Boron doped titanic oxide nano tube thin-film photoelectric electrode and preparing method thereof

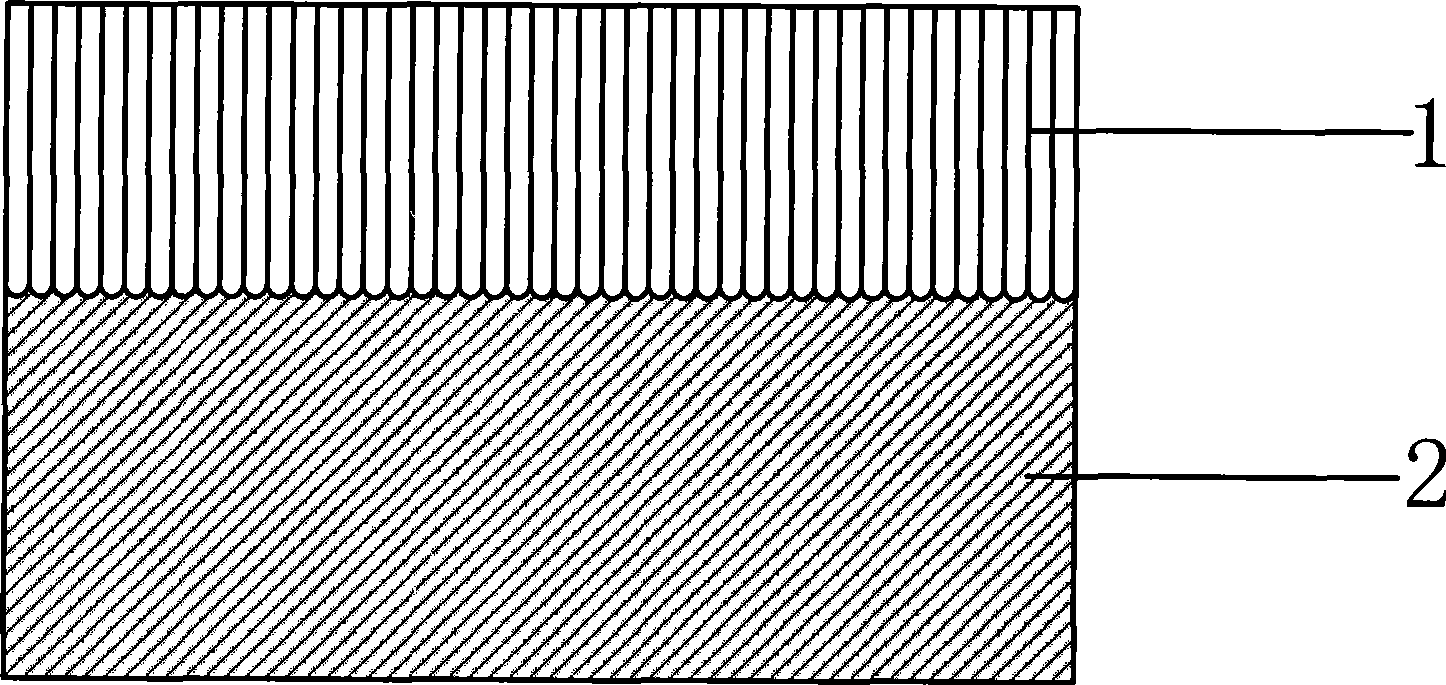

A technology of titanium dioxide and nanotubes, which is applied in the field of boron-doped titanium dioxide nanotube thin film photoelectrodes and its preparation, can solve the problems of low photoelectric conversion efficiency, immobilization, and inability to use visible light, and achieve the improvement of photoelectric conversion efficiency. The effect of easy control of impurity concentration and high active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take NH 4 F2.5 grams, 5 grams of oxalic acid are dissolved in 500 milliliters of water, and the pH value is adjusted to 3.7 to obtain an electrolyte; the treated titanium sheet is used as an anode, and the cathode is a nickel plate, and anodic oxidation is carried out for 120 minutes at a voltage of 20V. Obtain an amorphous titanium dioxide nanotube structure; then use chemical vapor deposition to do boron doping, where the precursor solution is 50g / L H at 50°C 3 BO 3 solution; nitrogen as carrier gas, flow rate 0.015m / s; deposition at 700°C for 2 hours; after the deposition, continue to flow nitrogen to remove the residual precursor in the deposition chamber, and then calcined at 700°C for 1 hour under the protection of nitrogen, and cooled naturally .

