Method for producing butanol

A technology for producing butanol and butanol, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficult to exceed the yield of butanol fermentation, high toxicity of production strains, poor chemical stability, etc., to achieve The effect of improving in-situ separation efficiency, reducing the steps of extracting butanol, and simplifying production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

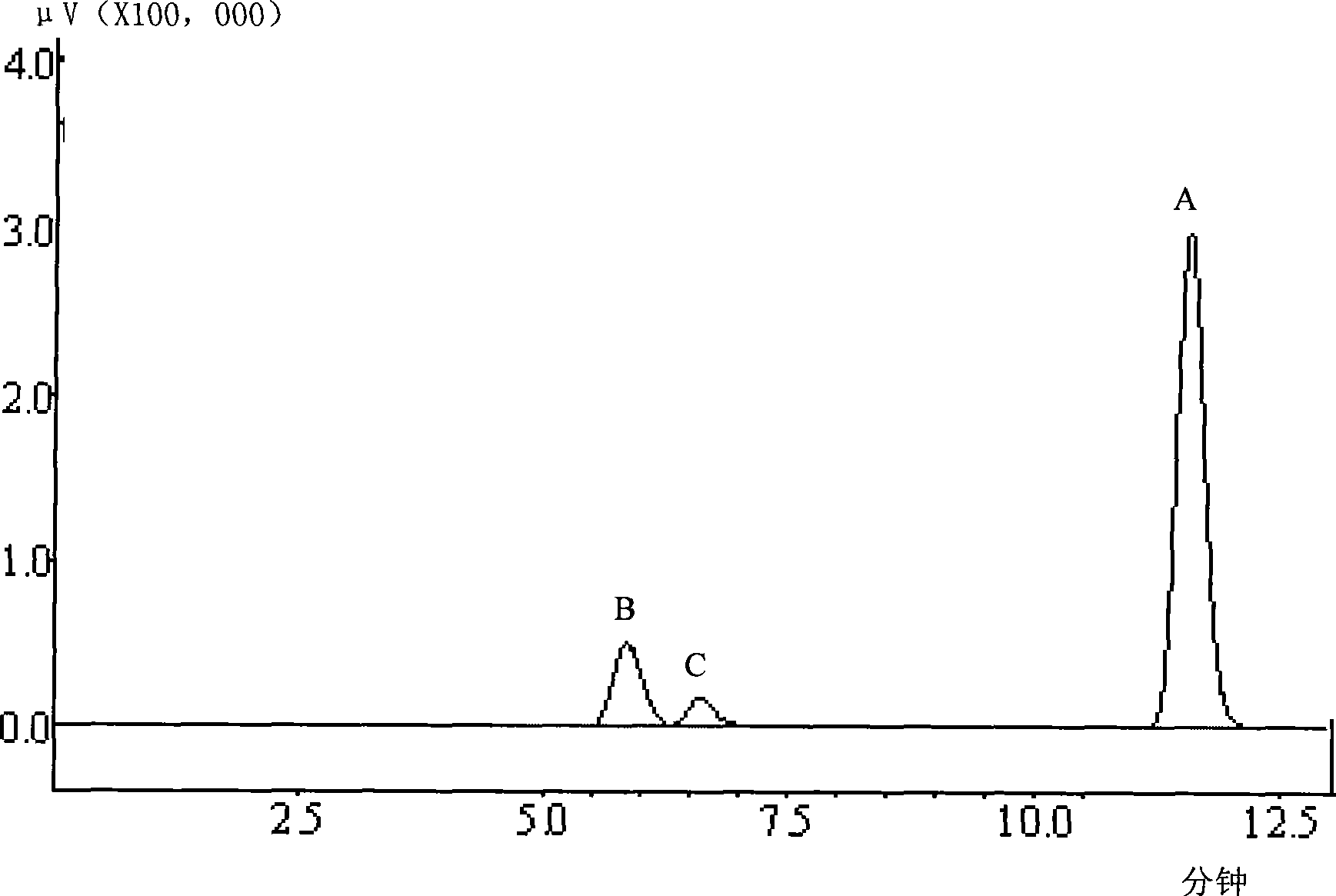

[0038] Embodiment 1, with CGM culture medium liquid-liquid extraction-continuous air stripping fermentation

[0039] Inoculate C.acetobutylicum SMB-1 CGMCC №.2287 into RCM medium, and culture it statically in a 37°C incubator until the logarithmic phase, as a fermentation seed solution.

[0040] The fermented seed liquid obtained above was inoculated into a 7L fermenter equipped with 3L of CGM medium according to the volume percentage of 5% for fermentation. Control the pH value in the fermenter to 5.0 (the pH is not controlled at the beginning of the fermentation, when the pH of the fermentation liquid drops to 5.0, the pH is automatically controlled at 5.0 by adding 4mol / L NaOH automatically), the fermentation temperature is 37°C, and the fermentation method is static fermentation. Counting from the beginning of fermentation, after 24 hours of fermentation, add 0.6 L of organic solvent (volume of organic solvent to fermentation medium) mixed with oleyl alcohol and decanol (...

