Hydrophobicity visible-light response type nano TiO2 photocatalyst and preparation method thereof

A photocatalyst and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of slow reaction rate, limited application, and low photocatalytic quantum efficiency and other issues to achieve the effect of improving quantum utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

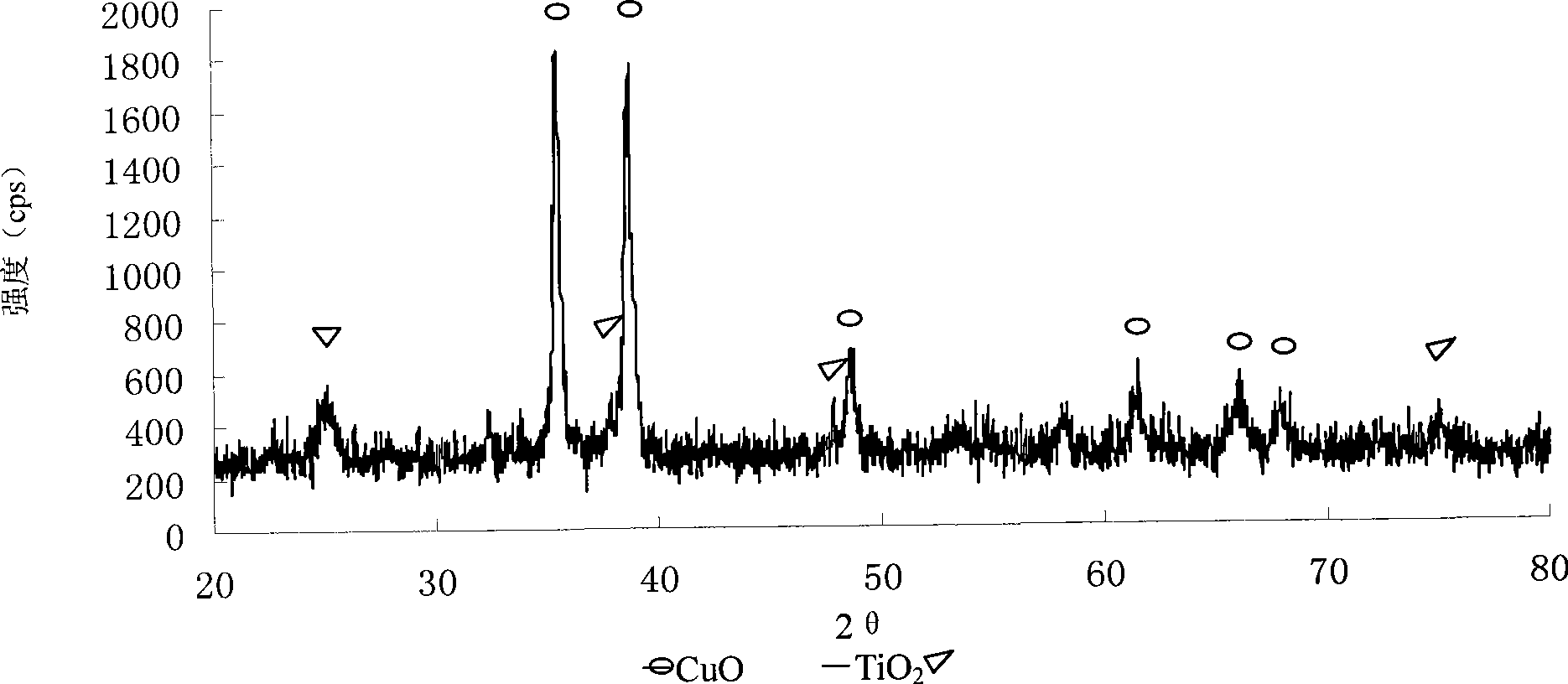

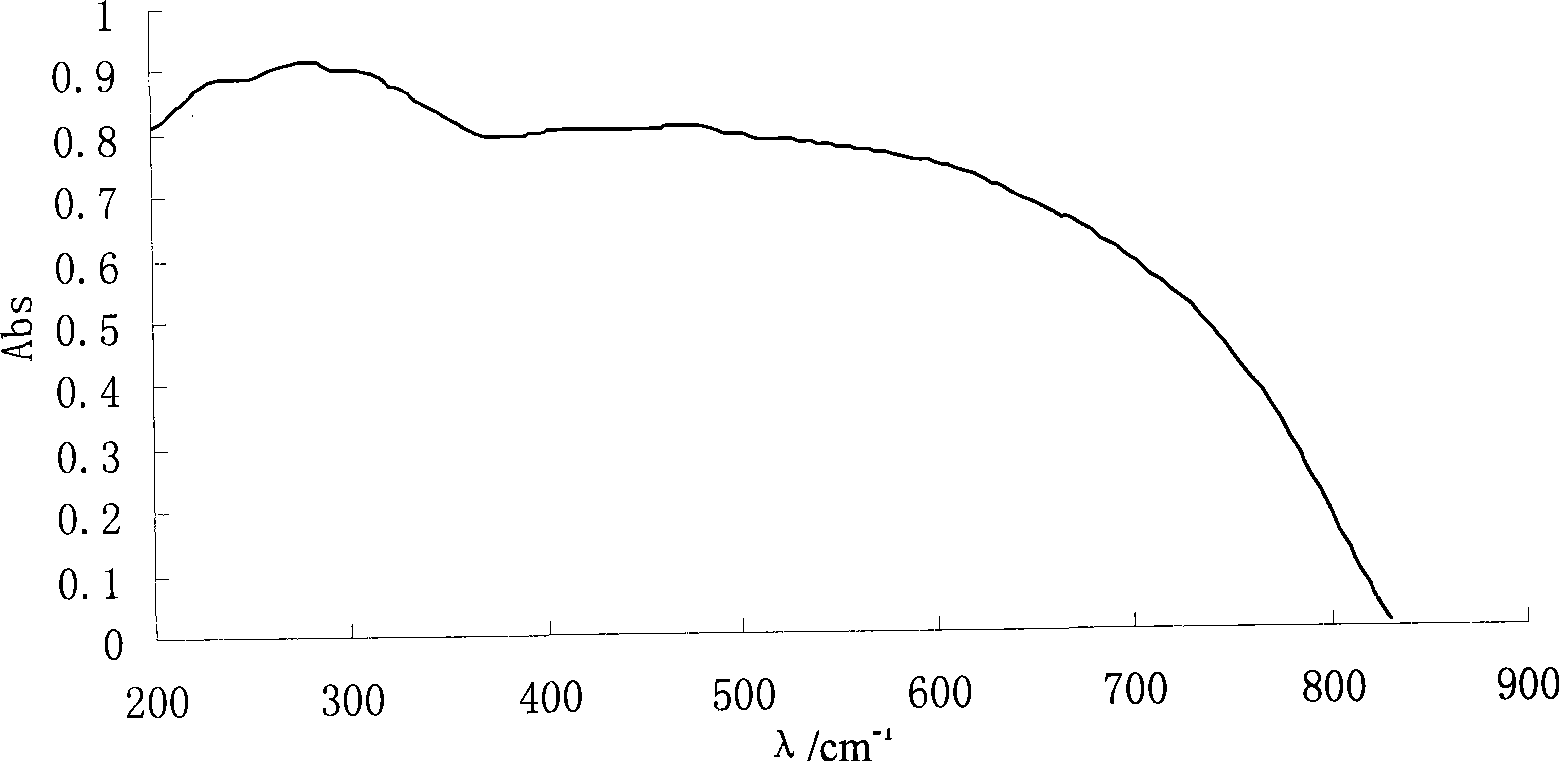

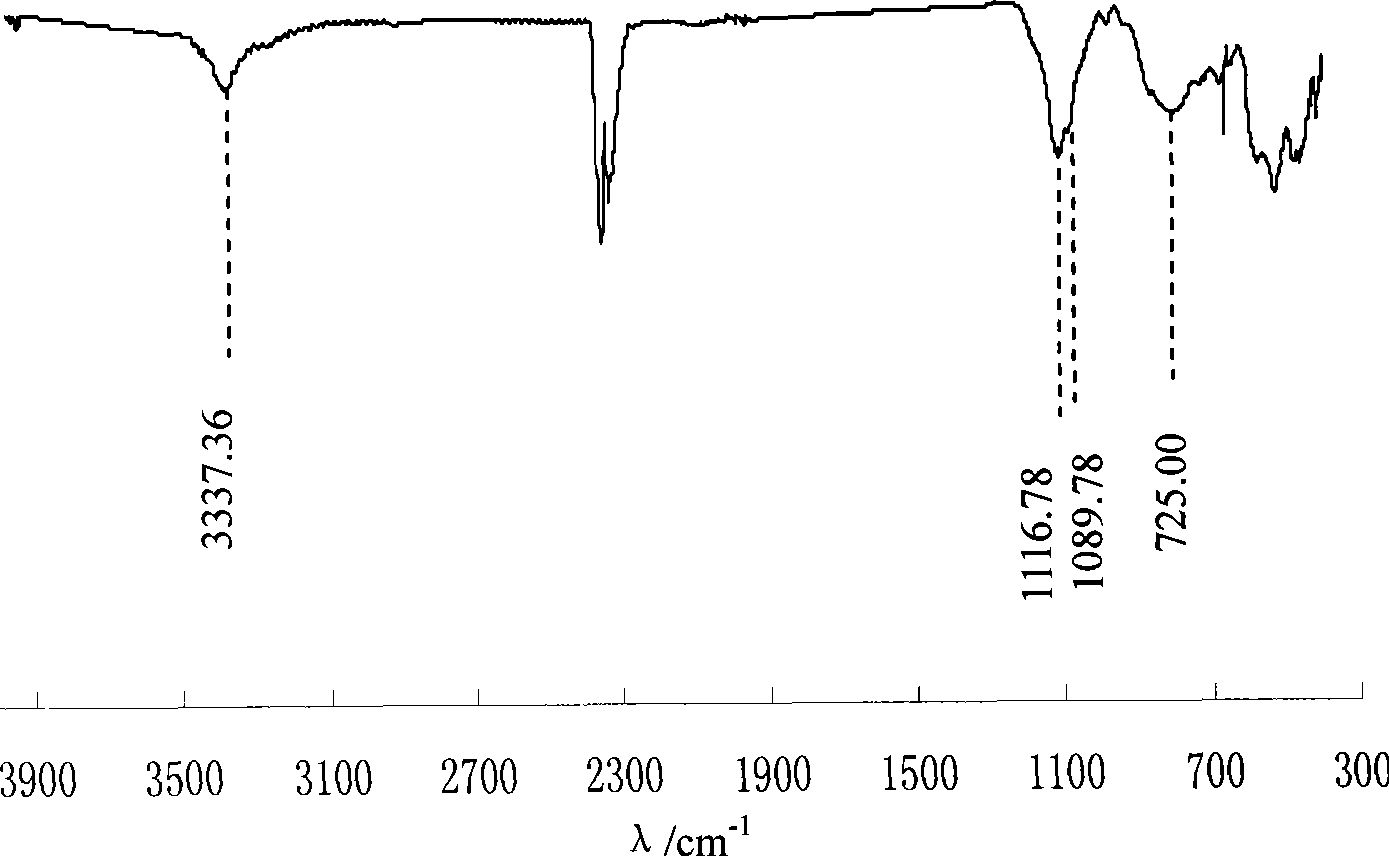

[0032] Embodiment 1: SDS load is 0.2g / g TiO 2 , the CuO loading is 0.8g / g TiO 2 Hydrophobic visible light responsive TiO 2 Preparation process of photocatalyst material:

[0033] Measure 10ml of tetra-n-butyl titanate and 30ml of absolute ethanol to make stock solution, weigh 0.5gSDS, 6.05gCu(NO 3 ) 2· 3H 2 O was made into 10ml solutions respectively, and 20ml and 7.5ml of absolute ethanol and glacial acetic acid were measured respectively, and mixed with Cu(NO 3 ) 2 solution and SDS solution together to form a titration solution;

[0034] Preparation method 1: drop method

[0035] Under vigorous stirring at 20°C-30°C, slowly drop the titration solution into the original solution, and continue stirring for 30 minutes after the titration is completed.