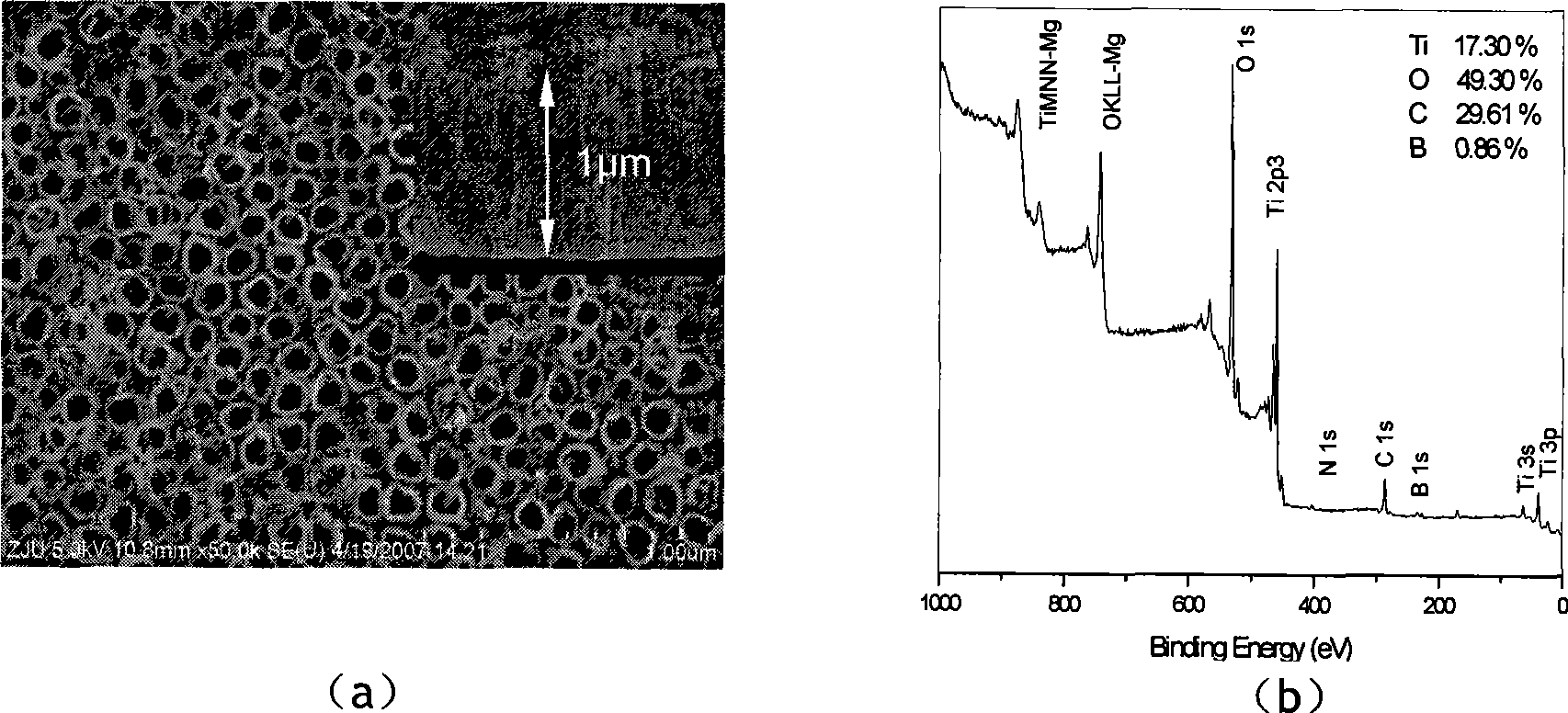

[0023] figure 2 (a) is a scanning electron micrograph of the surface and cross section of the nanotube film, the tube length of the nanotube is about 1 micron, and the tube diameter is about 50 nanometers. figure...

Embodiment 2

[0025] Take NH 4 F2.5 grams, 5 grams of oxalic acid are dissolved in 500 milliliters of water, and the pH value is adjusted to 4.9 to obtain an electrolyte; the treated titanium sheet is used as an anode, and the cathode is a nickel plate, and anodic oxidation is carried out for 30 minutes at a voltage of 15V. Obtain an amorphous titanium dioxide nanotube structure; then use chemical vapor deposition to do boron doping, where the precursor solution is 50g / L H at 50°C 3 BO 3 solution; nitrogen as carrier gas, flow rate 0.002m / s; deposit at 700°C for 100 minutes, continue to flow nitrogen after the deposition to remove residual precursors in the deposition chamber, then calcinate at 700°C for 2 hours under nitrogen protection, and cool naturally .

[0026] The nanotube has a length of 323 nanometers, a pipe diameter of 35 nanometers, and a boron doping concentration of 0.46 at.%.

Embodiment 3

[0028] Take NH 4 F2.5 grams, 5 grams of oxalic acid are dissolved in 500 milliliters of water, and the pH value is adjusted to 2.7 to obtain an electrolyte; the treated titanium sheet is used as an anode, and the cathode is a nickel plate, and anodic oxidation is carried out for 100 minutes at a voltage of 25V. Obtain an amorphous titanium dioxide nanotube structure; then use chemical vapor deposition to do boron doping, where the precursor solution is 50g / L H at 50°C 3 BO 3 Solution, nitrogen as the carrier gas, flow rate 0.02m / s; deposition at 700°C for 150 minutes; after the deposition, continue to flow nitrogen to remove the residual precursor in the deposition chamber, and then calcined at 700°C for 3 hours under the protection of nitrogen, and cooled naturally .

[0029] The nanotube has a length of 867 nanometers, a pipe diameter of 75 nanometers, and a boron doping concentration of 1.42 at.%.

[0030] The photoelectrode in the embodiment of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com