Energy-saving production method for layered crystal sodium disilicate

A sodium disilicate, layered crystallization technology, applied in the direction of silicate, alkali metal silicate, energy input, etc., can solve the problem that the product cannot be mixed with washing powder, the crystallization furnace has no heat storage device, and the thermal insulation sealing layer is not suitable. It can achieve the effect of adapting to cleaner production, reducing kiln exhaust gas emissions and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

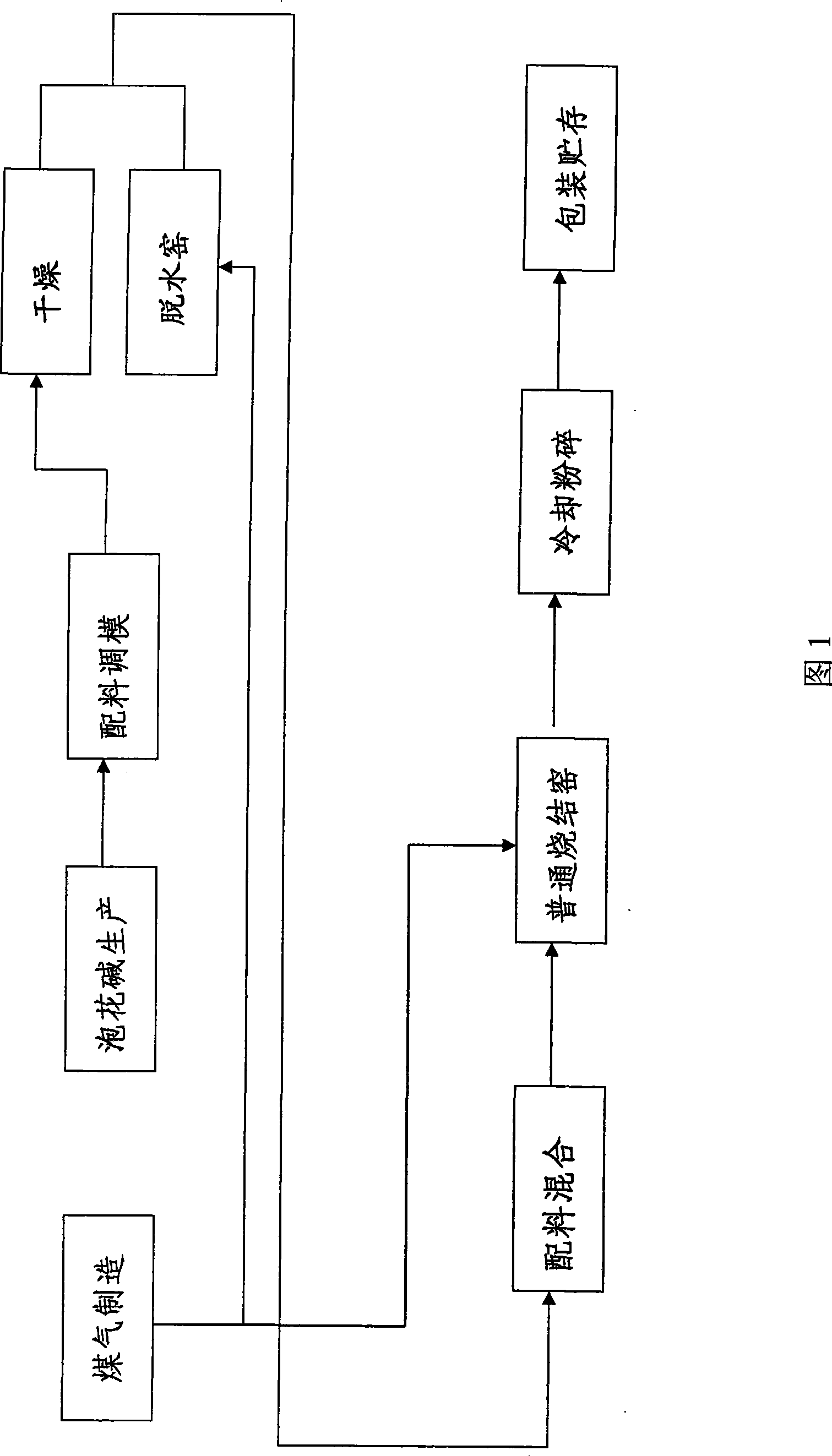

