Method for producing pickled cucumber can

A production method and technology of pickled cucumbers, applied in the fields of application, food preparation, food science, etc., can solve the problems of excessive metal salt dosage, unnatural color, and not being widely accepted, so as to promote the adjustment of agricultural and rural economic structure, Natural color and the effect of increasing employment opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

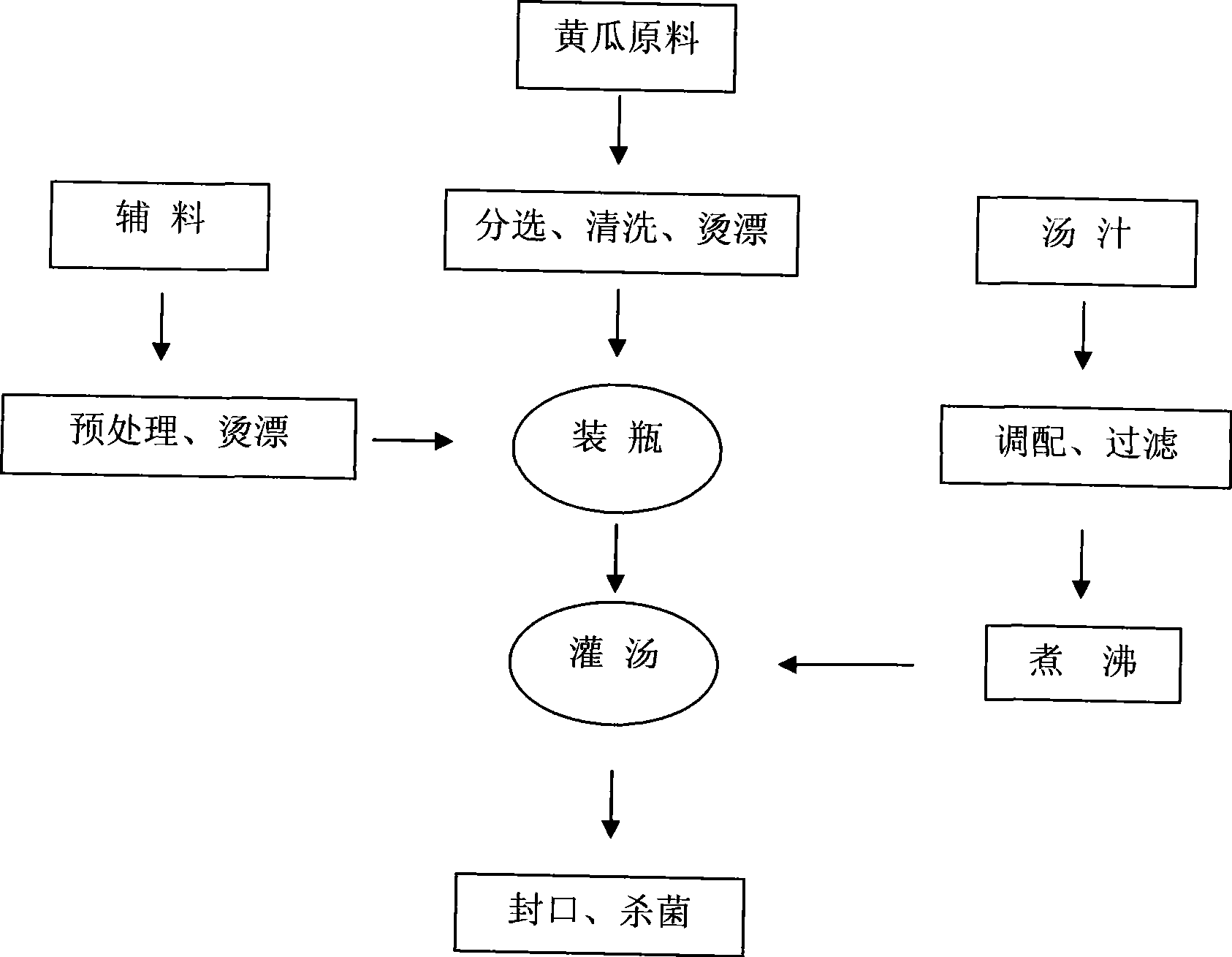

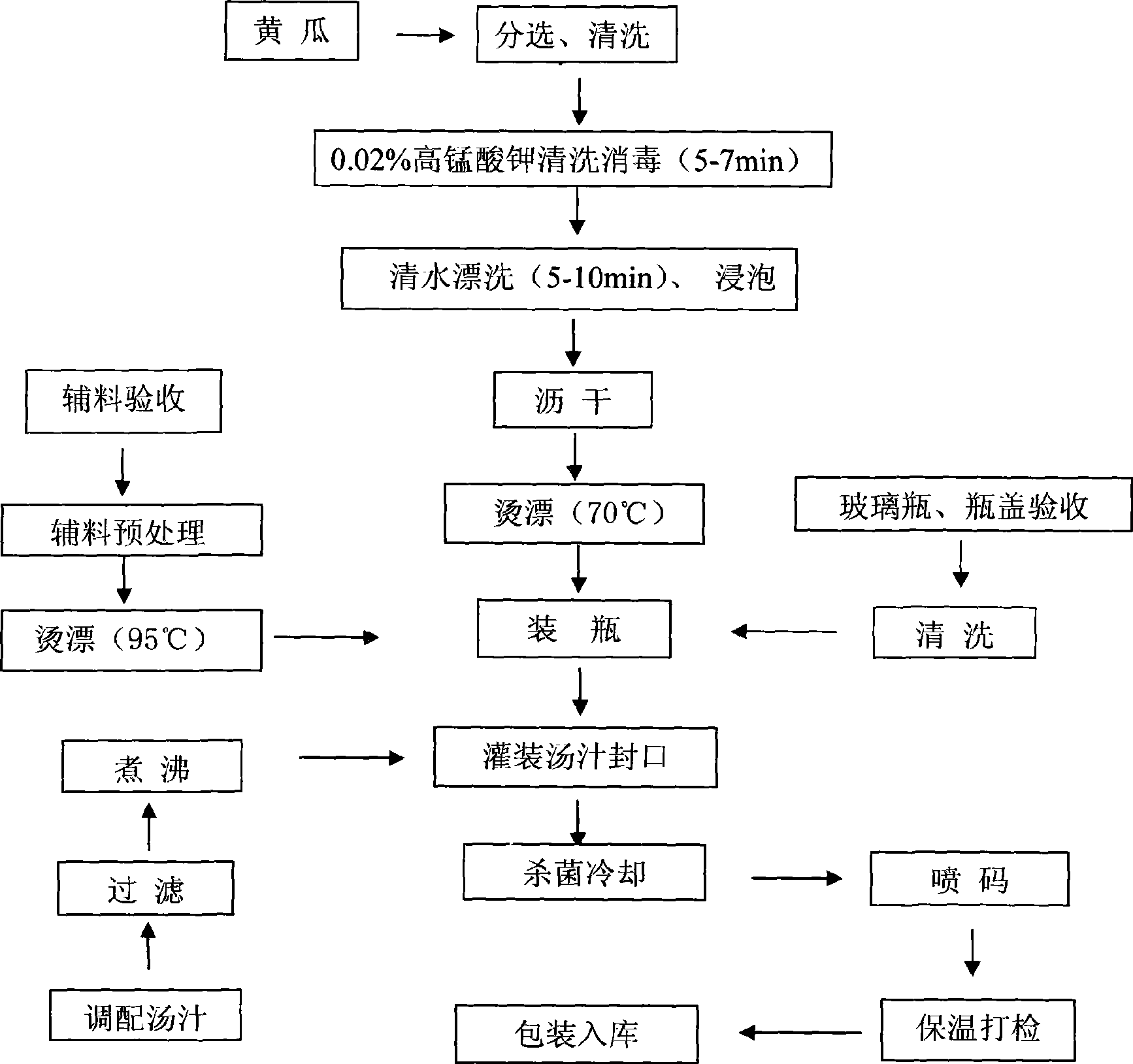

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: choose long 8cm below, the cucumber below thick 2.5cm as raw material, reject insect damage and damage rotten, unqualified raw material such as bending, rinse clean in flowing water; Put the clean raw material into 0.01-0.03% high Soak in potassium manganate solution for 5-7 minutes, rinse with running water immediately; then immerse in the water tank for 6-10 hours and then spray wash, control the moisture adsorbed on the surface in the screen; after controlling the water, put it in 70 Blanch in a sandwich pot at ℃ for 6-8 minutes. After blanching, control the water temperature and bottle immediately; bottle 7-12 sticks, each bottle contains 350g-430g.

[0011] Prepare spice accessories: 700g of cucumber per bottle, 0.1g of mustard seeds, 0.06g of black pepper, and 1 slice of red pepper. 1 slice green chili pepper. 6g of fresh fennel, 6g of fresh horseradish juice, 1 piece of dried bay leaf, 1-2g of garlic, 20-25g / bottle of 7 kinds of spices in total; ba...

Embodiment 2

