, the involute tooth shape accuracy can reach ±0.001mm, and the tooth surface roughness Ra is 0.16μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com