Embodiment 2

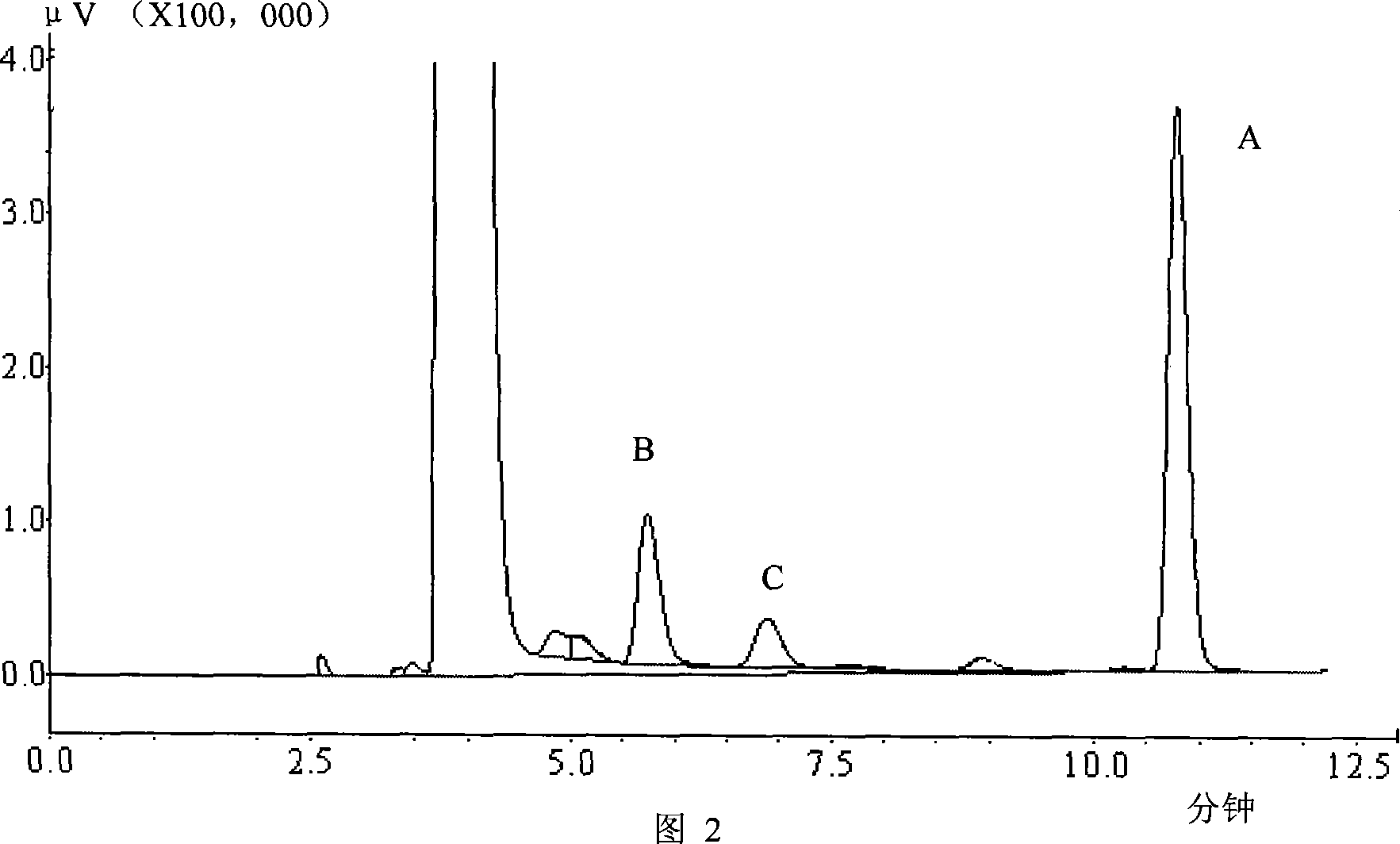

[0046] Embodiment 2, with CGM culture medium liquid-liquid extraction-intermittent air stripping fermentation

[0047] The cultivation of the fermented seed liquid was the same as described in Example 1.

[0048] The fermented seed liquid obtained above was inoculated into a 7L fermenter equipped with 3L of CGM medium according to the volume percentage of 5% for fermentation. Control the pH value in the fermenter to 4.5 (the pH is not controlled at the beginning of the fermentation, when the pH of the fermentation broth drops to 4.5, the pH is automatically controlled at 4.5 by adding 4mol / L NaOH automatically), the fermentation temperature is 35°C, and the fermentation method is static fermentation. Counting from the beginning of fermentation, after 12 hours of fermentation, add 0.3 L of organic solvent (the amount of fermentation medium to organic solvent) mixed with oleyl alcohol and decanol (the volume ratio of oleyl alcohol and decanol is 1:1) to the reaction system. Th...

