High efficiency energy-conserving barrier diaphragm capacitance deionization device

A capacitive deionization and energy-saving technology, applied in the direction of ion exchange water/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems affecting the electrode's electric adsorption capacity, achieve response speed, reusability, improve performance, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

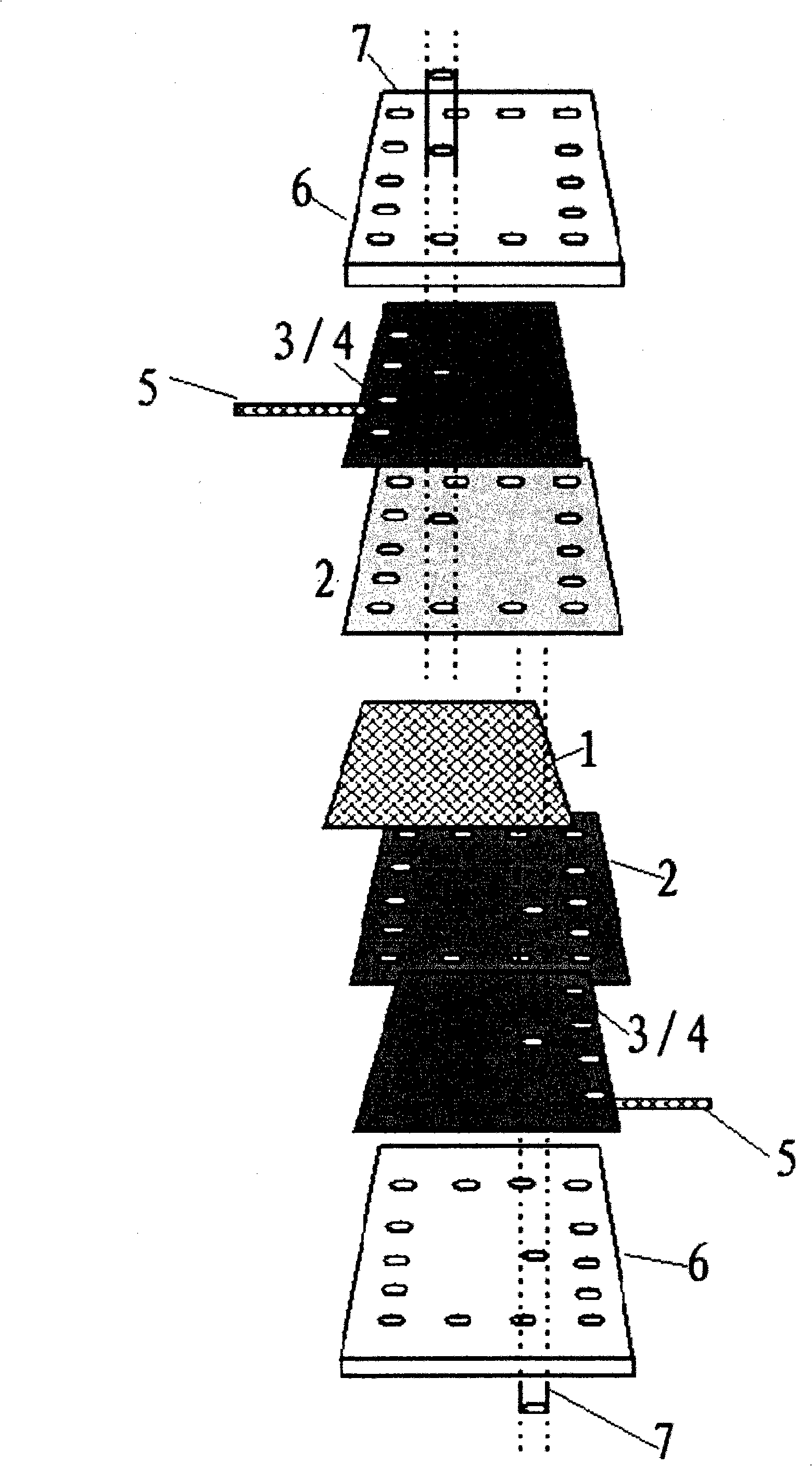

[0033] A diaphragm deionization capacitor unit, using a 100mm×100mm square graphite sheet as the conductive substrate 4, the thickness of the graphite sheet is 0.3mm, and a hole with a diameter of 6mm is drilled on the surface to allow water to pass through, and the surface of the graphite sheet is cleaned with acetone, Then prepare a layer of nickel metal catalyst layer on its surface by magnetron sputtering, and then use low-pressure chemical vapor deposition equipment to grow carbon nanotube-carbon fiber film on its surface as electrode 3, and the flow rates of acetylene and hydrogen are respectively 40sccm and 200sccm, The growth temperature is 550°C, and the growth time is 30 minutes;

[0034] The electrode lead wire 5 is made of carbon fiber wire; polypropylene cloth is used as the separator 1 with a thickness of 0.2mm; the supporting plate 6 is a plexiglass plate with a thickness of 5mm;

Embodiment 2

[0036] A diaphragm deionization capacitor unit, the electrode is 100mm × 200mm carbon airgel, the thickness is 0.5mm, and its surface is drilled with holes with a diameter of 8mm to allow water to pass through. The carbon airgel is prepared by the following method: Hydroquinone and formaldehyde are mixed at a molar ratio of 1:2, and secondary deionized water is added as a solvent and its mass percentage is adjusted, and Na 2 CO 3 As a catalyst, stir well to make the solution evenly mixed, move the mixed solution into a closed container, place it at room temperature for one day, then put it into a constant temperature box, and react at (85±3)°C for several days to generate red RF gas gel. Cut the airgel into a column, soak it in a suitable organic solvent for several hours, and change the organic solvent several times, so as to completely replace the water in the airgel. RF aerogels with continuous network structure were obtained by drying the soaked aerogels in the air for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com