Production of iminodiacetic acid by microorganism catalytic processes and bacterial strain thereof

A technology of iminodiacetic acid and iminoacetonitrile, which is applied in the field of microbial catalytic production of iminodiacetic acid and its strains, achieving the effects of low equipment cost, less impurity content and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

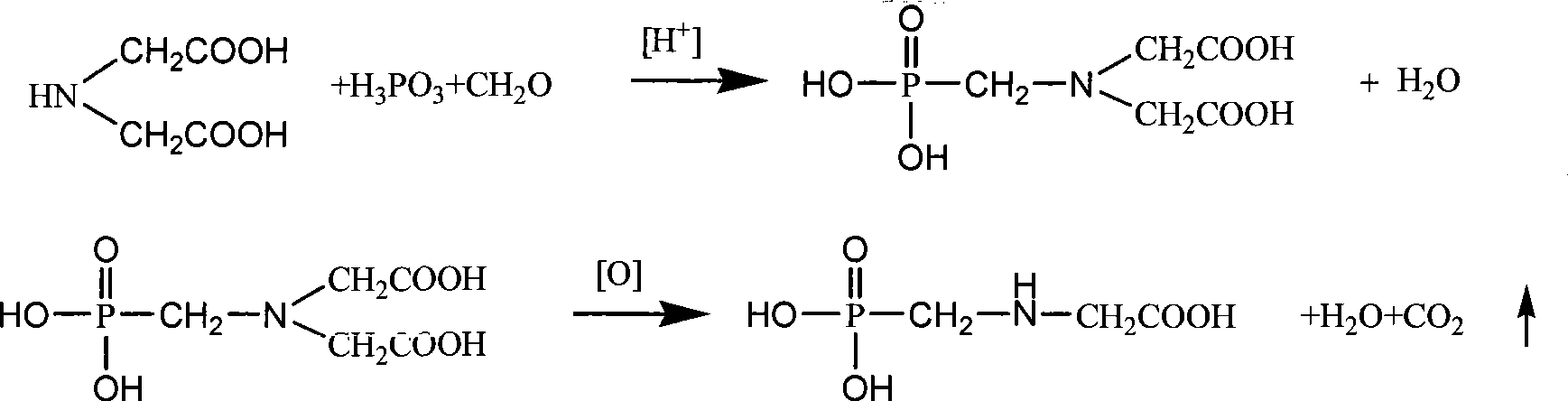

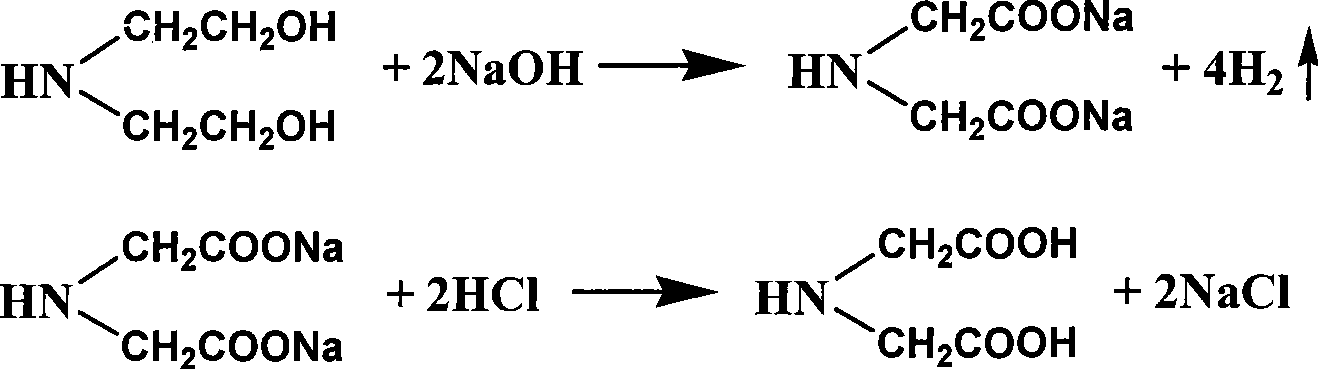

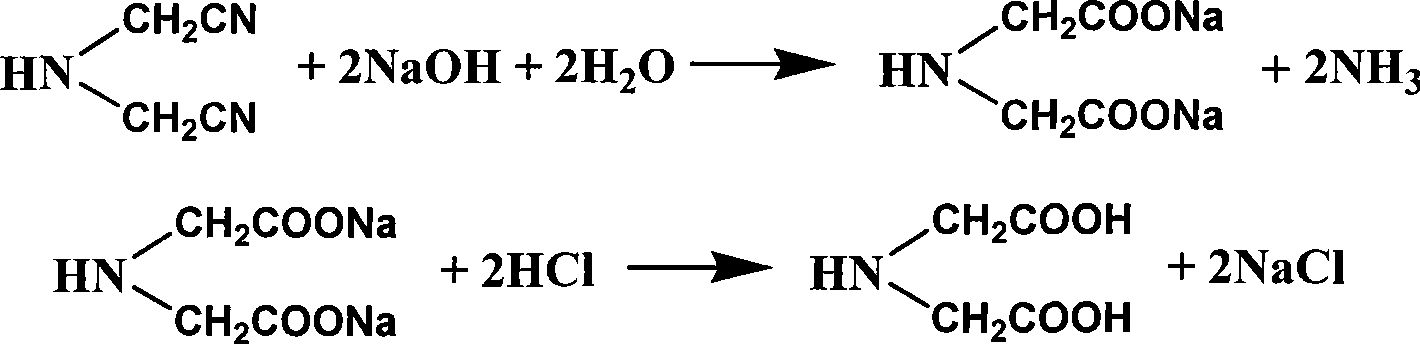

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Shake flask fermentation culture of Alcaligenes faecalis CCTCC No: M 208168.

[0059] Prepare shake flask fermentation medium A, B, C, D respectively, and its medium composition is as follows:

[0060] A: Ammonium acetate 0.5%, yeast extract 0.3%, K 2 HPO 4 0.3%, MgSO 4 0.01%, FeSO 4 0.001%, NaCl 0.05%, and adjust the pH to 7.0 with 2M hydrochloric acid or 2M sodium hydroxide.

[0061] B: Ammonium acetate 1%, yeast extract 0.5%, K 2 HPO 4 0.5%, MgSO 4 0.02%, FeSO 4 0.003%, NaCl 0.1%, and adjust the pH to 7.5 with 2M hydrochloric acid or 2M sodium hydroxide.

[0062] C: Ammonium acetate 2.0%, yeast extract 0.5%, K 2 HPO 4 0.8%, MgSO 4 0.05%, FeSO 4 0.003%, NaCl 0.03%, adjust the pH to 8.0 with 2M hydrochloric acid or 2M sodium hydroxide.

[0063] D: Ammonium acetate 2.0%, yeast extract 0.8%, K 2 HPO 4 0.8%, MgSO 4 0.1%, FeSO 4 0.01%, NaCl 0.5%, and adjust the pH to 8.5 with 2M hydrochloric acid or 2M sodium hydroxide.

[0064] Pour the ...

Embodiment 2

[0067] Embodiment 2: Fermentation tank fermentation culture of Alcaligenes faecalis (Alcaligenes faecalis) CCTCC No: M 208168

[0068] Preparation of seed medium: ammonium acetate 1%, yeast extract 0.5%, K 2 HPO 4 0.5%, MgSO 4 0.02%, FeSO 4 0.003%, NaCl 0.1%, and adjust the pH to 7.5 with 2M hydrochloric acid or 2M sodium hydroxide.

