Thermoplastic resin composition

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition, can solve the problems of quality reduction, imperfection, unavoidable impact resistance imparting effect, etc., and achieve the effect of high impact resistance and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The general preparation method of the above-mentioned graft copolymer is specifically described in, for example, JP-A-2002-363372, JP-A-2003-119396, JP-9-286830, etc. limited to them.

[0052] As the monomer that can be used in the graft copolymer (B) of the present invention, for example, a monomer composition obtained by mixing one or two or more monomers selected from the following monomer groups can be used.

[0053] Examples of the aforementioned monomer group include, for example,

[0054] (1) Methyl acrylate, ethyl acrylate, butyl acrylate, 2-ethylhexyl acrylate, octyl acrylate, dodecyl acrylate, octadecyl acrylate, behenyl acrylate, etc. Alkyl acrylates having an alkyl group, alkyl acrylates having a hydroxyl group such as 4-hydroxybutyl acrylate or alkyl acrylates having an alkoxy group,

[0055] (2) Methyl methacrylate, ethyl methacrylate, butyl methacrylate, 2-ethylhexyl methacrylate, dodecyl methacrylate, octadecyl methacrylate, Alkyl methacrylates having...

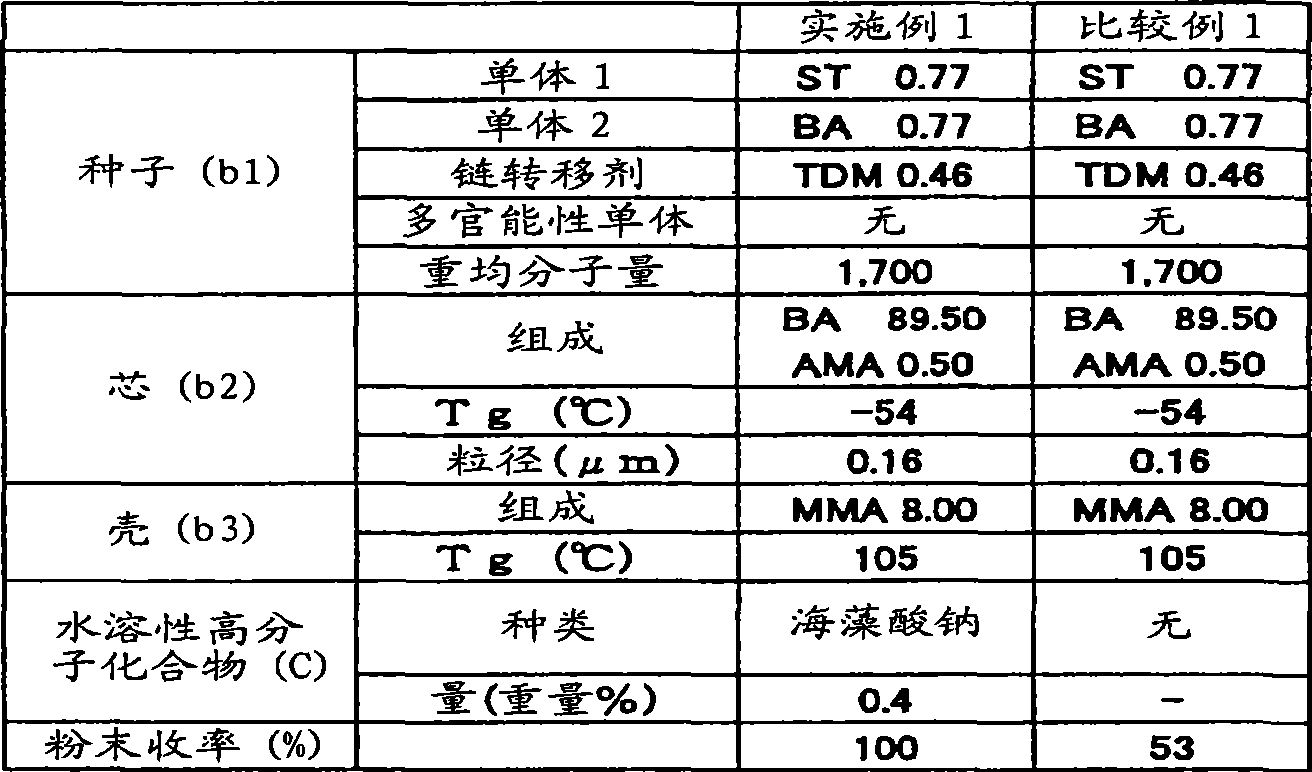

Embodiment 1

[0087] (Preparation of graft copolymer X)

[0088]

[0089]After adding 350 parts by weight of deionized water and 5 parts by weight of sodium oleate into a glass reactor with a thermometer, a stirrer, a reflux cooler, a nitrogen flow inlet, a monomer addition device and an emulsifier addition device, stir in a nitrogen gas flow while raising the temperature to 50°C. Next, through the above adding device, add a part of the monomer mixture for the seed (b1), namely 3.85 parts by weight of butyl acrylate (hereinafter also referred to as BA), 3.85 parts by weight of styrene (hereinafter also referred to as ST) and as chain transfer agent The mixture of 2.30 parts by weight of tert-dodecyl mercaptan (hereinafter also referred to as TDM) and 0.02 parts by weight of cumene hydroperoxide, further added 0.01 parts by weight of disodium edetate and ferrous sulfate after 10 minutes A mixed solution obtained by dissolving 0.005 part by weight of 7-hydrate salt in 5 parts by weight of ...

