Transfer paper for dry transfer printing and method of dry transfer printing with the same

A transfer paper, transfer printing technology, applied in dyeing method, process for producing decorative surface effects, printing and other directions, can solve the problems of low practical value, increased production cost, lack of reproducibility, etc., to achieve practicality High value, environmental protection, firm feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

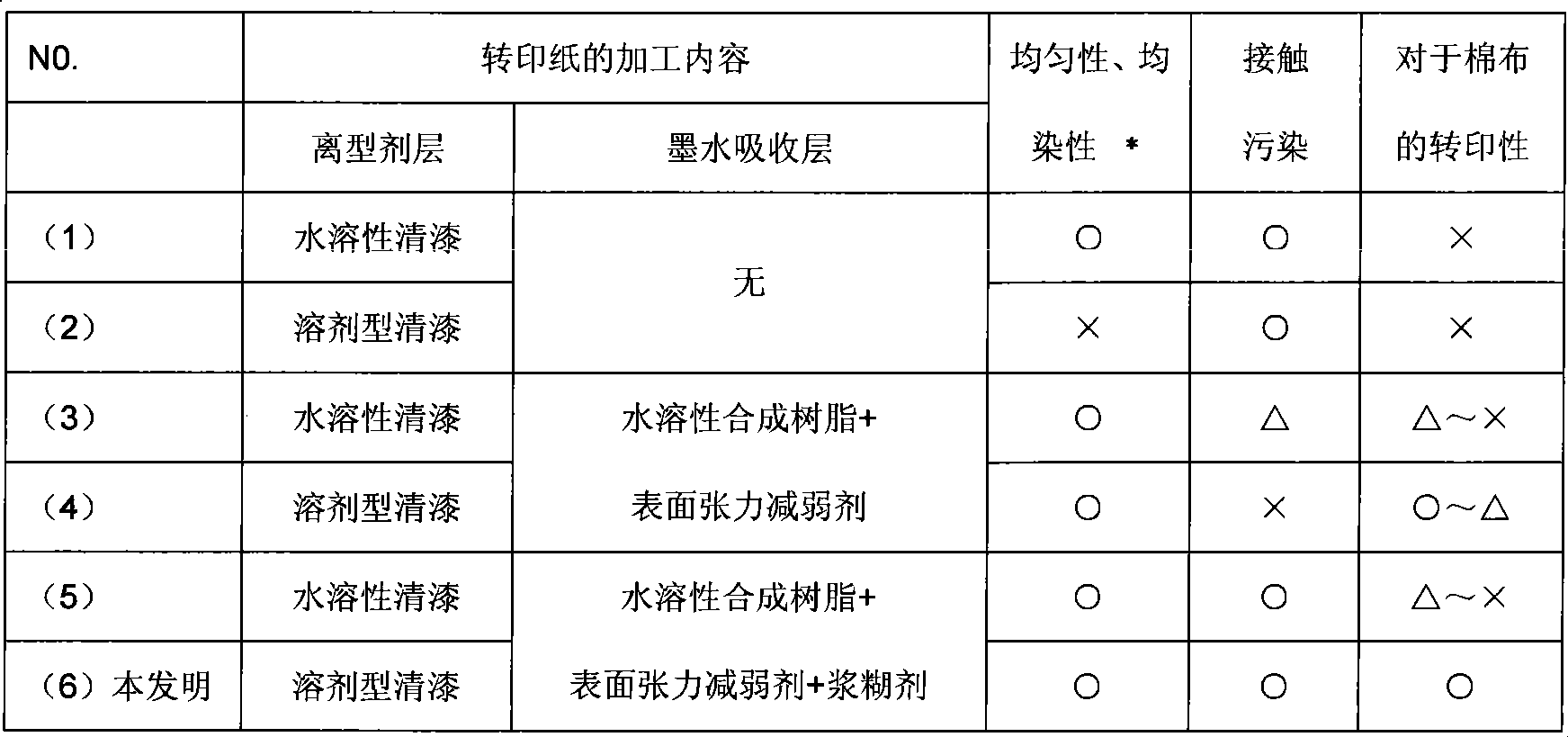

Examples

Embodiment 1

[0099] Use organic solvent varnish (phenol resin 30%, ethyl cellulose 3%, calcium carbonate 10%, clay 10%, ethyl acetate) as a release agent layer on the transfer paper (weight 90g / m2, thickness 0.2mm). 47%) is coated with a machine for coating processing, and after drying, it is subjected to a high-temperature setting treatment at a temperature of 140° C. for 3 minutes. The thickness of the release agent layer was 30 μm.

[0100] Next, as the ink-absorbing layer, PLASCOAT Z-221 (hydrophilic synthetic resin: 25% dispersion of water-soluble polyester resin: made by Huoying Chemical Industry Co., Ltd.) 55% and BINDER TFG-218 (for foil transfer Polyamide resin paste: Matsui Pigment Chemical Industry Co., Ltd.) 10%, MEISANOL TR (negative ion surfactant: Meisei Chemical Industry Co., Ltd.) 1%, soda ash (alkaline agent for reactive dye fixing) 3%, ε-caprolactam 5%, thiourea 3%, ECOALGIN MS (hydrophilic paste: 5% paste of sodium alginate: made by Andaruhime Co., Ltd.) 15%, thickener...

Embodiment 2

[0105] As base paper for transfer, commercially available polyethylene composite paper (weight 90g / m 2, thickness of 0.2 mm), as the ink absorbing layer, 50% of HA RESIN PE-1B (hydrophilic synthetic resin: water-soluble urethane-modified ether-type resin 25% viscous solution: Meisei Chemical Industry Co., Ltd.) 50%, BINDER TFG -1215 (polyamide resin paste for foil transfer: manufactured by Matsui Pigment Chemical Industry Co., Ltd.) 15%, PLASCOAT RY-2 (10% solution of fluorine-based surface tension reducing agent: manufactured by Hoyo Chemical Industry Co., Ltd.) 0.5% , potassium carbonate (alkaline agent for reactive dye fixation) 2.5%, thiourea (moisturizing agent for dyeing promotion) 7%, SORUBITORZE C-5 (hydrophilic paste: paste for temporary fixation of printing dye: etherification 10% paste of starch paste: AVEBE Co., Ltd.) 18%, thickener-F (acryl-based synthetic paste: viscosity modifier: Sano Co., Ltd.) 2% (the remainder is adjusted with water) Make a 100% mixture (co...

Embodiment 3

[0109] In transfer paper (weight 70g / m 2 , thickness 0.15mm) as a release agent layer with organic solvent varnish after processing, as the ink absorbing layer, use the concentration of 10% ALCOX E-30 (hydrophilic synthetic resin: water-soluble polyethylene oxide resin: Meisei Chemical Industry Co., Ltd.) 51.5%, PLASCOAT Z-850 (hydrophilic synthetic resin: 25% dispersion of water-soluble polyester resin: Hoyo Chemical Industry Co., Ltd.) 15%, P-TOPINK (polyamide for hair fixing) Resin paste: manufactured by Matsui Pigment Chemical Industry Co., Ltd.) 10%, anti-hydrophobic agent-1004 (negative ion active agent type surface tension reducer: manufactured by Sano Co., Ltd.) 1.5%, soda ash (alkaline agent for reactive dye fixing) 3% , ε-caprolactam (moisturizing agent for dyeing promotion) 5%, ECOALGIN MS (hydrophilic paste: paste for temporarily fixing printing dye: 5% paste of sodium alginate: manufactured by Andaru Hime Co., Ltd.) 10% , Tackifier-F (Acryl-based synthetic resin:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com