Trimebutine or its salt sustained release capsules and preparation method thereof

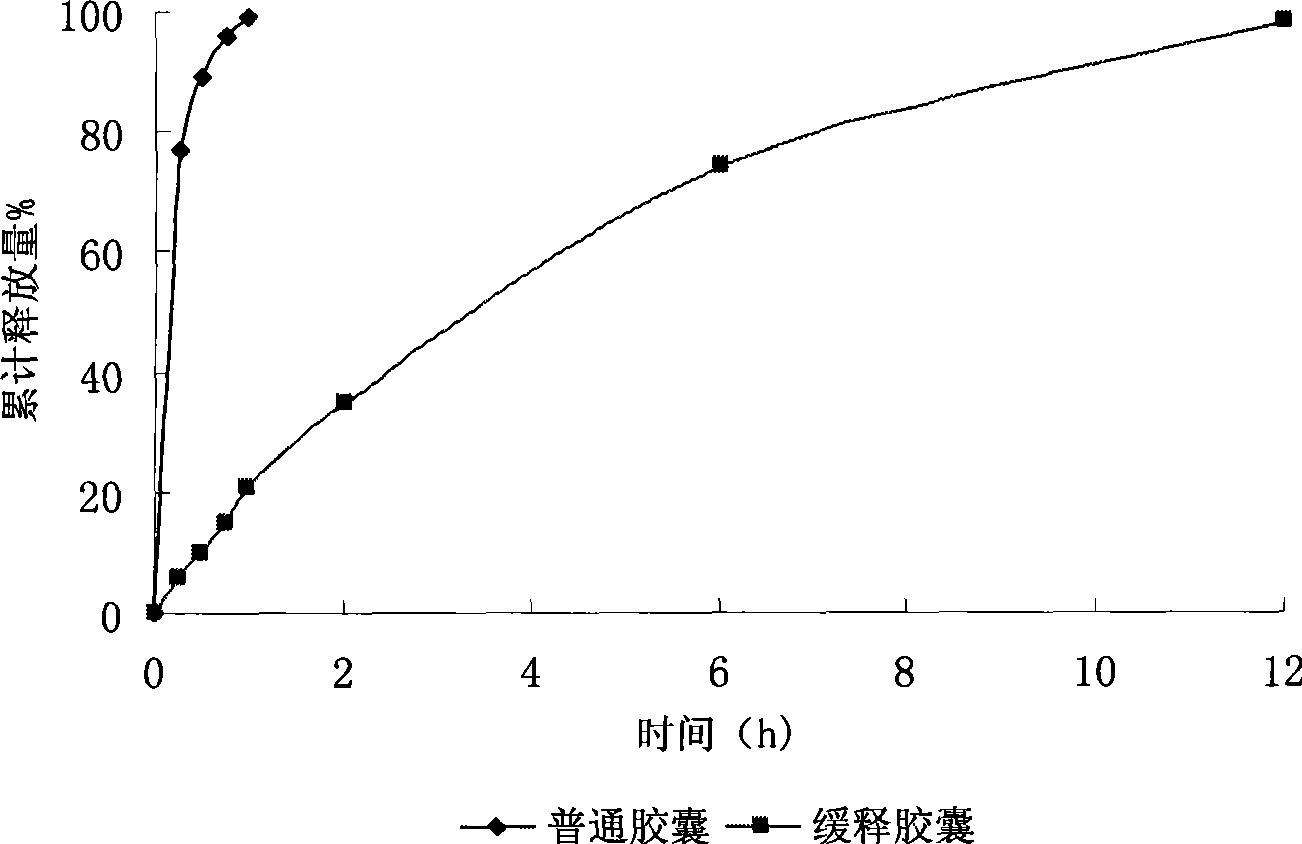

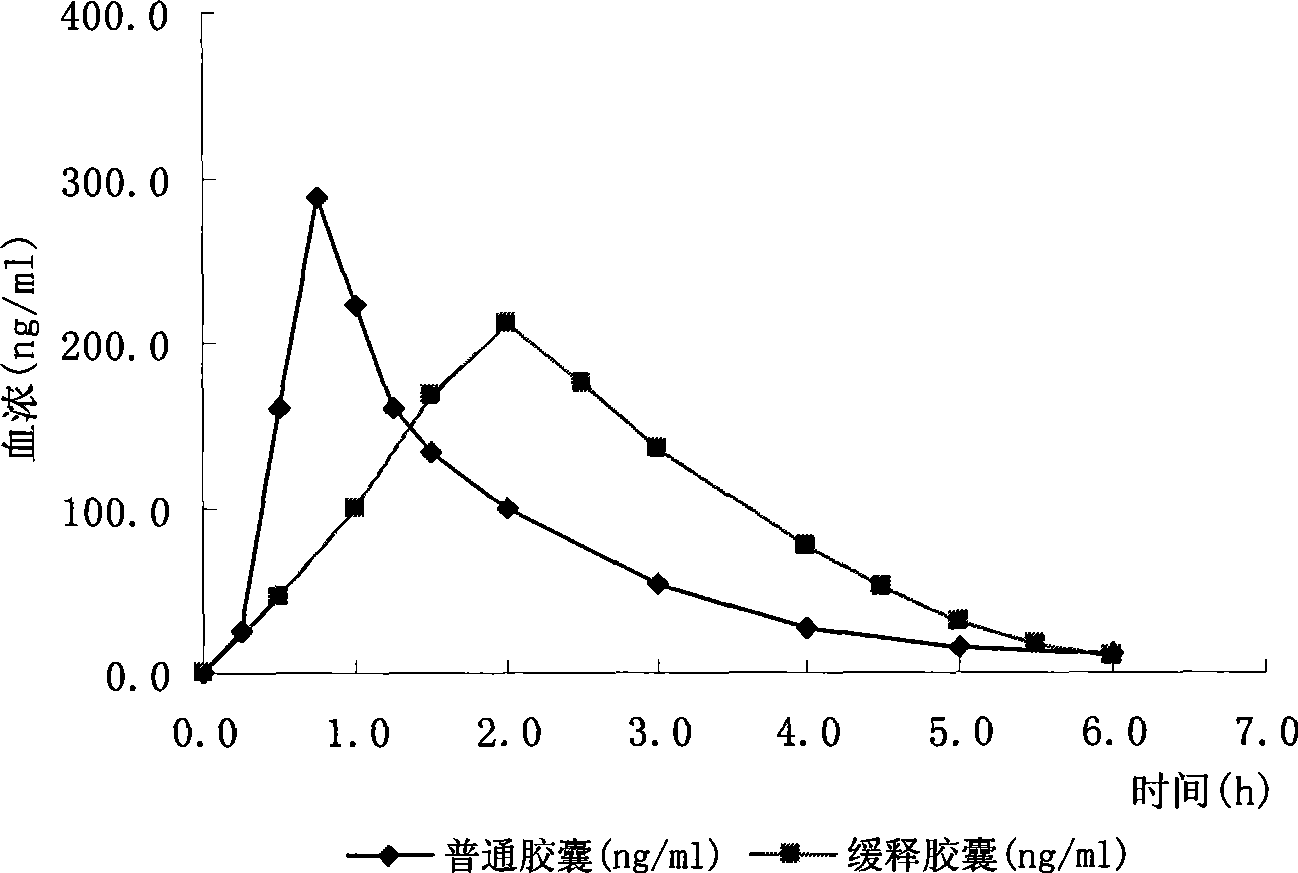

A technology for sustained-release capsules and pill cores, applied in the field of trimebutine or its salt sustained-release capsules and its preparation, capable of solving problems such as no sustained-release preparations on the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1: the preparation of trimebutine maleate sustained-release capsules

[0102] Trimebutine Maleate 150g

[0103] Ball core 60g

[0104] Microcrystalline Cellulose 150g

[0105] Hypromellose 8g

[0106] Acrylic resin RS30D:RL30D=10:1 180g

[0107] (Equivalent to 54g of acrylic polymer without solvent)

[0108] Triethyl citrate 6g

[0110] 200ml of water;

[0111] The preparation method of the ball core is as follows: take microcrystalline cellulose fine powder in the centrifugal chamber and the powder supply chamber of the centrifugal granulator, use 3% hydroxypropyl methylcellulose as the binder, and the speed of the main machine is 150r / min~ 180r / min, blast flow rate 8L / min~10L / min, jet pressure 0.6Mpa~0.8MPa, jet flow rate 8L / min~10L / min, large flow spraying in the first 2 minutes, spray pump rotation speed is 70r / min min to 90r / min, then adjust to a medium-speed spraying flow rate, adjust the spray pump rotation speed to 30r...

Embodiment 2

[0113] Embodiment 2: the preparation of trimebutine maleate sustained-release capsules

[0114] Trimebutine Maleate 180g

[0115] Ball core 70g

[0116] Dextrin 110g

[0117] Carboxymethylcellulose 6g

[0118] Acrylic RS30D 36g

[0119] (Equivalent to 10.8g of acrylic acid polymer except the solvent)

[0120] Polyethylene glycol 6000 4.3g

