Planar MOSFET integrated with schottky diode and its layout method

一种栅极、顶表面的技术,应用在二极管、半导体器件、电气元件等方向,能够解决易发生击穿曲率半径、高成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

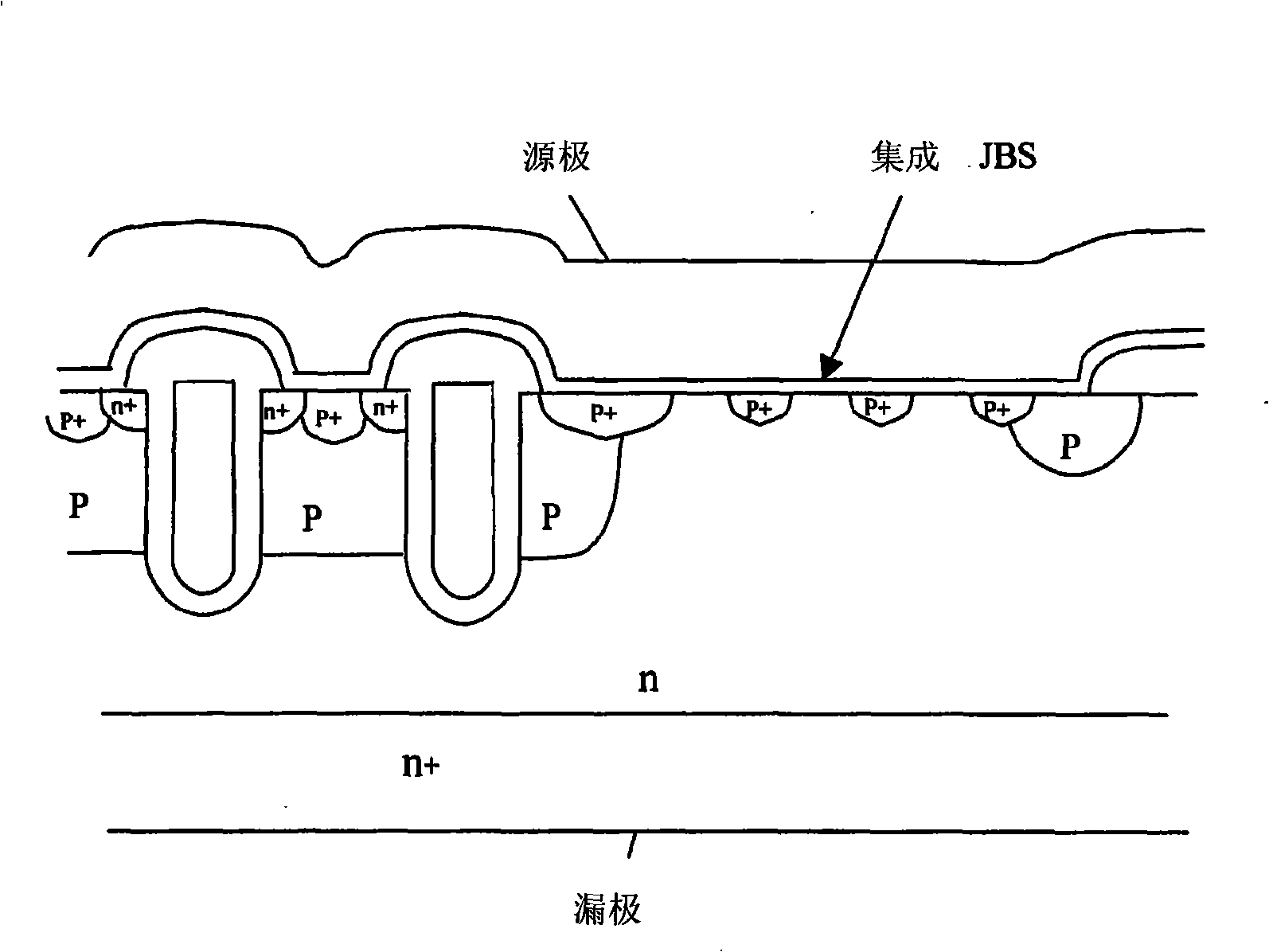

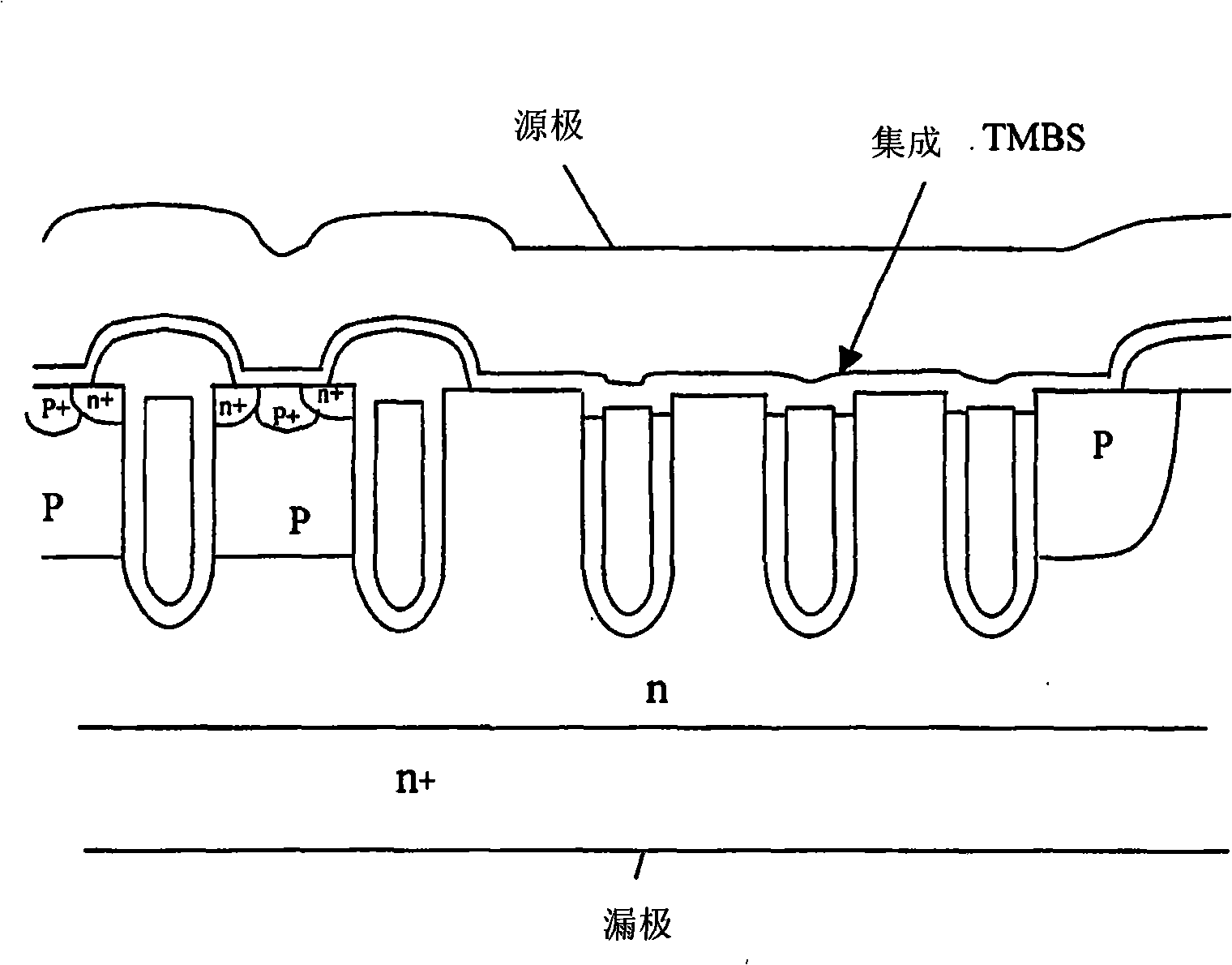

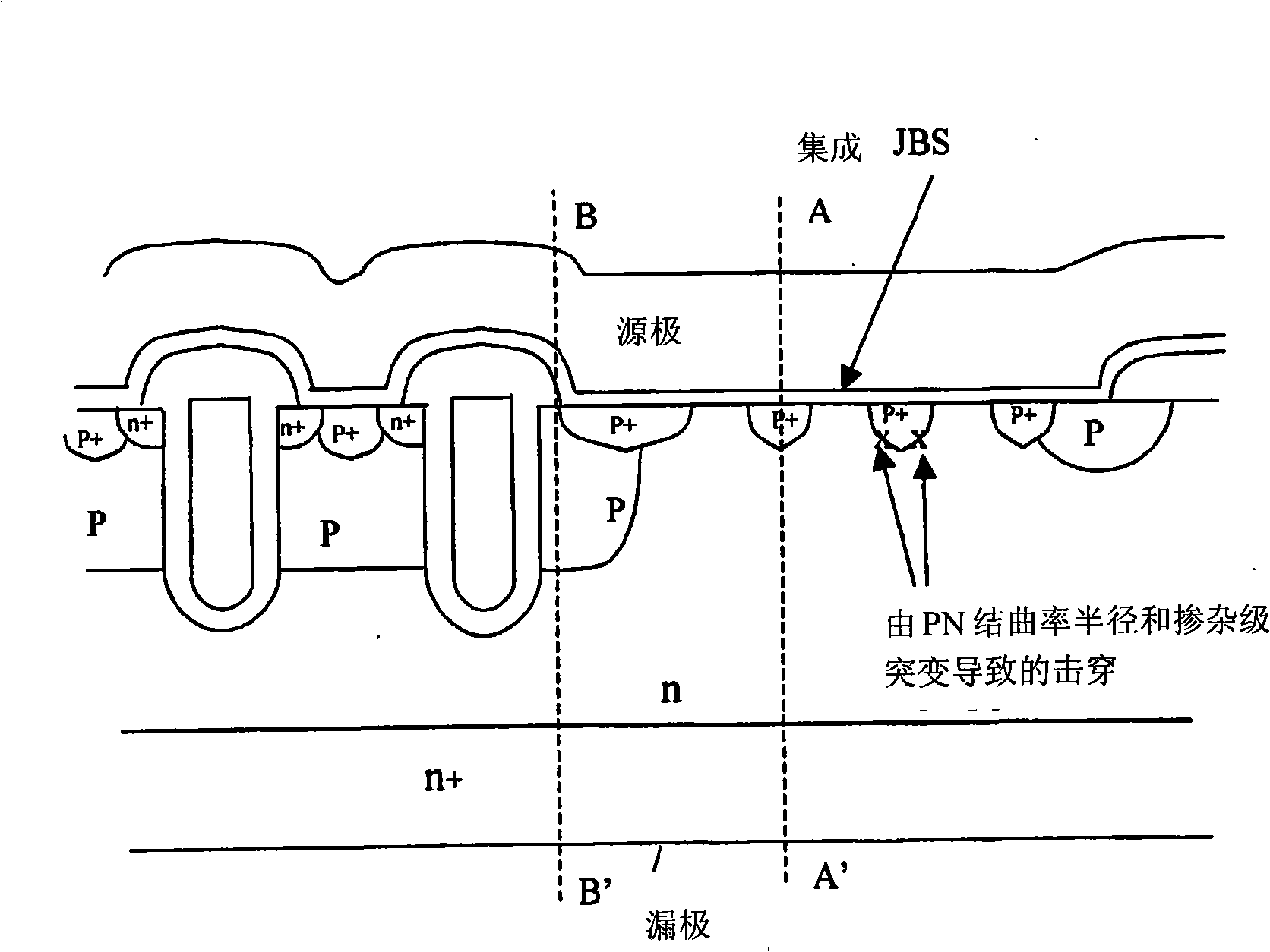

[0038] Such as Figure 3A and Figure 3B Shown is a schematic side cross-sectional view of the JBS region that provides the MOSFET device modification function, Figure 3A Blank implantation of body-type shallow dopant ions is shown. For N-channel MOSFET devices, the doping concentration is 5×10 11 / cm 2 ~5×10 12 / cm 2 The boron ions are implanted into the epitaxial layer, and the implantation energy is 40-500Kev, preferably 80-300Kev. The blank implantation of body-type ions compensates and reduces the doping concentration of a part of the epitaxial layer, thereby increasing the breakdown voltage of the epitaxial layer. exist Figure 3B , using higher diffusion temperatures (ranging from 1000°C to 1150°C for 1 to 3 hours) to diffuse the body-type dopant to a shallower depth than the MOSFET body region formed in subsequent steps, the implanted The doping ions of the body region type compensate the doping of the epitaxial layer, and generate N-regions in the epitaxial l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com