Apparatus for preparing carbonic anhydride with high temperature garbage burning

A carbon dioxide and garbage technology, applied in the fields of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of toxic and harmful gases of dioxin, the difficulty of complete combustion of garbage organic matter, and the loss of heat, so as to reduce the greenhouse gas effect and save energy. Auxiliary fuel, the effect of achieving zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail by the following examples.

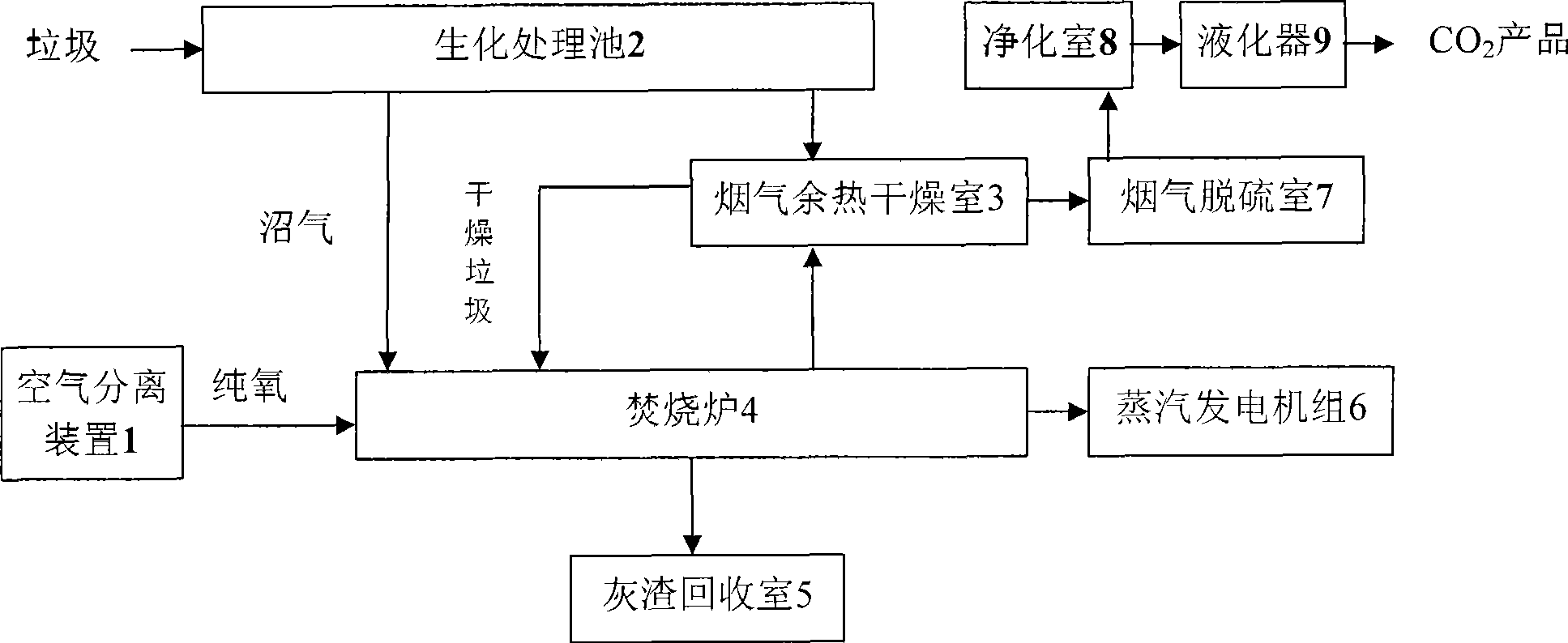

[0014] see figure 1 As shown, the device for producing carbon dioxide by high-temperature incineration of garbage consists of a flue gas waste heat drying chamber 3, an incinerator 4, a steam generator set 6, an air separation device 1, a biochemical treatment pool 2, an ash recovery chamber 5, a flue gas desulfurization chamber 7, Clean room 8, liquefier 9 components. The garbage is compressed and packaged and transported to the garbage incineration plant, stored in the biochemical treatment pool 2, and undergoes biochemical treatment after a turnaround period of 3-7 days. The biochemically treated garbage is sent to the flue gas waste heat drying chamber 3, and dried Send in the incinerator 4 again again, utilize the methane produced by the biochemical treatment tank 2 to pass into the rubbish after igniting the drying in the incinerator 4, meanwhile, the pure oxygen produced by the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com