[0069] Prepare fermenter fermentation medium a, b, c, d respectively, and its fermentation medium composition is as follows:

[0070] a: Ammonium acetate 0.5%, yeast extract 0.3%, K 2 HPO 4 0.3%, MgSO 4 0.01%, FeSO 4 0.001%, NaCl 0.05%, and adjust the pH to 7.0 with 2M hydrochloric acid or 2M sodium hydroxide.

[0071] b: Ammonium acetate 1%, yeast extract 0.5%, K 2 HPO 4 0.5%, MgSO 4 0.02%, FeSO 4 0.003%, NaCl 0.1%, and adjust the pH to 7.5 with 2M hydrochloric acid or 2M sodium hydroxide.

[0072] c: Ammonium acetate 2.0%, yeast extract 0.5%, K 2 HPO 4 0.8%, MgSO 4 0.05%, FeSO 4 0.003%, NaCl 0.03%, adjust the pH to 8.0 ...

Embodiment 3

[0078] Embodiment 3: fermented liquid centrifugation or membrane filtration

[0079] Get 2L of the fermented liquid obtained by the fermentation of medium b in Example 2, centrifuge with a low-temperature high-speed centrifuge (at 4°C, centrifuge at 12000rpm for 15min), filter with a hollow fiber membrane (flow rate 150mL / min, pressure 0.8Kg / cm 2 ), roll membrane filtration (flow 150mL / min, pressure 16Kg / cm 2 ), ceramic membrane filtration (flow 150mL / min, pressure 4Kg / cm 2 ) or flat ultrafiltration membrane (Ultra-fla) filtration (flow rate 150mL / min, pressure 3Kg / cm 2 ) method to process the fermentation broth. The cells were then washed with 4L of deionized water, and the wet cells were collected to measure the enzyme activity (the assay method was the same as in Example 1). The results are shown in Table 3.

[0080] Table 3: Wet cell enzyme activity after fermentation broth treatment

[0081] Processing method of fermentation broth Enzyme activity of wet ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com