Embodiment 3

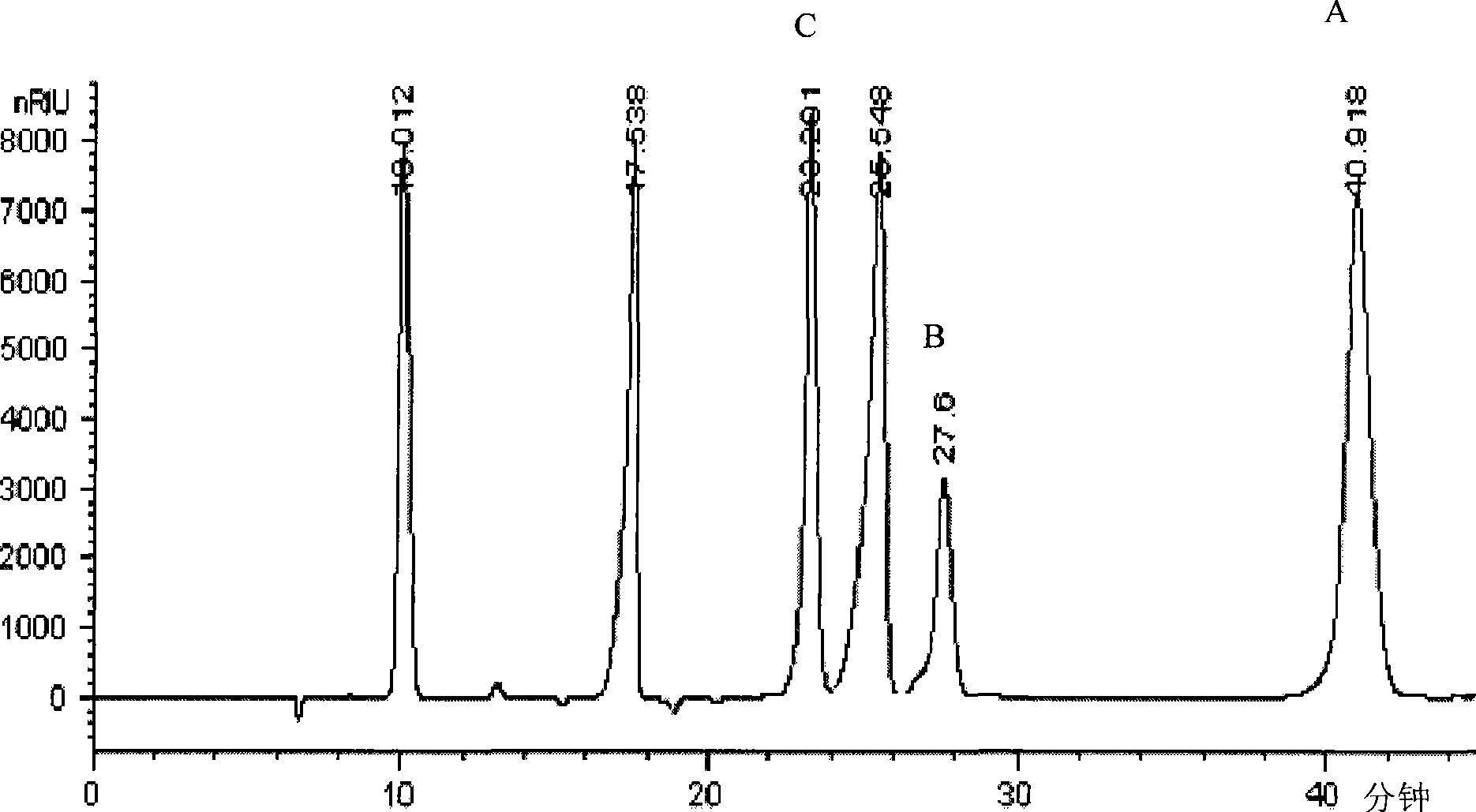

[0051] Embodiment 3, with cornstarch culture medium liquid-liquid extraction-intermittent air stripping fermentation

[0052] The cultivation of the fermented seed liquid was the same as described in Example 1.

[0053] The fermented seed liquid obtained above was inoculated into a 7L fermenter equipped with 3L cornstarch medium according to the volume percentage of 5% for fermentation. The fermentation temperature is 39°C, and the fermentation method is static fermentation. From the beginning of fermentation, after 30 hours of fermentation, 1.5 L of organic solvent (the volume ratio of oleyl alcohol and decanol is 10:1) mixed with oleyl alcohol and decanol (the volume ratio of oleyl alcohol and decanol) was added to the reaction system. The volume ratio is 2:1). At the same time, hydrogen is introduced through the ventilation pipe at the bottom of the fermenter. The ventilation time is 1h, and the hydrogen flow rate is 1.5L gas / min. The gas flow rate is the same as above; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com