Compound feed for shrimp and method for preparing the same

A technology for compounding feed and feed additives, which is applied in the field of feed to achieve the effects of promoting shrimp feeding, improving palatability and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

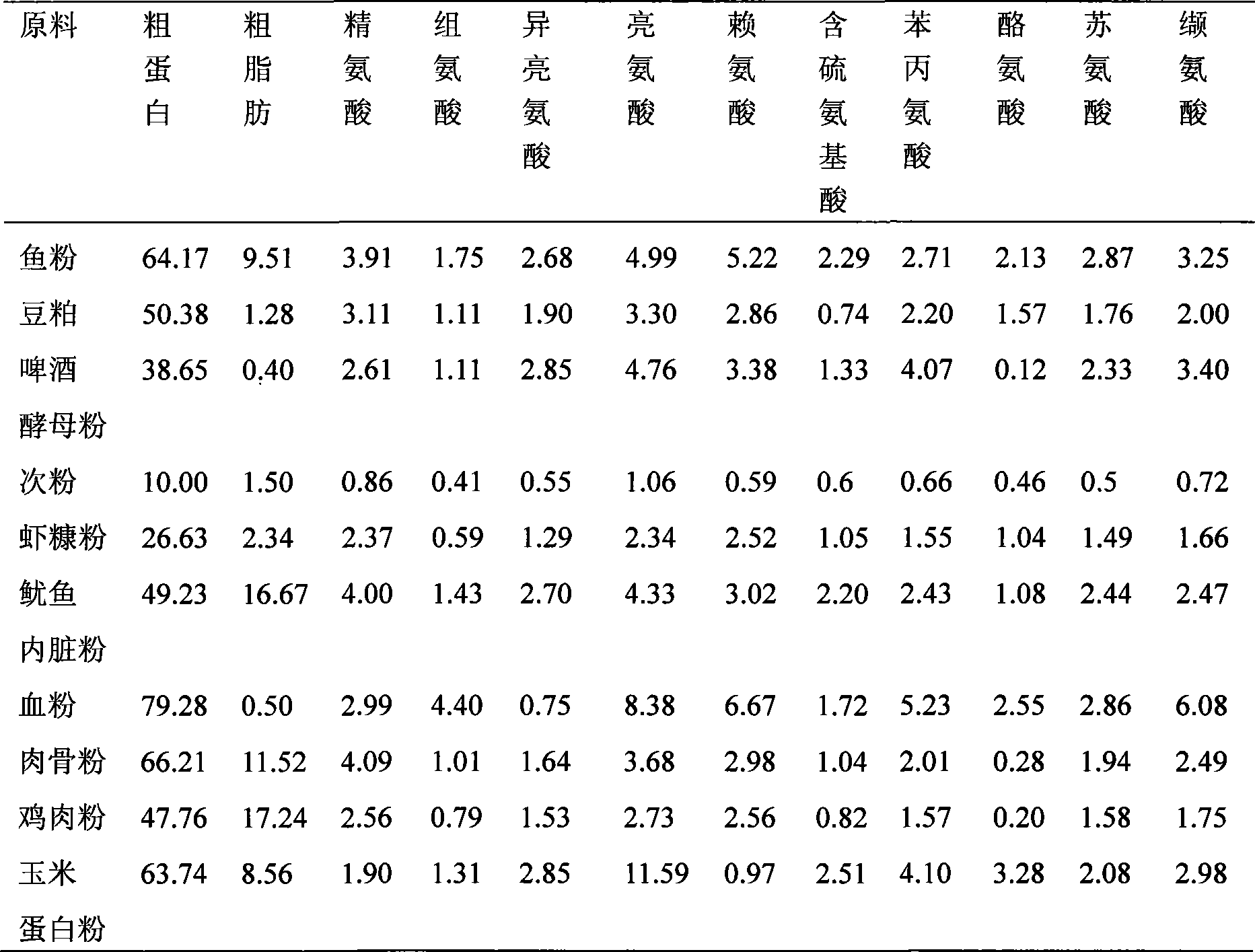

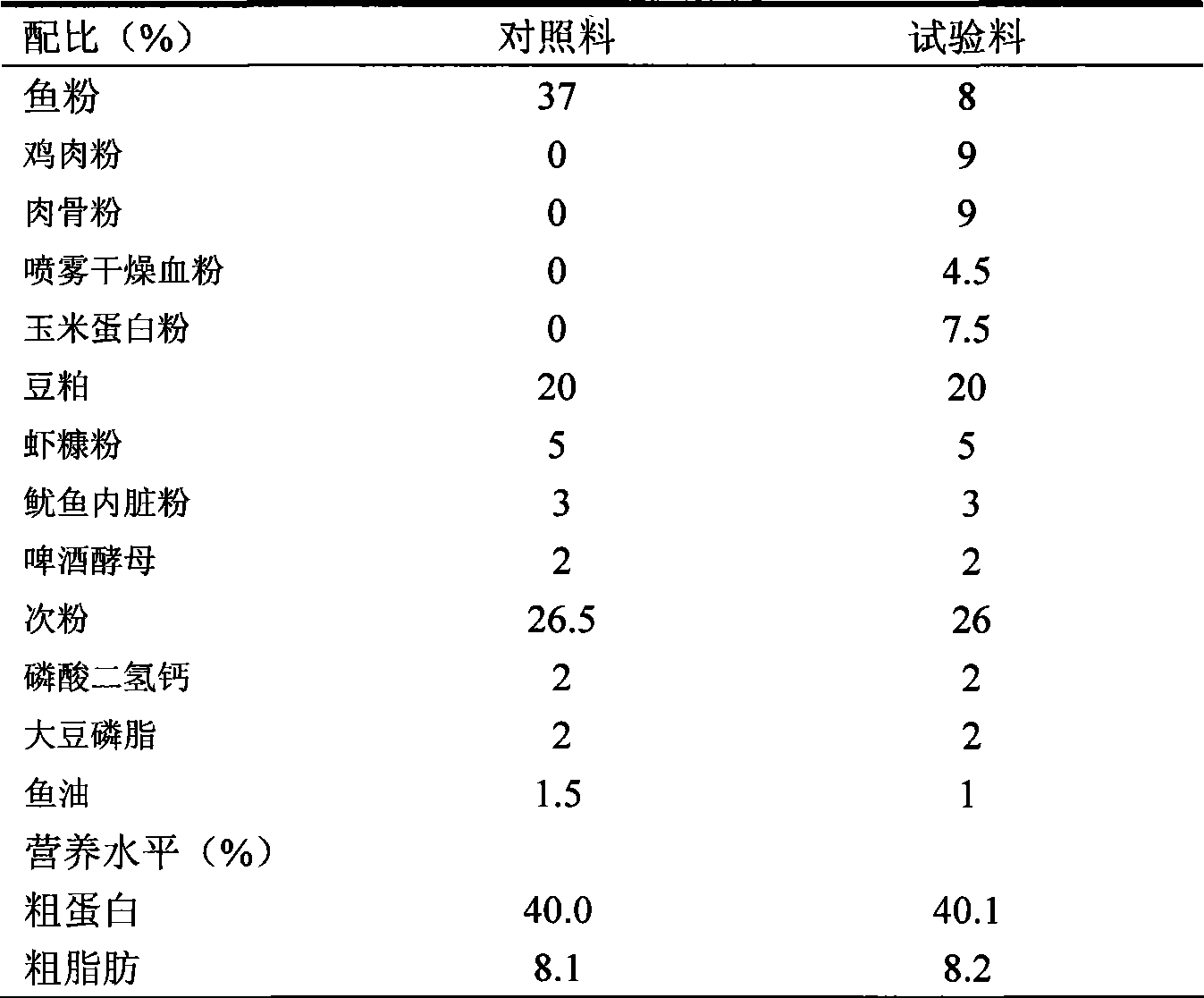

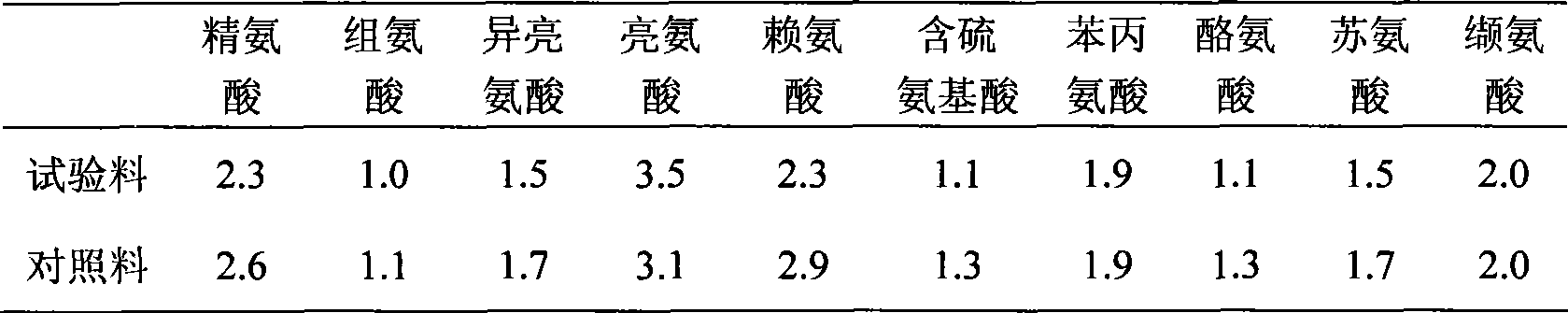

[0022] Example 1: The raw material composition of shrimp compound feed and its content by mass percentage are fish meal 8%, soybean meal 20%, corn gluten meal 7.5%, brewer's yeast 2%, chicken meal 9%, meat and bone meal 9%, blood meal 4.5% , squid viscera powder 3%, shrimp bran powder 5%, soybean lecithin 2%, fish oil 1%, calcium dihydrogen phosphate 2%, feed additive premix 1% (of which, prawn multidimensional premix 0.1%, prawn compound trace 0.2% elemental premix, 0.1% taurine, 0.2% betaine, 0.05% vitamin C, 0.15% choline chloride, 0.2% wheat bran), 26% subflour. During the preparation, the raw materials are pulverized, passed through a 60-mesh sieve, mixed and granulated to prepare the shrimp compound feed.