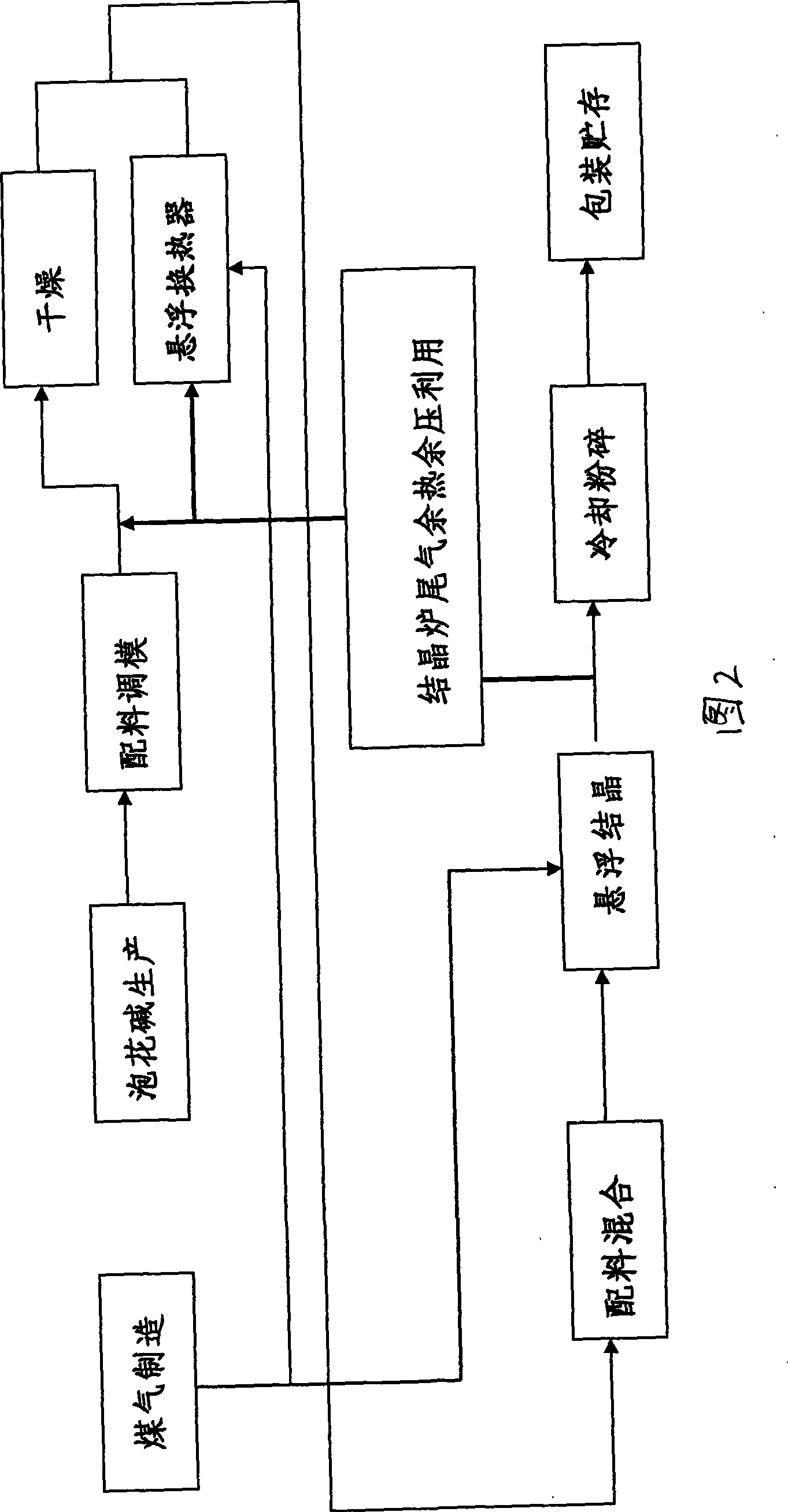

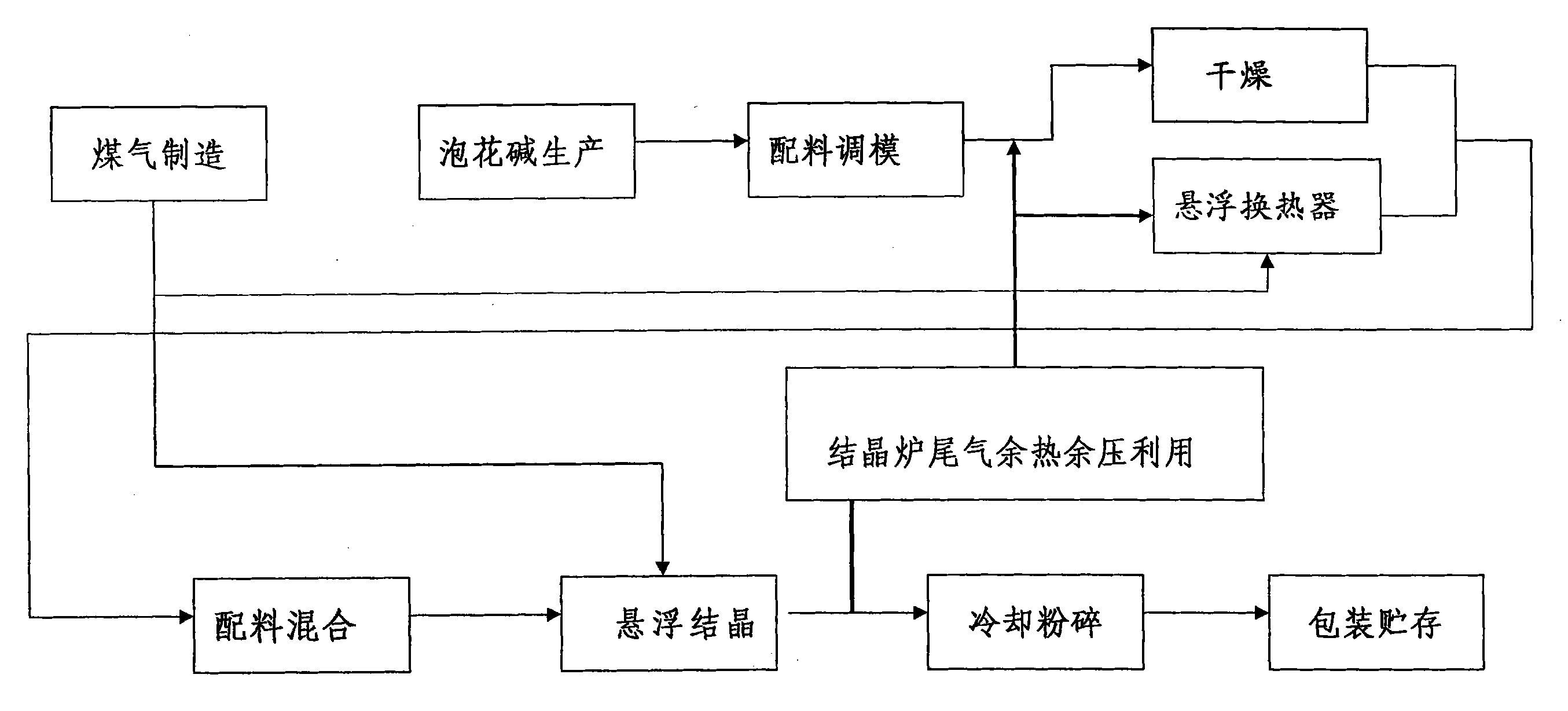

Image

Examples

Embodiment

[0026] Embodiment: The gas produced by the gas station is transported to the crystallization furnace (ф1800*16000) and the drying tower and suspension heat exchanger through pipelines. The temperature of the crystallization furnace is 850-900 ° C, and the thermal efficiency is 69%. 330°C, air outlet temperature 110°C, effective heat energy 4.1×10 6 KJ; the maximum intake air temperature of the suspension heat exchanger is 900°C; the tail gas temperature of the crystallization furnace is 500-600°C, and the effective heat energy is 9.85×10 6 KJ. The high-temperature gas discharged from the tail of the crystallization furnace is used for drying the liquid sodium hydroxide through the pipeline, which can save 1 / 3 of fuel consumption in production. While the waste heat is utilized, the 2‰ uncrystallized powder contained in the crystallization tail gas is recovered and reused to realize clean production and achieve the purpose of saving energy and reducing consumption.

[0027]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com