Method for preparing active carbon for polar electric pole by using biomass material as raw material

A biomass material, biomass raw material technology, applied in the field of activated carbon manufacturing, can solve the problems of unable to form industrial scale production, unable to stably control the activation process, unable to obtain activation products and other problems, to achieve strong electrical conductivity, inside pores and other problems. Clean, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]② Electrode preparation: According to the ratio of activated carbon (after pulverization and surface treatment): PTFE: conductive additive (carbon black) = 8:1:1, mix with solvent, mix evenly in a mixer, dry, and press tablet Machine or roller compactor to press into 100-150um thin slices, punch out circular electrode sheets with a certain area by punching machine, and do vacuum drying.

[0043] ③Electrolyte: use 1M Et 4 NBF 4 / PC solution.

[0044] ④ Diaphragm: Use cellulose non-woven fabric with a thickness of 40 μm and dry it in vacuum.

[0045] ⑤ Assembly of EDLC cell: In a glove box, an EDLC cell was assembled using a dried stainless steel cell device for lithium ion secondary battery measurement. The specific operation is: open the stainless steel unit, put in a piece of activated carbon electrode, place a diaphragm on it, insert a Teflon ferrule for fixing, add 0.5ml of 1MEt 4 NBF 4 / PC solution, then put 1 piece of activated carbon electrode, place a metal g...

Embodiment 1

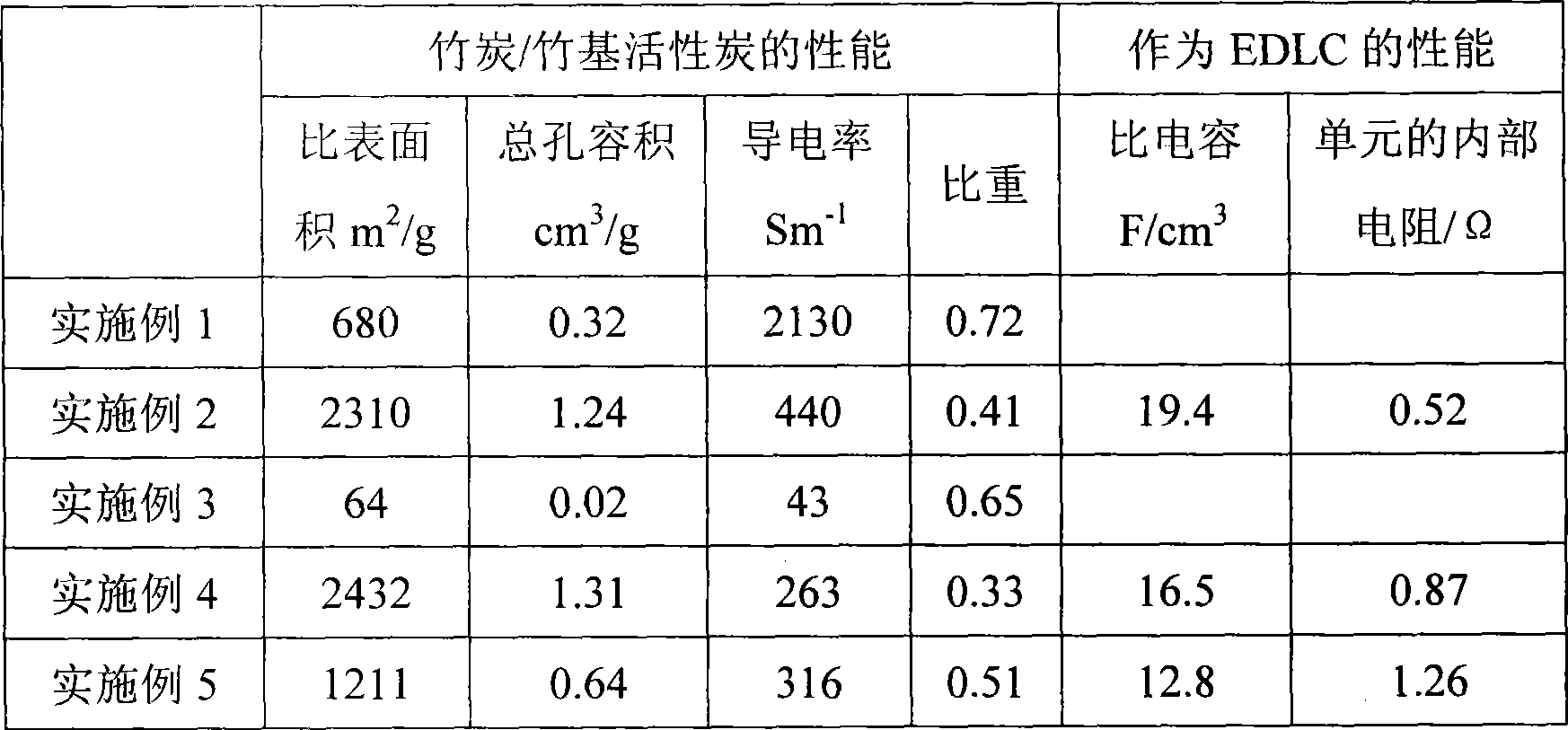

[0048] Bamboo chips are used as an example for biomass raw materials. Bamboo chips of 2-10 cm are used to obtain bamboo charcoal after carbonization at 1000 ° C for 2 hours in a retort furnace, and then crushed to an average particle size of 200-300 μm, which becomes the raw material of bamboo-based activated carbon for supercapacitor electrodes. Properties such as specific surface area, total pore volume, micropore volume, specific gravity, and electrical conductivity are summarized in Table 1. It can be seen that the bamboo charcoal has a high specific surface area and good electrical conductivity.

Embodiment 2

[0050] Use the bamboo charcoal of Example 1, mix KOH according to the carbon-to-alkali weight ratio of 1:3, raise the temperature to 550°C while stirring, and keep the temperature at 500-600°C for 2 hours, then raise the temperature to 800°C, and keep the temperature between 700-900°C for 0.5 hours. After cooling, wash with deionized water / acid several times, dry, and grind to an average particle size of 10-15 mm to obtain powdered activated carbon. Properties such as specific surface area, total pore volume, specific gravity, and electrical conductivity are summarized in Table 1. It can be seen that the obtained activated carbon has a large specific surface area, well-developed pores, high conductivity and high specific gravity. The charge and discharge test was carried out as the electrode material of supercapacitor, and the results are shown in Table 1. Bamboo-based activated carbon activated by this method, as an electrode material for EDLC, has high specific capacitance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com