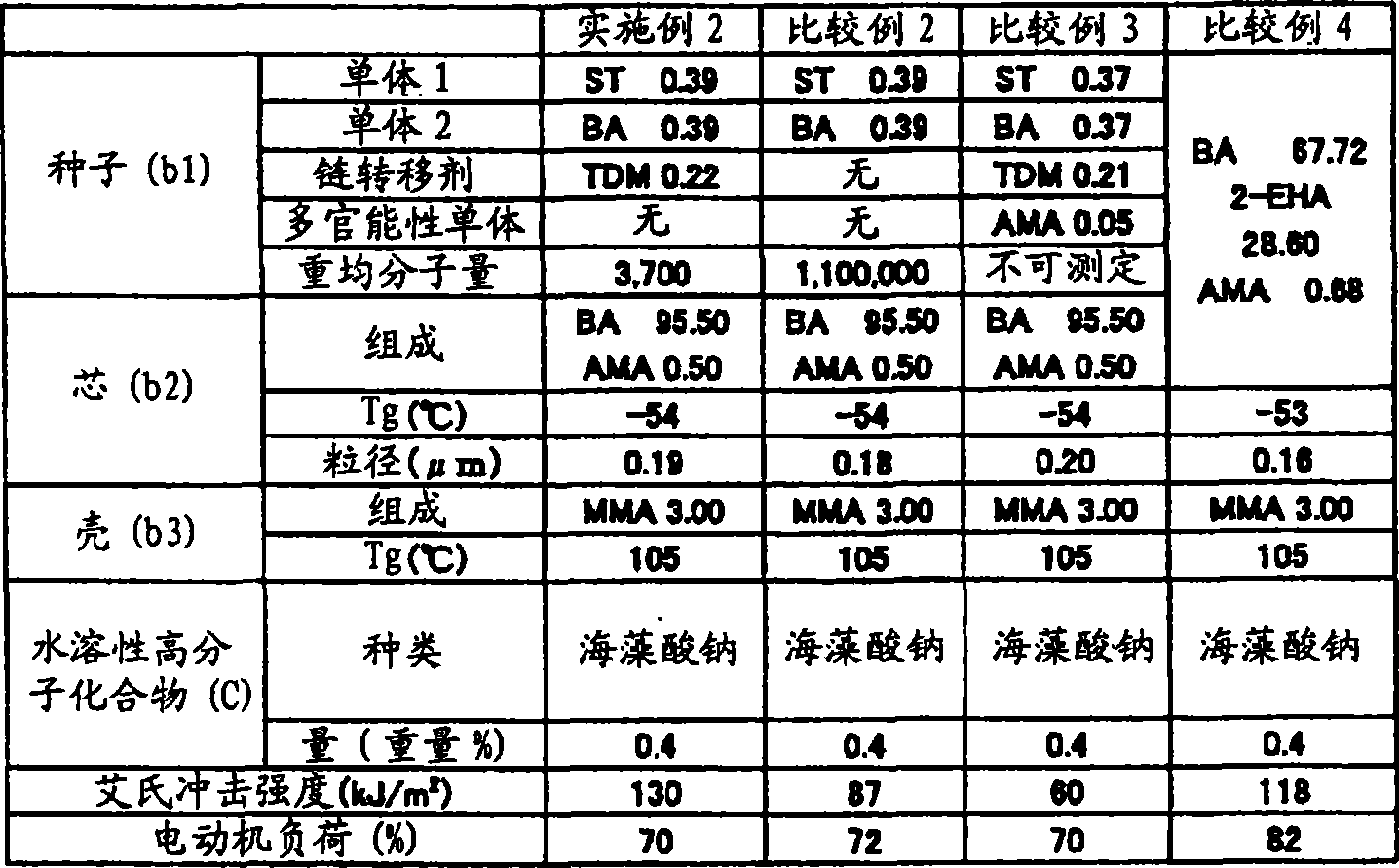

Embodiment 2

[0106] (Preparation of graft copolymer Y)

[0107]

[0108] In the glass reactor that has thermometer, stirrer, reflux cooler, nitrogen flow inlet, the adding device of monomer and the adding device of emulsifier, add 160 parts by weight of deionized water and 0.05 part by weight of sodium lauryl sulfate, then , and the temperature was raised to 55° C. while stirring in a nitrogen stream. Then, through the above-mentioned adding device, add 0.39 parts by weight of BA as the monomer mixture for the seed (b1), 0.39 parts by weight of ST, and a mixture of 0.22 parts by weight of TDM and 0.02 parts by weight of cumene hydroperoxide as a chain transfer agent, After 10 minutes, a mixed solution obtained by dissolving 0.001 parts by weight of disodium edetate and 0.0005 parts by weight of ferrous sulfate heptahydrate in 5 parts by weight of distilled water and 0.07 parts by weight of sodium formaldehyde sulfoxylate were added in this state. Stirring was carried out for 1 hour, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com