[0036] Aged at room temperature for 1 day, dried in an oven at 100°C to 105°C, ground, passed through a 200-mesh sieve, and placed in N at 400°C 2and air atmosphere for 4h (heating rate of 2.5 ° C / min), the obtained c...

Embodiment 2

[0041] Embodiment 2: SDS load is 0.92g / g TiO 2 , the CuO loading is 3.2g / g TiO 2 Hydrophobic visible light responsive TiO 2 Preparation process of photocatalyst material:

[0042] Measure 10ml of tetra-n-butyl titanate and 40ml of absolute ethanol to make a stock solution, weigh 2.3g of SDS, 24.2g of Cu(NO 3 ) 2· .3H2O was made into 15ml and 20ml solutions respectively, measured absolute ethanol, glacial acetic acid 40ml and 15ml respectively, and mixed with Cu(NO 3 ) 2 solution and SDS solution together to form a titration solution;

[0043] Preparation method 1: drop method

[0044] Under vigorous stirring at 20°C-30°C, slowly drop the titration solution into the original solution, and continue stirring for 45 minutes after the titration is completed. Aged at room temperature for 2 days, dried in an oven at 100°C to 105°C, ground, passed through a 200-mesh sieve, and placed in N at 450°C 2 Calcined in air atmosphere for 5h (heating rate: 2.5°C / min), the obtained cata...

Embodiment 3

[0049] Embodiment 3: SDS load is 2g / g TiO 2 , the CuO loading is 8g / g TiO 2 Hydrophobic visible light responsive TiO 2 Preparation process of photocatalyst material:

[0050] Measure 10ml of tetra-n-butyl titanate and 60ml of absolute ethanol to make stock solution, weigh 5gSDS, 60.5gCu(NO 3 ) 2· 3H 2 O was made into 30ml and 40ml solutions respectively, measured absolute ethanol, glacial acetic acid 80ml and 30ml respectively, and mixed with Cu(NO 3 ) 2 solution and SDS solution together to form a titration solution;

[0051] Preparation method 1: drop method

[0052] Under vigorous stirring at 20°C-30°C, slowly drop the titration solution into the stock solution, and continue stirring for 60 minutes after the titration is completed. Aged at room temperature for 2 days, dried in an oven at 100°C to 105°C, ground, passed through a 200-mesh sieve, and placed in N at 500°C 2 and air atmosphere for 6h (heating rate of 2.5 ° C / min), the obtained catalysts were recorded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com