Modified polyolefin material and special modified resin and their preparation methods

A polyolefin and polycondensation resin technology, applied in the production of bulk chemicals, etc., can solve the problems of no polyolefin composite material, inability to uniformly disperse inorganic particles, and use restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, preparation polynuclear aromatic polycondensation resin

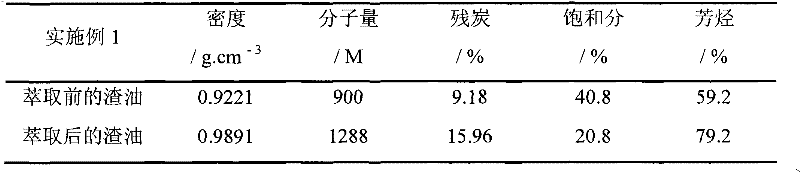

[0024] The vacuum residue and furfural solvent were mixed at a volume ratio of 1:2, stirred at 80°C for 25 minutes, and then settled, and the solution was divided into upper and lower layers. Separation with a separatory funnel, the lower layer is the extraction phase, and the aromatic-rich fraction is obtained after the solvent is removed by distillation. The physical and chemical properties of the residual oil before and after extraction are shown in Table 1.

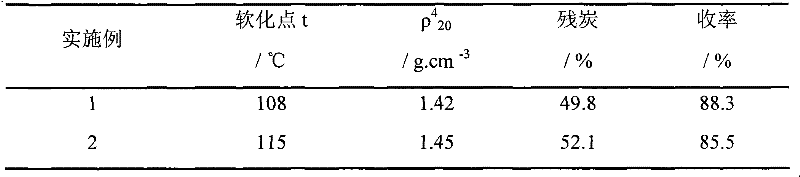

[0025] Take 20g of the above aromatic-rich fraction, 20g of benzaldehyde, and 2g of p-toluenesulfonic acid, and mix them in a container. The condensation polymerization reaction was carried out under magnetic stirring and nitrogen protection, and the reaction temperature was 170°C. A large amount of gas is generated during the reaction, and when the system visibly becomes viscous and no bubbles are generated, the reaction is terminated to...

Embodiment 2

[0030] Embodiment 2, preparation polynuclear aromatic polycondensation resin

[0031] Get 20g of aromatic-rich components of Example 1, 20g of benzaldehyde, and 2.8g of p-toluenesulfonic acid, and mix them in a container. Under magnetic stirring and nitrogen protection, the condensation polymerization reaction was carried out at a temperature of 180°C. A large amount of gas is generated during the reaction, and when the system visibly becomes viscous and no bubbles are generated, the reaction is terminated to obtain the polynuclear aromatic polycondensation resin provided by the invention. The physical and chemical properties of the resin are shown in Table 2.

Embodiment 3

[0032] Embodiment 3, preparation polynuclear aromatic polycondensation resin

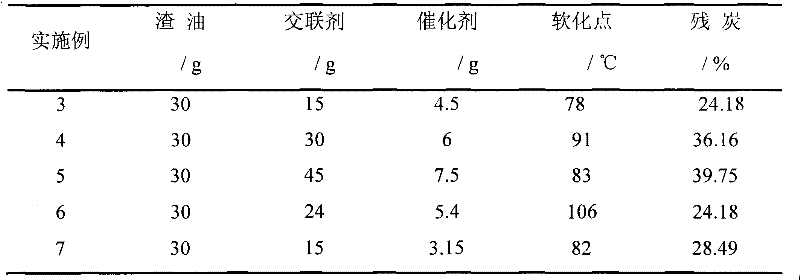

[0033]Take 30g of vacuum residue, without extraction, directly carry out condensation polymerization reaction with cross-linking agent benzaldehyde under the catalysis of p-toluenesulfonic acid. Benzaldehyde is 15g, and p-toluenesulfonic acid content is 4.5g, selects the reaction and stirs evenly at 200 ℃, under nitrogen protection, obtains the product that contains more light components, through solvent (acetone: the volume ratio of dehydrated alcohol is 1:1 mixed solution) to obtain the polynuclear aromatic polycondensation resin provided by the present invention (ie B-stage COPNA resin). The physical and chemical properties of the resin are shown in Table 3.

[0034] Table 3 Physicochemical properties of polynuclear aromatic polycondensation resins prepared in Examples 3-7

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com