[0121] Talc powder 6g

[0122] 50ml of water;

[0123] Wherein the preparation method of the ball core is: take the dextrin in the centrifugal chamber and the powder supply chamber of the centrifugal granulator, use 2% sodium carboxymethyl cellulose aqueous solution as the binder, and the speed of the main machine is 150r / min~180r / min, Blast flow rate is 8L / min~10L / min, jet pressure is 0.6Mpa~0.8MPa, jet flow rate is 8L / min~10L / min, the first 2 minutes is large flow spraying, and the rotation speed of spraying pump is 70r / min~90r / min, then adjust to medium-speed spraying flow rate, adjust the spray pump rotation number to 30r / min-5...

Embodiment 3

[0125] Embodiment 3: the preparation of trimebutine maleate sustained-release capsules

[0126] Trimebutine Maleate 130g

[0127] Ball core 90g

[0128] Lactose 140g

[0129] Povidone 6g

[0130] Acrylic resin RS100:RL100=9:1 36g

[0131] Triethyl citrate 3.6g

[0132] Talc powder 9g

[0133] 95% ethanol 300ml;

[0134]The preparation method of the ball core is as follows: take the lactose fine powder in the centrifugal chamber and the powder supply chamber of the centrifugal granulator, use 2% povidone aqueous solution as the binder, the speed of the main machine is 150r / min~180r / min, and the air blast The flow rate is 8L / min~10L / min, the jet pressure is 0.6Mpa~0.8MPa, the jet flow rate is 8L / min~10L / min, the first 2 minutes are large flow spraying, and the rotation speed of the spraying pump is 70r / min~90r / min. Then adjust the spray flow rate to medium speed, adjust the spray pump rotation speed to 30r / min-50r / min, continue to operate for 4 minutes, and then gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com