Aluminosilicate blue fluorescent powder and preparation thereof

A technology of blue fluorescent powder and aluminosilicate, applied in the direction of silicate, aluminum silicate, chemical instruments and methods, etc., can solve the problems of unfavorable environmental protection, poor luminous performance, high synthesis temperature, etc., and achieve good luminous characteristics and stability, easy industrial production, and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

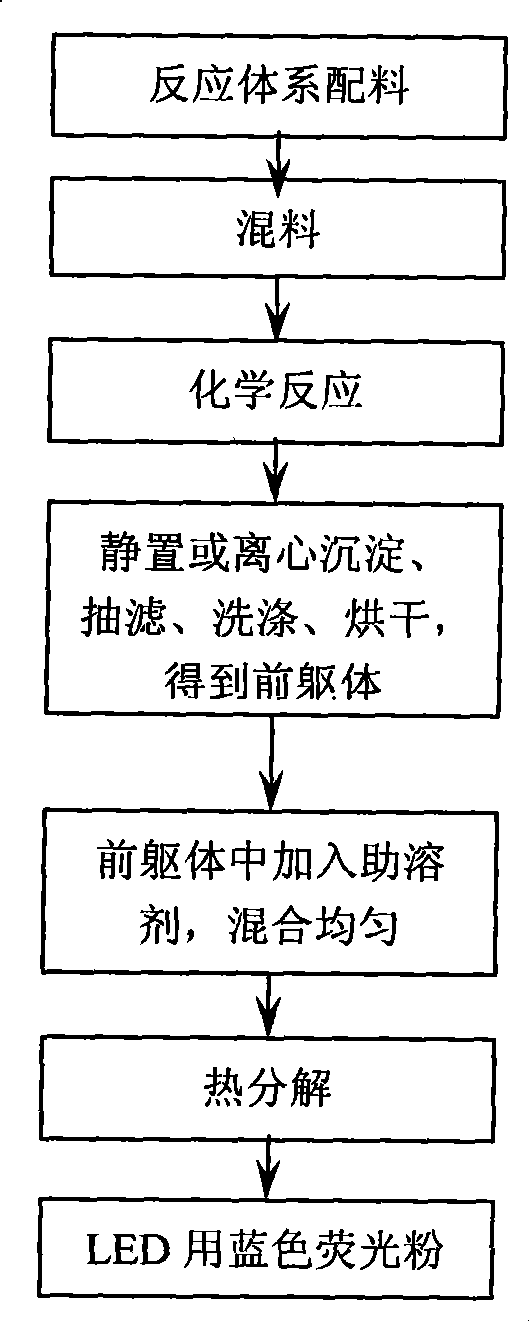

Method used

Image

Examples

Embodiment 1

[0029] According to chemical formula Ba 0.985 al 2 Si 2 o 8 :0.015Eu 2+ Weigh the Ba(NO 3 ) 2 (A.R.)0.985mol, Al(NO 3 ) 3 9H 2 O(A.R.)2mol, H 2 SiO 3 (A.R.)2mol, Eu 2 o 3 (99.99%) 0.0075mol; Then take respectively the surfactant polyethylene glycol and the fluxing agent H of the total mass of the above medicines 0.2wt%. 3 BO 3 ; Preparation of precipitant NH 4 HCO 3 solution, the concentration is 1mol / L; the weighed Eu 2 o 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water and heat to 25°C for water bath treatment; add Ba(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O, H 2 SiO 3 , polyethylene glycol, stirring at the same time, and adding the precipitant solution several times, adjusting PH=7, and continuing to stir for 4 hours; standing, suction filtering, washing, and drying to obtain a fluffy precursor; After taking the good flux and mixing it evenly, place it in a muffle furnace protected by a reducing atmosphere for c...

Embodiment 2

[0031] According to chemical formula Ba 0.975 al 2 Si 2 o 8 :0.025Eu 2+ Weigh out BaCO 3 (A.R.)0.975mol, Al(NO 3 ) 3 9H 2 O(A.R.)2mol, H 2 SiO 3 (A.R.)2mol, Eu 2 o 3(99.99%) 0.0125mol; Then take respectively the surfactant polyethylene glycol and the fluxing agent MgF of the above drug gross mass 0.4wt% 2 ; Preparation of precipitant (NH 4 ) 2 CO 3 solution with a concentration of 2mol / L; the weighed Eu 2 o 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water and heat to 45°C for water bath treatment; add BaCO to the above solution 3 , Al(NO 3 ) 3 9H 2 O, H 2 SiO 3 , polyethylene glycol, stirring at the same time, and adding the precipitant solution several times, adjusting PH=8, and continuing to stir for 3 hours; standing, suction filtering, washing, and drying to obtain a fluffy precursor; After taking the good flux and mixing it evenly, place it in a muffle furnace protected by a reducing atmosphere for ca...

Embodiment 3

[0033] According to chemical formula Ba 0.965 al 2 Si 2 o 8 :0.035Eu 2+ Weigh the Ba(NO 3 ) 2 (A.R.)0.965mol, Al(NO 3 ) 3 9H 2 O(A.R.)2mol, H 2 SiO 3 (A.R.)2mol, Eu 2 o 3 (99.99%) 0.0175mol; Then take respectively surfactant polyethylene glycol and fluxing agent Li 2 CO 3 ; Preparation of precipitant C 2 h 2 o 4 solution with a concentration of 3mol / L; the weighed Eu 2 o 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water and heat to 65°C for water bath treatment; add Ba(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O, H 2 SiO 3 , polyethylene glycol, stirring at the same time, and adding the precipitant solution several times, adjusting PH=9, and continuing to stir for 2 hours; standing, filtering, washing, and drying to obtain a fluffy precursor; After taking the good flux and mixing it evenly, place it in a muffle furnace protected by a reducing atmosphere for calcination, the calcination temperature is 1100°C, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com