[0023] The comparative feeding experiment 1 of shrimp compound feed is given below. Using the above-mentioned feed formula, a compound feed with high protein level and low fishmeal was prepared, and the feeding effect test of Penaeus white shrimp was carried out. Pr...

Embodiment 2

[0034] Similar to Example 1, the difference is that the raw material composition of the shrimp compound feed and its content by mass percentage are fish meal 8%, soybean meal 25%, corn gluten meal 10%, brewer's yeast 3%, chicken meal 15%, meat and bone meal 7% %, spray-dried blood meal 3%, squid viscera powder 4%, shrimp bran powder 4%, soybean lecithin 1.5%, fish oil 1%, calcium dihydrogen phosphate 1.5%, feed additive premix 1% (among them, prawn multidimensional premix 0.06% of raw material, 0.1% of prawn compound trace element premix, 0.2% of taurine, 0.3% of betaine, 0.04% of vitamin C, 0.2% of choline chloride, 0.1% of wheat bran), and 16% of subflour. During preparation, each raw material after pulverization is passed through a 60-mesh sieve.

Embodiment 3

[0036] Similar to Example 1, the difference is that the raw material composition of the shrimp compound feed and its content by mass percentage are 10% fish meal, 23% soybean meal, 7% corn gluten meal, 2% brewer's yeast, 5% chicken meal, and 6% meat and bone meal. %, spray-dried blood meal 2%, squid viscera powder 3%, shrimp bran powder 6%, soybean lecithin 1%, fish oil 1.5%, calcium dihydrogen phosphate 1%, feed additive premix 1.5% (among them, prawn multidimensional premix 0.1% of raw material, 0.125% of prawn compound trace element premix, 0.4% of taurine, 0.2% of betaine, 0.02% of vitamin C, 0.1% of choline chloride, 0.555% of wheat bran), and 31% of secondary flour. During preparation, each raw material after pulverization is passed through a 60-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com