Triazines cross-linking compounds, preparation method and application thereof

A technology of cross-linking compounds and triazines, which is applied in the field of triazine cross-linking compounds and their preparation, can solve the problems of insurmountable disposal of waste solvents and corrosive hydrogen chloride, highly corrosive waste solvents, complicated process, etc. Achieve the effects of shortening the production cycle, simplifying the process flow, and making the preparation process simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

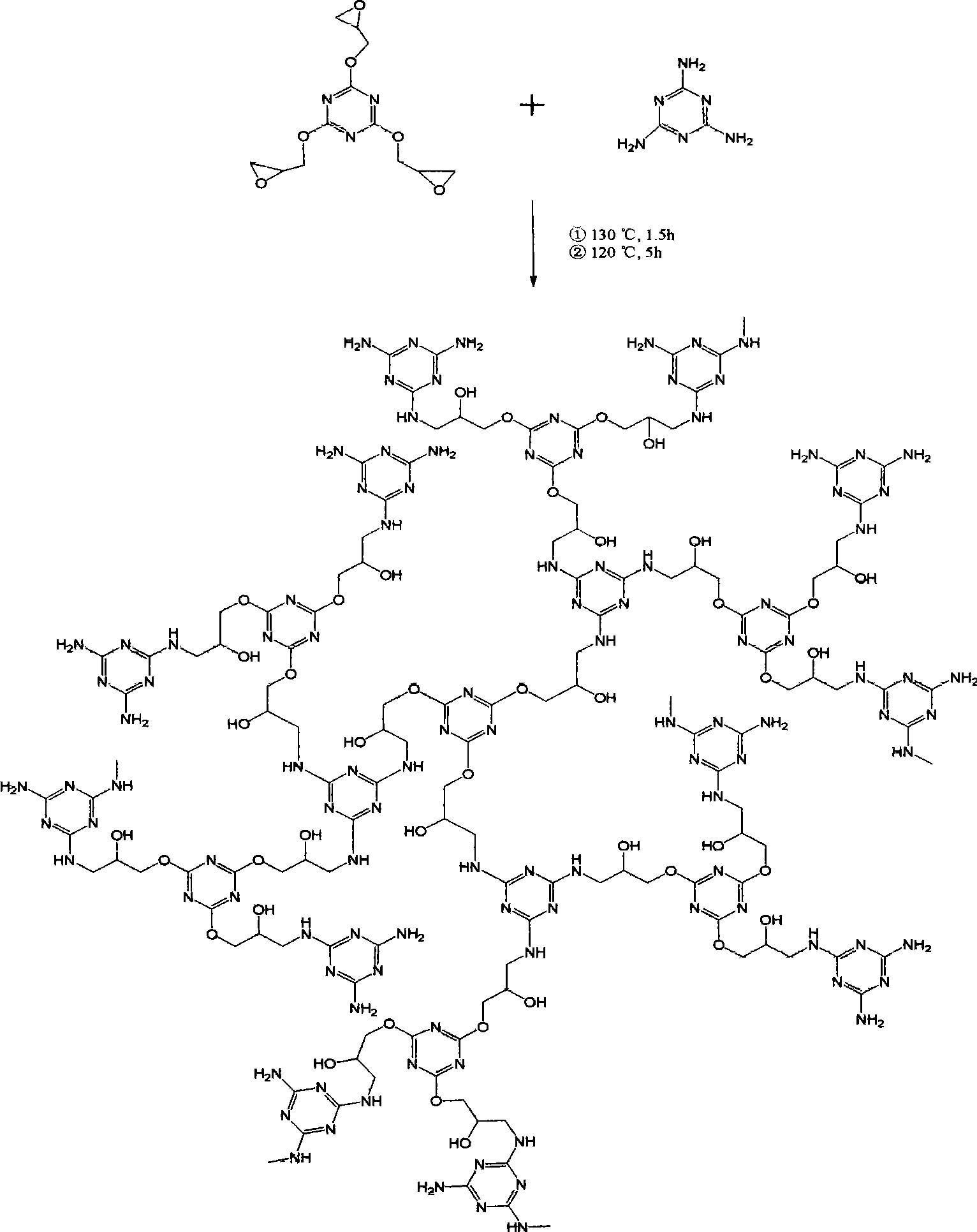

Method used

Image

Examples

Embodiment 1

[0027] Set the temperature of the Rheomix 3000 HAAKE rheometer to 130°C, and when the temperature reaches the set value, turn on the rotor at a speed of 60 rpm. The triglycidyl isocyanurate of 223.0 grams (0.75 moles) is put into the rheometer chamber, after the triglycidyl isocyanurate is completely melted, the melamine of 94.6 grams (0.75 moles) is added in three times, at 5 Minutes added. After 20 minutes of reaction, the torque of the rotor begins to increase slowly. After 100 minutes of continuous reaction, when the torque reaches 60N.m, take out the white paste material, cool it down to 80°C, and then put it into a blast drying oven at 130°C. Medium ripening for 5h. After the cured product is cooled to room temperature, it is pulverized by a high-speed pulverizer, then ground into a fine powder by a planetary ball mill, and passed through a 200-mesh filter sieve for later use.

[0028] Elemental analysis calcd for C 15 h 21 N 9 o 6 : C 42.55%, N 29.79%, H 4.96%, fo...

Embodiment 2

[0030] Set the temperature of the Rheomix 3000 HAAKE rheometer to 130°C, and when the temperature reaches the set value, turn on the rotor at a speed of 60 rpm. The triglycidyl isocyanurate of 148.7 grams (0.5 mole) is put into the rheometer chamber, after the triglycidyl isocyanurate melts completely, the melamine of 126.1 grams (1.0 mole) is added in three times, at 5 Minutes added. After 20 minutes of reaction, the torque of the rotor begins to increase slowly. After 90 minutes of continuous reaction, when the torque reaches 60N.m, take out the white paste material, cool it down to 50°C, and then put it into a blast drying oven at 130°C. Medium ripening for 5 hours. After the cured product is cooled to room temperature, it is pulverized by a high-speed pulverizer, then ground into a fine powder by a planetary ball mill, and passed through a 200-mesh filter sieve for later use.

[0031] Elemental analysis calcd for C 18 h 27 N 15 o 6 : C 39.34%, N 38.25%, H 4.92%, foun...

Embodiment 3

[0033] Set the temperature of the melting section and the homogenizing section of the Φ20 twin-screw extruder to 150°C, the screw speed is 15 rpm, and 1189 grams (4 moles) of triglycidyl isocyanurate are mixed with 1261 grams of melamine (10 moles). After uniformity, put it into the feeding cylinder. The extruded material is hot-cut into pellets. After the pellets are cooled to about 20°C, put all the obtained pellets back into the feeding barrel for the second extrusion, pelletizing and cooling, and repeat this process twice. Finally, put the obtained pellets into a blast drying oven at 140°C for aging for 6 hours. After cooling to room temperature, the cured product is pulverized by a high-speed pulverizer, then ground into a fine powder with a planetary ball mill, and passed through a 200-mesh filter sieve. spare.

[0034] Elemental analysis calcd for C19.5 h 30 N 18 o 6 : C 38.23%, N 41.18%, H 4.90%, found C37.95%, N 40.23%, H 4.88%; decomposition temperature (1% weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com