Method for constructing ester bond enzyme engineering bacteria for tendency hydrolysis of TAG sn-2 and corresponding recombinant lipase

A technology of engineering bacteria and ester bond enzymes, applied in the directions of hydrolase, genetic engineering, recombinant DNA technology, etc., can solve the problems of limited industrial application and low yield, and achieve the effects of low production cost and simple induction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, a method for constructing engineering bacteria with a tendency to hydrolyze the TAG sn-2 position ester bond enzyme, the following steps are carried out in sequence:

[0050] 1), the cloning of CAL-A gene

[0051] EcoR I and Not I on pPPIC9K were selected as restriction enzyme sites, and a pair of specific primers were designed.

[0052] Upstream primer (LPU): AATAAGGAATTCGCGGCGCTGCCCAACCCCTACGAC

[0053] Downstream primer (LPD): AAGGAAAAAAGCGGCCGCCATCGACCGTGGGAACTG

[0054] The Candida antarctica genome was used as a template for PCR amplification. The PCR system is as follows: Buffer (no Mg 2+ )5μL, Mg 2+ Solution 5 μL, dNTP solution 4 μL, upstream primer 1 μL, downstream primer 1 μL, template 1 μL, Taq enzyme 0.5 μL, add water to make up 50 μL. The amplification conditions were as follows: 95°C for 5 minutes; 30 cycles of 94°C for 1 minute, 65°C for 1 minute, and 72°C for 1 minute; and 72°C for 10 minutes. After amplification, the kit (TaKaRa DNA ...

Embodiment 2

[0066] Embodiment 2, a kind of method utilizing the engineering bacterium obtained in embodiment 1 to prepare recombinant lipase adopts the induced expression of yeast, and concrete steps are as follows:

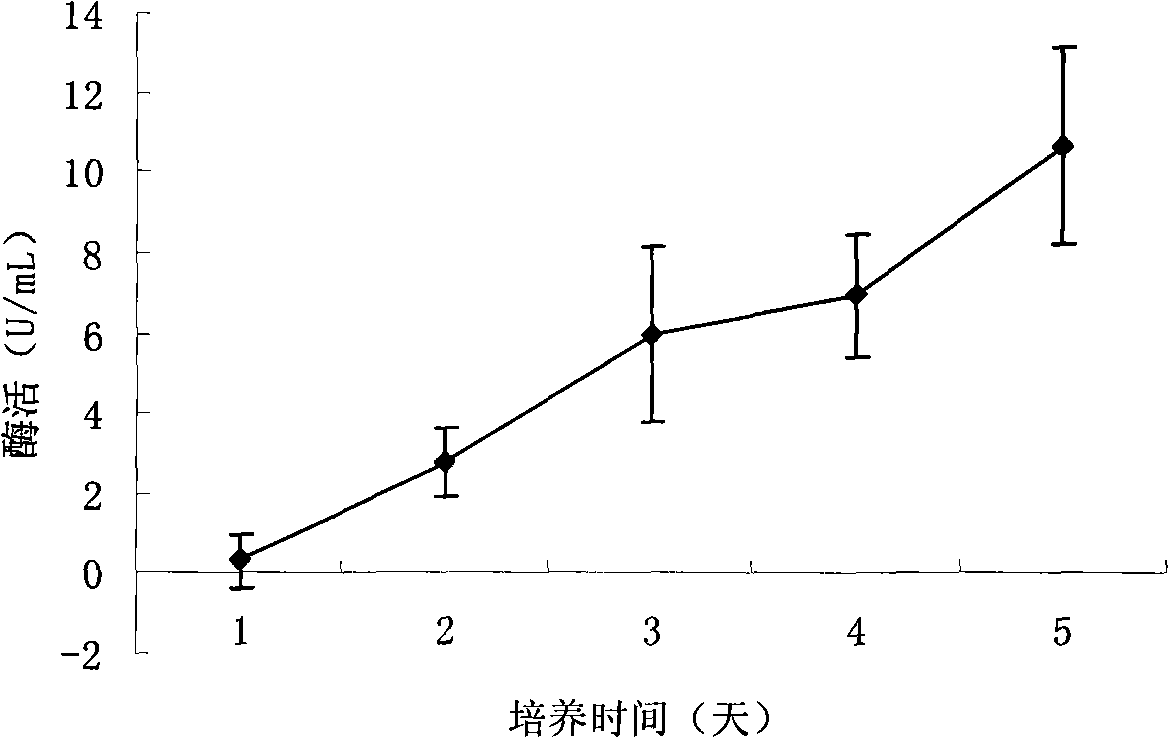

[0067] The positive transformants obtained in Example 1 were inoculated into BMGY medium, and cultured overnight at 30°C until OD 600 2 to 6, and then centrifuged to collect the bacteria. Dilute the obtained bacteria with BMMY medium to OD 600 1, adding 0.5% of the total volume of methanol every 12h to induce expression. Take 1.5ml of the culture solution for centrifugation every 24 hours, and the supernatant is the crude enzyme solution of the recombinant lipase. Induction continued until cessation on day 5.

Embodiment 3

[0068] Embodiment 3, adopt sodium hydroxide titration method to measure lipase activity

[0069] Preparation of polyvinyl alcohol olive oil emulsion: Add 4 g of polyvinyl alcohol into 100 mL of ultrapure water, heat and dissolve in microwave to form a polyvinyl alcohol solution. Then mix the polyvinyl alcohol solution and olive oil at a ratio of 4:1 (w:w), and stir 3 times with a high-speed tissue homogenizer, each time for 1 minute, with an interval of 3 minutes; to obtain a polyvinyl alcohol olive oil emulsion.

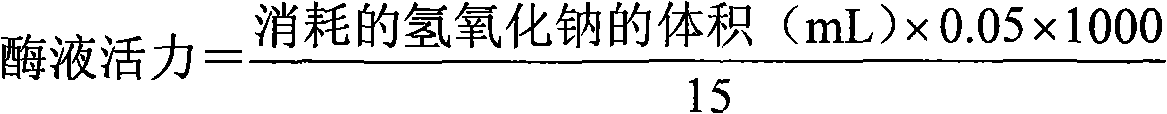

[0070] The lipase activity assay procedure is as follows: add 0.025mol / L, pH 7.5 phosphate buffer 5mL and polyvinyl alcohol olive oil emulsion 4mL in Erlenmeyer flask, bathe in water at 40°C for 5min. Then add 1 mL of the crude enzyme solution obtained in Example 2, react for 15 min, add 15 mL of 95% ethanol to terminate the reaction, and then add 3 drops of phenolphthalein indicator. Titrate with 0.05mol / L sodium hydroxide until the solution turns pink, and subtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com