[0023] Choose cucumber varieties with no thorns or few thorns. Fresh raw materials with a maturity of 70% to 80% are required. The melon strips are required to be tender, uniform in thickness, free from pests and diseases, free from rot, uniform in color, and complete in fruit shape. The qualified raw materials are classified according to size, color and maturity, and the japonica is manually removed to remove rotten and deteriorated raw materials. Wash the sorted raw materials with running water to remove surface soil and impurities. After the raw materials are cleaned, put the rinsed fennel into the bottle first, then put the raw materials into the bottle until it is full, but leave a head space of 6-8 mm, use 65 - Blanch in hot water at 75°C for 3 minutes. When bottling, it is necessary to ensure that the weighing is accurate, and the error is controlled within the range allowed by the quality standard. After filling the bottle, boil the prepared various auxiliary materia...

Embodiment 3

[0027]Example 3: Grow Russian cucumbers planted in sunlight, with thorns and protrusions on the surface, 6-11 cm in length, 3-5 cm in diameter, and make 700 grams of bottles. Recipe: 350 grams of cucumbers, 1 gram of cinnamon leaves, and 1 gram of blackcurrant leaves , 20 grams of garlic, 1 gram of black pepper, 10 grams of fennel, 1 gram of cloves, 20 grams of salt, 15 grams of sugar, 2 grams of red pepper, 7 grams of 76% vinegar, and 300 grams of water.

[0028] Process flow: material selection→cleaning→bottling→100℃ hot water blanching for 10min→canning→sealing→inversion sterilization→cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com